MODELS:

Actuator Only:

VC2, VC4, VC60, VC8 (See Table 1)

Bodies (Order Separately):

VCZ..., (See 95C-10919)

Actuators

Model No.

Power

Control

Input

Auxiliary

Switch

Special

Features

INTERNATIONAL MODEL [4]

VC2010zz00

24V~50Hz

SPDT

- -

Molex

VC2011zz00

24V~50Hz

SPDT

- -

Cable

VC2012zz00 [1]

24V~50Hz

SPDT

- -

Molex

VC2611zz00

24V~50Hz

SPDT

Yes

Cable

VC4012zz00

200-240V~50-60Hz

SPST

- -

Molex

VC4013zz00

200-240V~50-60Hz

SPST

- -

Cable

VC4013zz11 [3] 200-240V~50-60Hz

SPST

- -

Cable

VC4613zz00

200-240V~50-60Hz

SPST

Yes

Cable

VC6012zz00

200-240V~50-60Hz

SPDT

- -

Molex

VC6013zz00

200-240V~50-60Hz

SPDT

- -

Cable

VC6013zz11 [3] 200-240V~50-60Hz

SPDT

- -

Cable

VC6612zz00

200-240V~50-60Hz

SPDT

Yes

Molex

VC6613zz00

200-240V~50-60Hz

SPDT

Yes

Cable

VC8011zz00

24V~50Hz

SPST

- -

Cable

VC8611zz00

24V~50Hz

SPST

Yes

Cable

NORTH AMERICA MODELS [4]

VC2114zz11 [3]

24V~60Hz

SPDT

-

Plenum[2]

VC2714zz11 [3]

24V~60Hz

SPDT

Yes

Plenum[2]

VC4011zz11 [3]

120V~60Hz

SPST

- -

Cable

VC4013zz11 [3] 200-240V~50-60Hz

SPST

- -

Cable

VC8111zz11 [3]

24V~60Hz

SPST

- -

Cable

VC8114zz11 [3]

24V~60Hz

SPST

-

Plenum[2]

VC8711zz11 [3]

24V~60Hz

SPST

Yes

Cable

VC8714zz11 [3]

24V~60Hz

SPST

Yes

Plenum[2]

NOTE:

[1] with Snubber circuit

[2] Plenum rated with 1.5 meter cable

[3] Model number ending with "11" has conformal coated printed circuit

board for heating/cooling use.

[4] Some models are not available in all countries. Not all VC Actuator

modes are shown.

