Information brochure in section 1.4 of Annex II of Directive 89/686/EEC Personal chemical resistant protective gloves Cat. III

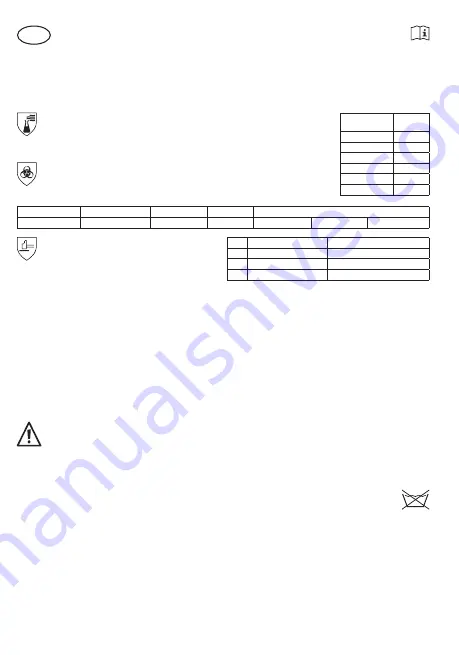

EN 388, Mechanical risks

1st digit Abrasion resistance

(min. 0; max. 4)

2nd digit Cut resistance

(min. 0; max. 5)

3rd digit Tear strength resistance (min. 0; max. 4)

4th digit Puncture resistance

(min. 0; max. 4)

Article

Name

Size

EN 388

classification letter (KB) / Protection index

890

Vitoject®

8, 9, 10, 11

3101

D/4

F/6

G/4

Penetration

time in min.

Protection

index

> 10

1

> 30

2

> 60

3

> 120

4

> 240

5

> 480

6

The CE marking on this glove means that it meets the essential requirements for

in the European Directive EEC 89/686 concerning Individual Protection

Equipment (IPE): Harmlessness-Comfort-Dexterity-Sturdiness.

Protective Gloves conform to the EN 420. Approved to EN 374 and EN 388

according to Article 10 of Directive 89/686/EEC: IFA, Alte Heerstraße 111,

EN 374, Full-protection protective gloves against chemicals

The protective index refers to the permeation time determined during uninterrupted contact with the test chemical

under stable laboratory conditions. EN 374-3 =

Permeation

. A glove is resistant to chemicals, when a protection

index is achieved at least Level 2 in three of the chemicals listed below. The chemicals which have passed the test are

marked on the gloves with the letters A-L. (KB=classification letters.)

EN 374, Protection against bacteriological contamination

KCL chemical protective gloves have been penetration-tested to the highest performance level (3) set out in EN 374-2.

This quality limit equates to an AQL < 0.65.

D-53757 St. Augustin, Identification number: 0121Surveillance after 11 B of

Directive 89/686/EEC, chemical risks according to EN 374: same location as type test.

The identification number for testing and certification centre 0121 for EC type

testing and monitoring of quality assurance measures relates solely to the

content of EN 374-1: 2003 and the PPE Directive 89/686/EEC.

GB

WARNING !

Resistance to the chemicals listed was determined under laboratory

conditions and may be adversely affected by changes to physical

properties such as temperature, abrasion, stretching, etc. When

using highly corrosive chemicals, degradation is the most important

factor in the choice of protective gloves.

These protective gloves provide no protection against extreme cold

(< - 5 °C), heat (> 50 °C), electricity.

Do not use in the vicinity of moving machine parts. Risk of being

drawn into the machine.

Unusable when the gloves are cracked, porous and stiff.

Safety glove not approved for food contact.

Allergy Notice:

All gloves may contain traces of

Mercaptobenzoicthiazole.

Use:

The protective gloves you wear must be of the correct size. Note

that using undergloves may result in some usage restrictions. Check

the protective gloves for damage before you use them. Damaged

protective gloves must not be used under any circumstances.Prevent

the penetration of pollutants over the edge of the glove. Prevent

carryover of contaminants located on the glove and the cross-

contamination when removing gloves.

Cleaning:

The specified gloves are not washable.

Expiry date: With proper storage, no reduction in performance levels

within 36 months.

Storage/Transport:

Flat, dry, dark, with no additional weight load

in its original packaging, at a temperature of 5 °C - 25 °C. Protect from

sunlight and ozone.

Disposal:

If not contaminated with chemicals, gloves can be

disposed of in the household waste. If the gloves have been exposed

to chemicals, follow the disposal instructions of the manufacturer of

the chemicals.

For further information please contact.

KB Chemical

CAS no.

D

Dichloromethane

75-09-2

F

Toluen

108-88-3

G

Diethylamine

109-89-7

Summary of Contents for Vitoject 890

Page 4: ......

Page 5: ......

Page 6: ......

Page 34: ...www honeywellsafety com ...

Page 35: ......