OPERATION

Actuator

Connection

Valve

Movement

Type

Cable Model

Molex

TM

Model

3-WIRE

(for SPDT

controller)

Blue & Brown energised

Black de-energized

Pin #2 & #3 energised Pin

#6 de-energised

Closes

Blue & Black energised

Brown de-energized

Pin #2 & #6 energised Pin

#3 de-energised

Opens

2 + COM.

(for SPST

controller)

Blue & Brown energised

Black open

Pin #2 & #3 energised Pin

#3 & #6 open

Closes

Blue & Brown energised

Black closed

Pin #2 & #3 energised Pin

#3 & #6 closed

Opens

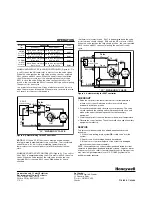

WHEN USED WITH SPDT (3-WIRE) CONTROLLER (Figure 8): On

a call for heat, the NO thermostat contacts close, the valve opens.

When the valve reaches the fully open position, the cam actuated

SW1 closes and SW2 opens. When the need for heat is satisfied

the NC thermostat contacts close, energizing the valve through

SW1 to close the valve. When the valve reaches the fully close

position, the cam actuated SW2 closes and SW1 opens anticipating

the next call for heat cycle.

In a power failure the valve will stay at whatever position it was in

when the power was interrupted. When power is restored, the valve

will respond to the controller demand.

~

AC

MOTOR

CW

CAM

Valve

Close

Open

N

L

"VC "HYDRONIC VALVE

SW1

SW2

S.P.D.T.

CONTROLLER

NC

NO

BROWN

BLACK

BLUE

2

6

3

Figure 8 - Actuator wiring for SPDT controller

NOTE:

VC2114 and VC8114 actuators must be used with sepa

rately-powered (hardwired) electronic controllers. Their sustained

current draw is too low for power stealing (parasitic power)

thermostats or series anticipators of electromechanical thermo

stats.

