achieved by adjusting the gas control, check gas control

inlet pressure using a manometer at inlet pressure tap. If

inlet pressure is in the nominal range (refer to Table 5),

replace gas control. Otherwise, take the necessary steps

to provide proper gas pressure to the control.

VS820C,P; VS821C (Step-Opening Pressure Regulator)

1. Check the full rate manifold pressure listed on the

appliance nameplate. Gas control full rate outlet pressure

should match this rating.

2. With main burner operating, check gas control outlet

flow rate using the meter clocking method or outlet pres-

sure using a manometer connected to the outlet pressure

tap on the control. Refer to Fig. 3 or 4.

3. If necessary, adjust pressure regulator to match ap-

pliance rating. Refer to Table 5 for factory set nominal

outlet pressure and adjustment range.

a. Remove pressure regulator adjustment cap

screw.

b. Using screwdriver, turn inner adjustment screw

clockwise

to increase or counterclockwise

to decrease gas pressure to burner.

c. Always replace cap screw and tighten firmly to

ensure system functions properly.

4. If desired outlet pressure or flow rate cannot be

achieved by adjusting the gas control, check gas control

inlet pressure using a manometer upstream of the gas

control. If inlet pressure is in the nominal range (refer to

Table 5), replace gas control. Otherwise, take the neces-

sary steps to provide proper gas pressure to the control.

5. Carefully check burner lightoff at step pressure. Make

sure burner lights smoothly and without flashback to ori-

fice. Make sure all ports remain lit. Cycle burner several

times, allowing at least 30 sec. between cycles for regula-

tor to resume step function. Repeat after allowing burner

to cool. Readjust full rate outlet pressure if necessary to

improve lightoff characteristics.

IMPORTANT

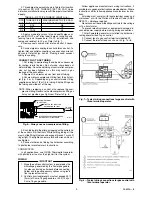

The V5308 on the VS820D is not field adjustable.

The HI or LOW flame setting is selected by position-

ing the white knob on the regulator. Refer to Fig. 10.

Fig. 10—HI and LOW settings for VS820D.

1. Check the LOW flame setting listed on the appliance

nameplate. Gas control LOW flame setting should match

this rating.

2. With main burner operating, check gas control outlet

flow rate using the meter clocking method or outlet pressure

using a manometer connected to the outlet pressure tap on

the control. Refer to Fig. 3 or 4.

3. Check gas control inlet pressure using a manometer

at inlet pressure tap. If inlet pressure is in the nominal range

(refer to Table 5), replace gas control. Otherwise, take the

necessary steps to provide proper gas pressure to the

control.

4. Carefully check burner lightoff at LOW flame setting.

Make sure burner lights smoothly and without flashback to

orifice. Make sure all ports remain lit. Cycle several times

and repeat after allowing burner to cool.

5. Check the HI flame setting listed on the appliance

nameplate and repeat the above steps for the HI flame

setting.

TABLE 5—PRESSURE REGULATOR SPECIFICATION PRESSURES IN in. wc.

FACTORY SET

NOMINAL OUTLET

SETTING

TYPE

NOMINAL INLET

PRESSURE

RANGE

MODEL

OF GAS PRESSURE RANGE

STEP

FULL RATE

STEP

FULL RATE

VS820A,H,V;

NAT

5.0-7.0

—

3.5

—

3-5

VS821A

LP

12.0-14.0

—

11.0

—

8-12

VS820C,P

NAT

5.0-7.0

0.9

3.5

None

3-5

VS821C

LP

12.0-14.0

2.2

11.0

None

8-12

VS820D

NAT

5.0-7.0

—

1.0 Low

Nonadjustable

3.5 Hi

LP

12.0-14.0

—

2.75 Low

Nonadjustable

11.0 Hi

TABLE 5A—PRESSURE REGULATOR SPECIFICATION PRESSURES IN kPa.

FACTORY SET

NOMINAL OUTLET

SETTING

TYPE

NOMINAL INLET

PRESSURE

RANGE

MODEL

OF GAS PRESSURE RANGE

STEP

FULL RATE STEP

FULL RATE

VS820A,H,V;

NAT

1.2-1.7

—

0.9

—

0.7-1.2

VS821A

LP

2.9-3.9

—

2.7

—

2-3

VS820C

NAT

1.2-1.7

0.2

0.9

None

0.7-1.2

VS821C

LP

2.9-3.9

0.5

2.7

None

2-3

VS820D

NAT

1.2-1.7

—

0.2 Low

Nonadjustable

0.9 Hi

LP

2.9-3.9

—

0.7 Low

Nonadjustable

2.7 Hi

VS820D (Hi-Low Flame Pressure Regulator)

5

95-6994—8

H

I - P U S

-

H

P U

O

L

L L

KNOB MARKINGS

(TOP VIEW)

LOW FLAME

(PULL KNOB UP)

HI FLAME

(PUSH KNOB DOWN)

M1145

W

Summary of Contents for VS820A

Page 8: ......