69-0624—2

6

TABLE 7—MAXIMUM LENGTH OF SUPPLEMENTARY LIMIT LEADWIRES

WHEN USING Q309A THERMOCOUPLE.

Maximum Leadwire Length x 2 (Wires)

Thermocouple Length

Awg No. 14

Awg No. 16

Awg No. 18

Inches

Meters

Inches

Meters

Inches

Meters

Inches

Meters

12

0.3

47

1.2

30

0.8

18

0.5

18

0.5

41

1.0

26

0.7

16

0.4

24

0.6

35

0.9

22

0.6

14

0.4

30

0.8

29

0.8

18

0.5

11

0.3

36

0.9

23

0.6

15

0.4

9

0.2

40

1.0

19

0.5

12

0.3

7

0.2

48

1.2

11

0.3

7

0.2

60

1.5

DO NOT USE.

Start-up and Checkout

WARNING

FIRE OR EXPLOSION HAZARD CAN

CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH

1. Do not force the gas control knob. Use only your

hand to push down the reset button or turn the

gas control knob. Never use any tools.

2. If the gas control knob or reset button will not

operate by hand, or if the reset button stays

depressed after it is released, to replace the gas

control call a qualified service technician.

GAS CONTROL KNOB SETTINGS

The gas control knob has three settings:

OFF: Prevents pilot and main burner gas flow.

PILOT: Permits pilot gas flow only. Gas control knob

must be held depressed or the thermocouple must be

heated sufficiently to hold the safety control valve

open.

ON: Permits main burner and pilot gas flow. Gas control

and thermostat control main burner gas flow.

NOTE: Gas controls are shipped with the gas control knob in

the ON position.

PERFORM GAS LEAK TEST

WARNING

FIRE OR EXPLOSION HAZARD CAN

CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH

Check for gas leaks with rich soap and water

solution any time work is done on a gas control.

GAS LEAK TEST

1. Paint all pipe connections upstream of the gas control

with a rich soap and water solution. Bubbles indicate a gas

leak.

2. If a gas leak is detected, tighten the pipe connection.

CAUTION

Stand clear while lighting main burner to prevent

injury caused from hidden gas leaks that could

cause flashback in the appliance vestibule.

3. Light the main burner.

4. With the main burner in operation, paint all pipe joints

(including adapters) and gas control inlet and outlet with rich

soap and water solution.

5. If another gas leak is detected, tighten adapter screws,

joints, and pipe connections.

6. If gas leak cannot be stopped, turn the gas control knob

clockwise to off.

7. Replace the leaking part.

8. Perform the gas leak test.

LIGHT THE PILOT BURNER FLAME

1. Turn the gas control knob clockwise to OFF.

Wait five minutes to dissipate any unburned gas. Sniff

around the appliance near the floor. Do not relight the pilot

flame if you smell gas.

2. Turn the gas control knob counterclockwise to

PILOT. Push down and hold the gas control knob while

lighting the pilot flame.

3. Hold the gas control knob down about one minute,

then release.

• If the pilot flame goes out, turn the gas control knob

clockwise to OFF and repeat steps one through

three.

• If pilot flame remains lit, turn the gas control knob

counterclockwise to ON.

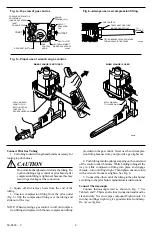

ADJUST THE PILOT BURNER FLAME

The pilot flame should envelop 3/8 to 1 /2 in. [10 to 13 mm]

of the thermocouple tip. Refer to Fig. 10. To adjust the pilot

flame:

1. Remove the pilot adjustment cover screw. Refer to

Fig. 5.

2. Turn the inner adjustment screw clockwise , to

decrease or counterclockwise to increase the pilot

flame.

3. Be sure to replace the cover screw after adjustment

and tighten firmly.