VR8245 AND VR8345 UNIVERSAL ELECTRONIC IGNITION GAS CONTROLS

9

69-2013

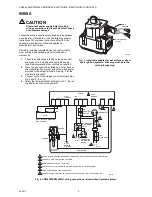

Check And Adjust Gas Input to Main

Burner

CAUTION

Fire or explosion hazard.

1. Do not exceed the input rating stamped on the

appliance nameplate, or manufacturer

recommended burner orifice pressure for the

size orifice(s) used. Make certain the primary

air supply to the main burner is properly

adjusted for complete combustion (refer to the

appliance manufacturer instructions).

2. WHEN CHECKING GAS INPUT BY

CLOCKING THE GAS METER:

• Make sure that the only gas flow through the

meter is that of the appliance being checked.

• Make certain that other appliances are turned

off with pilot burners extinguished (or deduct

that gas consumption from the meter

reading).

• Convert the flow rate to Btuh as described in

Gas Controls Handbook, form 70-2602, and

compare to the Btuh input rating on the

appliance nameplate.

3. WHEN CHECKING GAS INPUT WITH A

MANOMETER (PRESSURE GAUGE):

• To connect the manometer, be sure the gas

control knob is in the OFF position before

removing the outlet pressure tap plug.

• When removing the manometer, turn the gas

control knob back to OFF and replace the

outlet pressure tap plug.

• Shut off the gas supply at the appliance

service valve, or at the gas tank for LP gas,

before removing the outlet pressure tap plug

and before disconnecting the manometer and

replacing the outlet pressure tap plug.

• Perform the Gas Leak Test at the outlet

pressure tap plug.

Standard-Opening Pressure Regulator

1.

The gas control outlet pressure should match the

manifold pressure listed on the appliance name-

plate.

2.

With the main burner operating, check the gas con-

trol flow rate by using the meter clocking method or

check the gas pressure using a manometer con-

nected to the gas control outlet pressure tap. See

Fig. 3.

3.

If necessary, adjust the pressure regulator to match

the appliance rating. Refer to Table 6 for the factory

set nominal outlet pressures and adjustment setting

ranges.

a. Remove the pressure regulator adjustment cap

screw.

b. Using a screwdriver, turn the inner adjustment

screw clockwise

to increase or counter-

clockwise

to decrease the main burner gas

pressure.

c. Always replace the cap screw and tighten firmly

to safeguard proper operation.

4.

If the desired outlet gas pressure or gas flow rate

cannot be achieved by adjusting the gas control,

check the gas control inlet pressure by using a

manometer at the inlet pressure tap. If the inlet

pressure is in the normal range (refer to Table 6 and

7), replace the gas control. Otherwise, take the nec-

essary steps to provide proper gas pressure to the

gas control.

Standard and Slow-Opening (H and M) Models

1.

Carefully check the main burner lightoff. Make sure

that the main burner lights smoothly and that all

ports remain lit.

2.

Check the full rate manifold pressure listed on the

appliance nameplate. Gas control full rate outlet

pressure should match this rating.

3.

With main burner operating, check the control flow

rate using the meter clocking method or check pres-

sure using a manometer connected to the outlet

pressure tap on the control. See Fig. 3.

4.

If necessary, adjust the pressure regulator to match

the appliance rating. See Table 6 and 7 for factory-

set nominal outlet pressure and adjustment range.

a. Remove the pressure regulator adjustment cap

screw.

b. Using a screwdriver, turn the inner adjustment

screw (Fig. 3) clockwise

to increase or

counterclockwise

to decrease the gas pres-

sure to the burner.

c. Always replace the cap screw and tighten firmly

to prevent gas leakage.

5.

If the desired outlet pressure or flow rate cannot be

achieved by adjusting the gas control, check the

gas control inlet pressure using a manometer at the

inlet pressure tap of the gas control. If the inlet pres-

sure is in the nominal range (see Table 6 and 7),

replace the gas control. Otherwise, take the neces-

sary steps to provide proper gas pressure to the

control.

Two-Stage (Q) Models

Two-stage models require that you check and adjust both

high and low pressure regulator settings. Two-stage

appliance operating sequences vary. Consult the

appliance manufacturer instructions for the specific

operating sequence and regulator adjustment procedure

for the appliance in which the control is installed.

1.

Set appliance to operate on high.

2.

Carefully check the main burner lightoff. Make sure

that the main burner lights smoothly and that all

ports remain lit.

3.

Check the full rate (high) manifold pressure listed

on the appliance nameplate for high pressure. The

gas control full rate outlet pressure should match

this rating.

4.

With main burner operating, check the gas control

flow rate using the meter clocking method or check

pressure using a manometer connected to the out-

let pressure tap on the gas control. See Fig. 3.

5.

If necessary, adjust the high pressure regulator to

match the appliance rating. See Table 6 and 7 for

factory-set nominal outlet pressure and adjustment

range.

a. Remove the pressure regulator adjustment cap

(Fig. 3).

b. Using a screwdriver, turn the inner adjustment

screw for HI pressure clockwise

to increase

or counterclockwise

to decrease the gas

pressure to the burner.

6.

After high pressure has been checked, check low

pressure regulation. Two-stage appliance operat-

ing sequences vary. Consult the appliance manu-

facturers instructions for the specific operating

sequence and regulator adjustment procedure for

the appliance in which the control is installed and

for instructions on how to prevent the control from

moving to high stage while checking the low pres-

sure regulator setting.