PRODUCT DATA

Put Bar Code Here

95C-10883-03

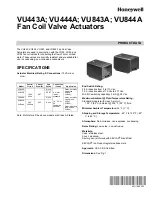

VU443A; VU444A; VU843A; VU844A

Fan Coil Valve Actuators

The VU443, VU444, VU843, and VU844 Fan Coil Valve

Actuators are used in conjunction with the VU52, VU53, and

VU54 fan coil valves for controlling the flow of hot or chilled

water. These valves are humidity resistant and are suitable for

use in condensing, non-corrosive environments.

SPECIFICATIONS

Actuator Electrical Rating & Connections:

10 VA maxi-

mum.

Note: Motors for all the above models are Class A, Plated.

End Switch Rating:

2.2 A inductive from 5 to 110 Vac.

1.0 A inductive above 110 Vac to 277 Vac.

Min. DC switching capability: 5 mA @ 24 Vdc.

Maximum Ambient @ Fluid Temperature Rating:

Standard models (with class A motor):

125° F (52° C) ambient @ 200° F (93° C) fluid.

Minimum Ambient Temperature:

34° F (1° C).

Shipping and Storage Temperature:

-40° F to 150° F (-40°

C to 65° C).

Atmosphere:

Non-corrosive, non-explosive, condensing.

Noise Rating:

Low noise - non-obtrusive.

Materials:

Case: stainless steel.

Cover: aluminum.

Sector gear: reinforced with KEVLAR

®

brand fiber.

KEVLAR

®

is a Dupont registered trademark.

Approvals:

CSA C/US Certified.

Dimensions:

See Fig. 1.

Model

Control

CIrcuit

Current

Draw (A)

End

Switch

Connection

/Leads

Application

VU443A

120V,

60Hz

0.07

None

6” motor

leads

standard.

18”, 36”, or

96”

Leadwires

optional.

2-way, normally

open (use

VU444,

VU844);

VU443E

SPST

VU444A

None

2-way, normally

closed (use

VU443,

VU843);

VU843A

VU844A

24V,

50-60Hz

0.32

None

3-way, diverting

(use VU444,

VU844).