Table 1 - Actuator Model Identifiers

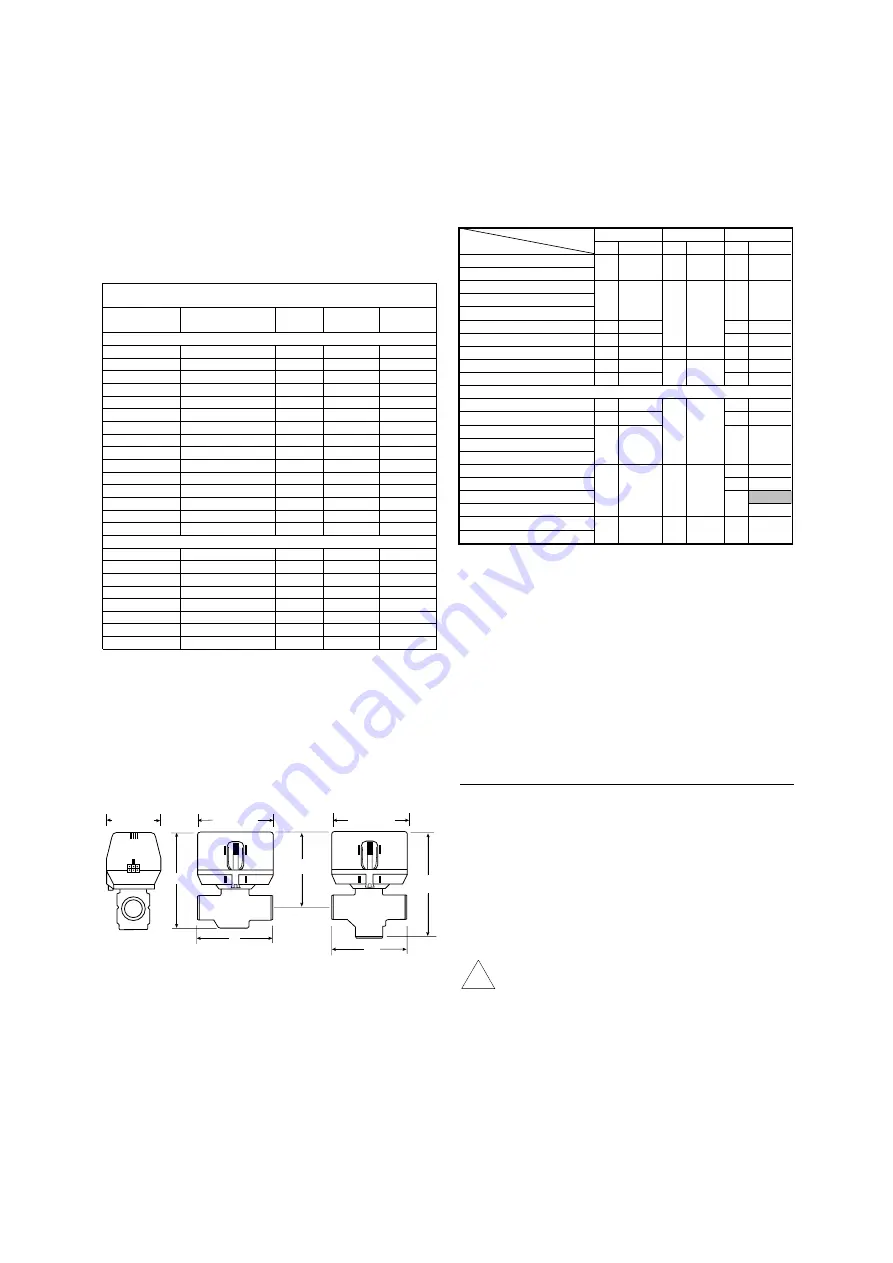

VC Valve Assembled dimensions for reference (Figure 1 & Table 2):

94 [3-3/4]

68 [2-3/4]

94 [3-3/4]

Figure 1 - Nominal dimensions in inches and millimetres

A

B

B

AB

A

D

90 [3-9/16]

C

C

E

[4]

Dimensio n

Pipe Fitting Sizes

C

D

E

mm

Inches

mm

Inches

mm

Inches

1/2" BSPP (int.) [2]

98

3-7/8 111 4-3/8 136 5-11/32

1/2" BSPT (int.)

3/4" BSPP (int.)

94 3-11/16

113 4-7/16

130 5-1/8

3/4" BSPT (int.)

3/4" BSPP (ext.)

22mm Compression [3]

112 4-7/16

140 5-1/2

1" BSPP (int.)

94 3-11/16

136 5-11/32

1" BSPP (ext.)

95 3-11/17114 4-7

/171375-11/33

1" BSPT (int.)

94 3-11/16

113 4-7/16

136 5-11/32

28mm Compression [3]

116 4-9/16

1475-13/16

NORTH AMERICA STANDARD MODELS

3/8" FLARE [1]

98

3-7/8

111 4-3/8

136 5-11/32

1/2" SWEAT

89

3-1/2

130 5-1/8

1/2" FLARE [1]

98

3-7/8

136 5-11/32

1/2" INVERTED FLARE [1]

1/2" NPT (int.)

3/4" NPT (int.)

94 3-11/16 113 4-7/16

130 5-1/8

3/4" SWEAT

132

136

5-3/16

5-11/32

1" NPT (int.)

1" SWEAT

1-1/4" SWEAT

110 4-5/16 118 4-5/8 142 5-5/8

1-1/4" NPT (int.)

[1] No adapters

[2] Suitable for use as15 mm compression fitting

[3] Dimensions shown with nuts and olives installed

[4]

Some models not available in all countries

Table 2 - VC Valve assembled dimensions

MANUAL OPENER

The manual opener can be manipulated only when in the up position.

The motorized valve can be opened by firmly pushing the red manual

lever down to midway and in. This holds the valve in the open

position. This "manual open" position may be used for filling, venting,

draining the system or for opening the valve in case of power failure.

The valve can be restored manually to the closed position by

depressing the red manual lever lightly and then pulling the lever out.

The valve and actuator will return to the automatic position when

power is restored.

NOTE

: If the valve is powered open (the lever is down), it can not be

manually closed unless actuator is removed.

INSTALLATION

WHEN INSTALLING THIS PRODUCT:

1. Read these instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the product to

make sure the product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. Always conduct a thorough checkout when installation is com

pleted.

5. While not necessary to remove the actuator from the body, it can

be removed for ease of installation. The actuator can be installed

in any position to suit the most convenient wiring mode.

6. An extra 1" (25 mm) head clearance is required to remove the

actuator.

!

CAUTION:

Disconnect power supply before connecting wiring to prevent

electrical shock and equipment damage.

On 24 V systems,

never

jumper the valve coil terminals, even

temporarily. This may damage the thermostat.

2