9

69-0624—2

Service

WARNING

FIRE OR EXPLOSION HAZARD CAN

CAUSE PROPERTY DAMAGE, SEVERE

INJURY OR DEATH

Do not disassemble the gas control; it contains no

replaceable components. Attempted disassembly

or repair may damage the gas control.

CAUTION

Do not apply a jumper across or short the valve coil

terminals. Doing so can burn out the heat anticipa-

tor in the thermostat.

IMPORTANT: Allow 60 seconds after shutdown before re-

energizing step-opening model to assure lightoff at

step pressure.

IF THE PILOT BURNER FLAME WILL NOT

LIGHT

1. Assure the main gas supply valve is open and the pilot

gas supply line is purged of air.

2. Attempt to light pilot burner flame following proce-

dures in the Lighting the Pilot Burner Flame section. If pilot

burner flame still will not light:

a. Check the pilot gas adjustment screw. If closed, read-

just the pilot flame. Refer to Adjust the Pilot Burner

Flame section.

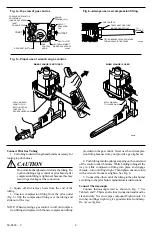

b. Perform the Gas Leak Test at the compression fitting.

If a gas leak is detected, replace the old compression

fitting or tighten the newly installed one. Refer to Fig. 4.

c. Assure that the pilot burner tubing or pilot burner

orifice is not clogged.

IF THE PILOT BURNER FLAME GOES OUT

WHEN THE GAS CONTROL KNOB IS RELEASED

1. Assure the gas control knob is held in at least one

minute to allow the thermocouple time to heat.

2. Check the pilot burner flame adjustment. Refer to

Adjust the Pilot Burner Flame section.

3. Check the wiring between the thermocouple and the

gas control valve operator.

4. Assure thermocouple connection to the power unit is

tightened one-fourth turn beyond finger tight.

5. If pilot burner flame still goes out, measure the open

and closed thermocouple output voltage. Compare it to the

acceptable range charts in the thermocouple specifications

or in the Gas Controls Handbook. Replace the thermocouple

if voltages are outside the acceptable range.

6. Check the power unit resistance. If above 11 ohms,

replace the gas control.

IF THE MAIN BURNER WILL NOT COME ON

WITH A CALL FOR HEAT

1. Be sure the gas control knob is in the ON position.

2. Adjust the thermostat several degrees above room

temperature.

3. Use an ac voltmeter to measure the voltage across

terminals TH and TR or MV/PV and MV. If:

a. No voltage is present, check the control circuit for

proper operation.

b. 24 Vac is present, but first operator did not click open,

check for excessive inlet gas pressure. If inlet gas

pressure is correct, replace the gas control.

4. Measure the open and closed thermocouple output

voltages and compare to the acceptable range charts in the

thermocouple specifications or in the Gas Controls Hand-

book. Replace the thermocouple if voltages are outside the

acceptable range.

5. Measure the open and closed thermocouple output

voltages and compare to the acceptable range charts in the

thermocouple specifications or in the Gas Controls Hand-

book. Replace the thermocouple if voltages are outside the

acceptable range.

IF THE MAIN BURNER IS OVERFIRING

Adjust the gas control pressure regulator to the correct

pressure. If the regulator cannot be adjusted and supply the

pressure is in the normal range, replace the gas control.

INSTRUCTIONS TO THE HOMEOWNER

CAUTION

FIRE OR EXPLOSION HAZARD CAN

CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH

Follow these warnings exactly:

1. Pilot burner flame must be lit manually. Follow

these instructions exactly.

2. Before lighting pilot burner flame, smell around

the appliance for gas. Be sure to smell next to

floor because LP gas is heavier than air.

3. IF YOU SMELL GAS:

• Turn off the gas supply at the appliance

service valve. On LP gas systems, turn off

the gas supply at the gas tank.

• Do not light any appliances in the house.

• Do not touch electrical switches or use the

phone.

• Leave the building and use a neighbor’s

phone to call your gas supplier.

• If you cannot reach your gas supplier, call

the fire department.

4. Do not force the gas control knob. Use only

your hand to push down or turn the gas control

knob. Never use any tools. If the gas control

knob will not operate by hand, the gas control

should be replaced by a qualified service tech-

nician. Force or attempted repair can result in a

fire or explosion.

5. Replace the gas control in case of any physical

damage, tampering, bent terminals, missing or

broken parts, stripped threads, evidence of ex-

posure to heat or if flooded by water.