INSTALLATION INSTRUCTIONS

69-2013

VR8245 and VR8345 Universal

Electronic Ignition Gas Controls

APPLICATION

The universal electronic ignition gas controls are used in

gas-fired appliances with capacities up to 300 cu ft/hour

at 1 inch wc pressure drop [8.5 cu m/hour at 0.25 kPa] for

natural gas. These gas controls will operate with a direct

spark (DSI), hot surface (HSI) or intermittent pilot ignition.

The control includes a manual valve, two automatic

operators, a pressure regulator, pilot adjustment, pilot

plug, conduit cover and ignition adapter. Refer to the

following list for the specifications.

SPECIFICATIONS

AMBIENT TEMPERATURE RANGE:

-40° to 175°F

[-40° to 79°C].

BODY PATTERN:

Straight-through.

IGNITION ADAPTER:

Configures device to operate with

direct spark or hot surface ignition.

ELECTRICAL RATINGS:

Voltage and Frequency: 24 Vac, 60 Hz.

Current Draw: See Table 3.

CAPACITY:

See Table 1.

a

Capacity based on 1000 Btu/cu ft, 0.64 specific gravity natural gas at 1 in. wc pressure drop [37.3 MJ/cu m, 0.64 spe-

cific gravity natural gas at 0.25 kPa pressure drop].

Use conversion factors in Table 2 to convert capacities

for other gases.

APPROVALS:

American Gas Association Design Certificate:

L2025007.

Canadian Gas Association Design Certificate:

L2025007.

PIPE ADAPTERS:

Includes two 3/4 to 1/2 inch NPT

bushings and one 1/2 to 3/8 inch NPT bushing.

CROSS REFERENCE:

See Table 4 for cross reference

information.

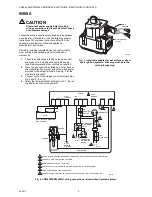

INSTALLATION

WHEN INSTALLING THIS PRODUCT…

1.

Read these instructions carefully. Failure to follow

them could damage the product or cause a hazard-

ous condition.

2.

Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3.

The installer must be a trained, experienced ser-

vice technician.

4.

After installation is complete, use these instructions

to check out product operation.

Table 1. Gas Capacity.

Size (Inlet x Outlet)

Capacity (at 1 in. wc

pressure drop)

a

Minimum Regulated

Capacity

Maximum Regulated

Capacity

3/4 x 3/4

300 cu ft/hour

[8.5 cu m/hour]

30 cu ft/hour

[0.8 cu m/hour]

415 cu ft/hour

[11.8 cu m/hour]

1/2 x 1/2

150 cu ft/hour

[4.25 cu m/hour]

20 cu ft/hour

[0.6 cu m/hour]

200 cu ft/hour

[5.7 cu m/hour]

Table 2. Gas Capacity Conversion Factors.

Gas

Specific Gravity

Multiply Listed

Capacity By

Manufactured

0.60

0.516

Mixed

0.70

0.765

Propane

1.53

1.62