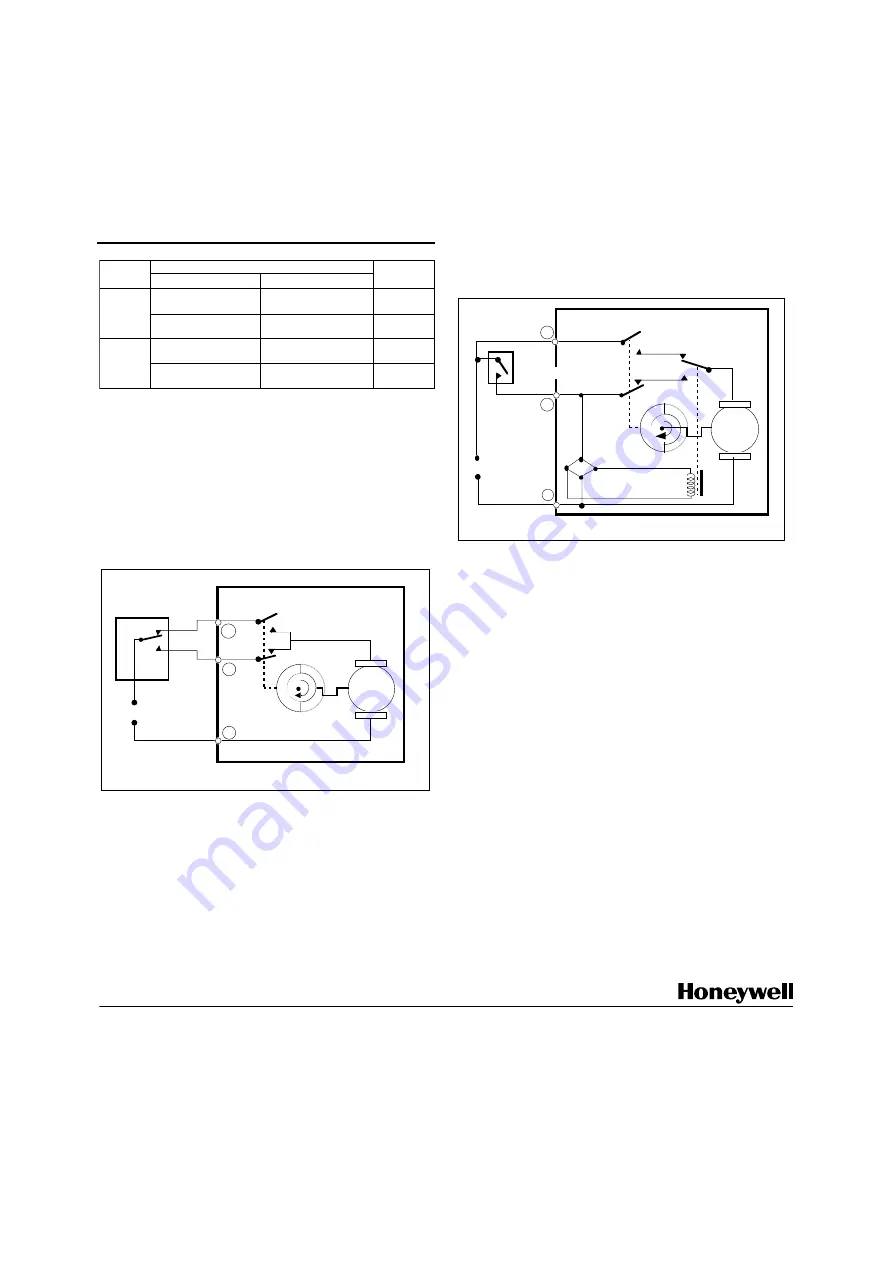

WHEN USED WITH SPST CONTROLLER (Figure 9): On a call for

heat, RLY1 is energized making the NO contacts in SW3, the valve

opens. When the valve reaches the fully open position the cam

operated SW1 closes and SW2 opens. When need for heat is

satisfied,

the thermostat contacts open, RLY1 is de-energized and the valve

motor is driven closed through SW1 and the NC contacts of SW3.

When the valve reaches the fully closed position, the cam operated

SW2 closes and SW1 opens anticipating the next call for heat

cycle.

~

"VC" HYDRONIC VALVE

AC

MOTOR

CW

CAM

RLY1

SW1

SW2

Valve

Close

Open

NC

NO

SW3

BLUE

BROWN

2

N

L

CONTROLLER

6

BLACK

3

S.P.S.T

.

Figure 9 - Actuator wiring for SPST controller

CHECKOUT

1. Raise the set point of the thermostat above room temperature to

initiate a call for heat. Red valve position lever should move

downward to the open position.

2. For auxiliary switch models, observe all control devices. The valve

should open and the auxiliary switch (if present) should close and

make at the end of the opening stroke to activate auxiliary

equipment.

3. Lower the set point of the zone thermostat below room temperature.

4. Observe the control devices. The valve should close and all auxiliary

equipment should stop.

SERVICE

This valve should be serviced by a trained, experienced service

technician.

1. If the valve is leaking, drain system

OR

isolate valve from the

system.

2. Check to see if the cartridge needs to be replaced.

3. If the motor or other internal parts of the actuator is damaged,

replace the entire actuator assembly.

NOTE: Honeywell hydronic valves are designed and tested for silent

operation in properly designed and installed systems. However, water

noises may occur as a result of excessive water velocity. Piping noises

may occur in high temperature (over 212

°

F [100

°

C]) systems with

insufficient water pressure.

Automation and Control Solutions

In Canada:

Environmental Control Products

Honeywell Limited-Limitee

1985 douglas Drive North

35 Dynamic Drive

Golden Valley, MN 55422-3992

Toronto, ON M1V 4Z9

U.S.A.

Canada

Printed in Canada