PLUMBING

Refer to the VC Series Cartridge Valve Installation and Instruction

sheet, form number 95C-10919, for plumbing instructions.

!

IMPORTANT:

For trouble-free operation of the product, good installation

practice must include initial system flushing, chemical

water treatment, and the use of a 50 micron (or finer)

system side stream filter(s). Remove all filters before

flushing.

Put the VC actuator manual lever in the manual open or the

fully open (down) position to allow initial system flushing with

the actuator mounted. This may be done without electrical

hook-up. Alternatively, reusable flush caps, part # 272866B,

may be purchased separately for use in initial flushing of dirty

hydronic systems.

Do not use boiler additives, solder flux and wetted

materials which are

petroleum based or contain mineral

oil, hydrocarbons, or ethylene glycol acetate. Compounds

which can be used, with minimum 50% water dilution, are

diethylene glycol, ethylene glycol, and propylene glycol

(antifreeze solutions).

TO INSTALL ACTUATOR

Installation of the actuator does not require draining the system,

provided the valve body and valve cartridge assembly remain in the

pipeline. Wiring may be done either before or after the actuator is

installed.

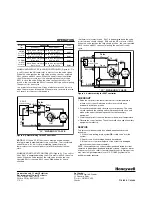

1. The actuator head is automatically latched to the valve. Align the

coupling hole in the bottom of the actuator with the valve stem.

Press the actuator down towards the body with moderate hand force

and turn the actuator counter-clockwise by 1/8 turn (45 degrees) to

line up the actuator with the piping. The latch will click when

engaged. See Figure 2.

NOTE:

The actuator can also be installed at right angles to the valve

body but in this position the latch mechanism will not engage.

2. Connect leadwires. See Figure 3 for flexible conduit installation

with plenum-cable models.

Figure 2 - Latch Mechanism to detach Actuator

4

1

2

3

3/8" flex

conduit

Figure 3 - Flexible Conduit Attachment

WIRING

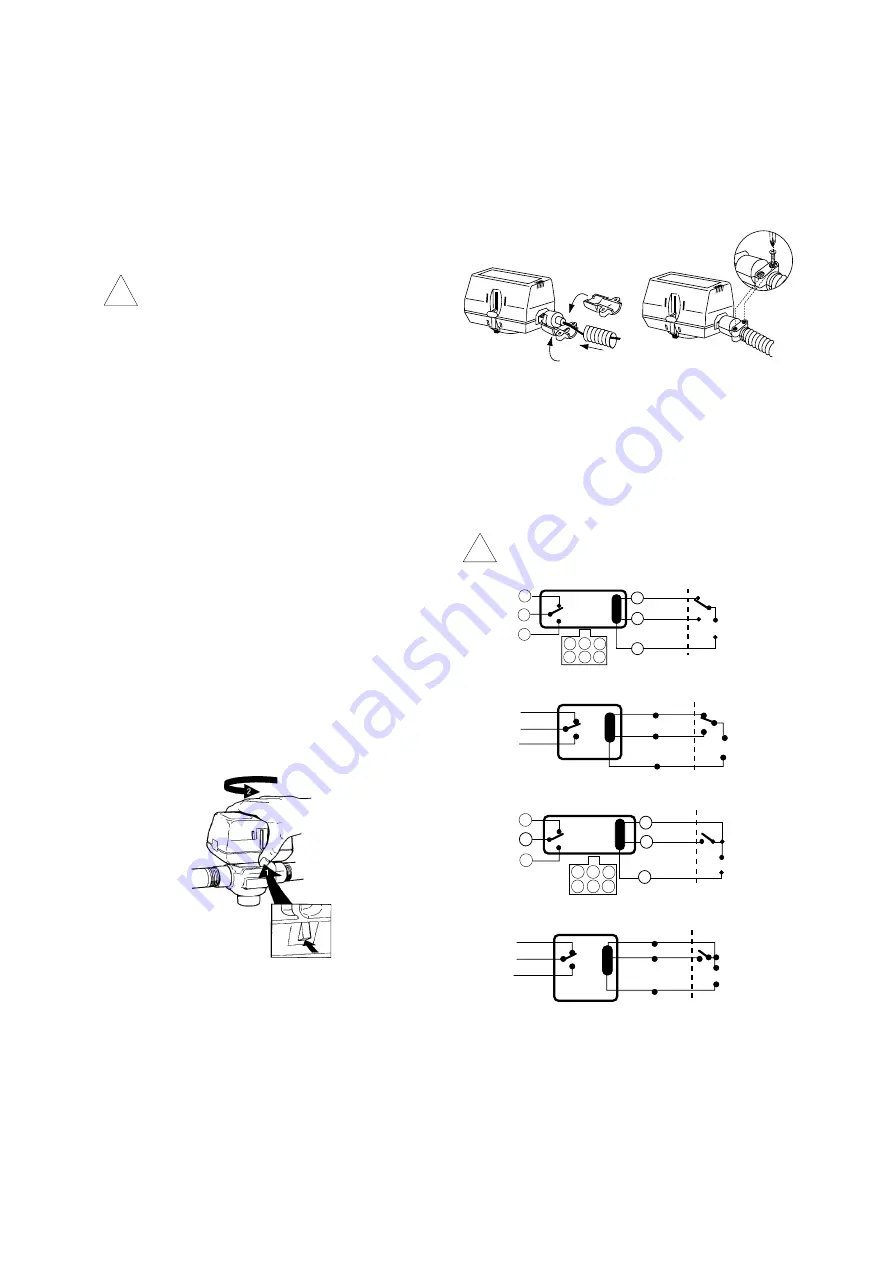

NOTE: Each 3-wire (SPDT) actuator must have individual spdt

controller. Use series 40 or 80 for single controller to control

multiple valves.

Figures 4, 5, 6 and 7 show wiring connections. Port "A"

open and

closed denote valve open and closed positions respectively. On

auxiliary switch models, terminal 4 (grey wire) contact makes at the

end of the Port A opening stroke. On Molex connector models, valve

& auxiliary switch boltage must be the same to meet approval

requirement. For mixed line voltage and 24 VAC (Safety Extra Low

Voltage) application, the cable version is recommended.

!

CAUTION:

Disconnect power supply before connecting wiring to prevent

electrical shock and equipment damage.

5

Port "A"

4

1

*

AUX.SW.

3 2 1

3

Closed

Open

6

2

(3 WIRE)

*

Valve

5 4

6

MODELS

L

~

N

Figure 4 - Wire configuration for MOLEX™ models for

SPDT controller. (Series 20 & 60).

WHITE

BLUE

BLACK

BROWN

*

Open

Closed

Port "A"

Valve

ORANGE

L

GREY

~

(3 WIRE)

N

*

AUX.SW.

MODELS

Figure 5 - Wiring color code for cable models for SPDT

controller. ( Series 20 & 60 )

Port "A"

Closed

Open

L

~

N

*

AUX.SW.

MODELS

1

( 2 WIRE +

COMMON)

*

Valve

5

3

1

2

4

6

2

5

4

6

3

Figure 6 - Wire configuration for MOLEX™ models for SPST

controller. (Series 40 & 80)

BLACK

BROWN

*

Closed

Open

Port "A"

WHITE

Valve

ORANGE

L

GREY

~

( 2 WIRE +

N

*

AUX.SW.

COMMON)

BLUE

MODELS

Figure 7 - Wiring color code for cable models for SPST

controller. ( Series 40 & 80)

3