® U.S. Registered Trademark

Copyright © 2011 Honeywell Inc.

▪

All Rights Reserved

EN1B-0250GE51 R0111B

Excel 10

W7752D,E,F,G FAN COIL UNIT CONTROLLERS

HONEYWELL EXCEL 5000 OPEN SYSTEM

INSTALLATION INSTRUCTIONS

The Excel 10 Fan Coil Unit (FCU) Controller is available in the

following four models:

W7752D2007 (230 Vac, with electric reheat relay),

W7752E2004 (230 Vac, without electric reheat relay),

W7752F2002 (115 Vac, with electric reheat relay),

W7752G2000 (115 Vac, without electric reheat relay).

All have identical housings and mounting procedures.

IMPORTANT

It is recommended that devices be kept at room

temperature for at least 24 hours before applying

power to allow any condensation resulting from low

shipping/storage temperatures to evaporate.

This device must be installed in a UL-listed

enclosure offering adequate space to maintain the

segregation of line voltage field wiring and Class 2

field wiring (US requirement only).

INSTALLATION

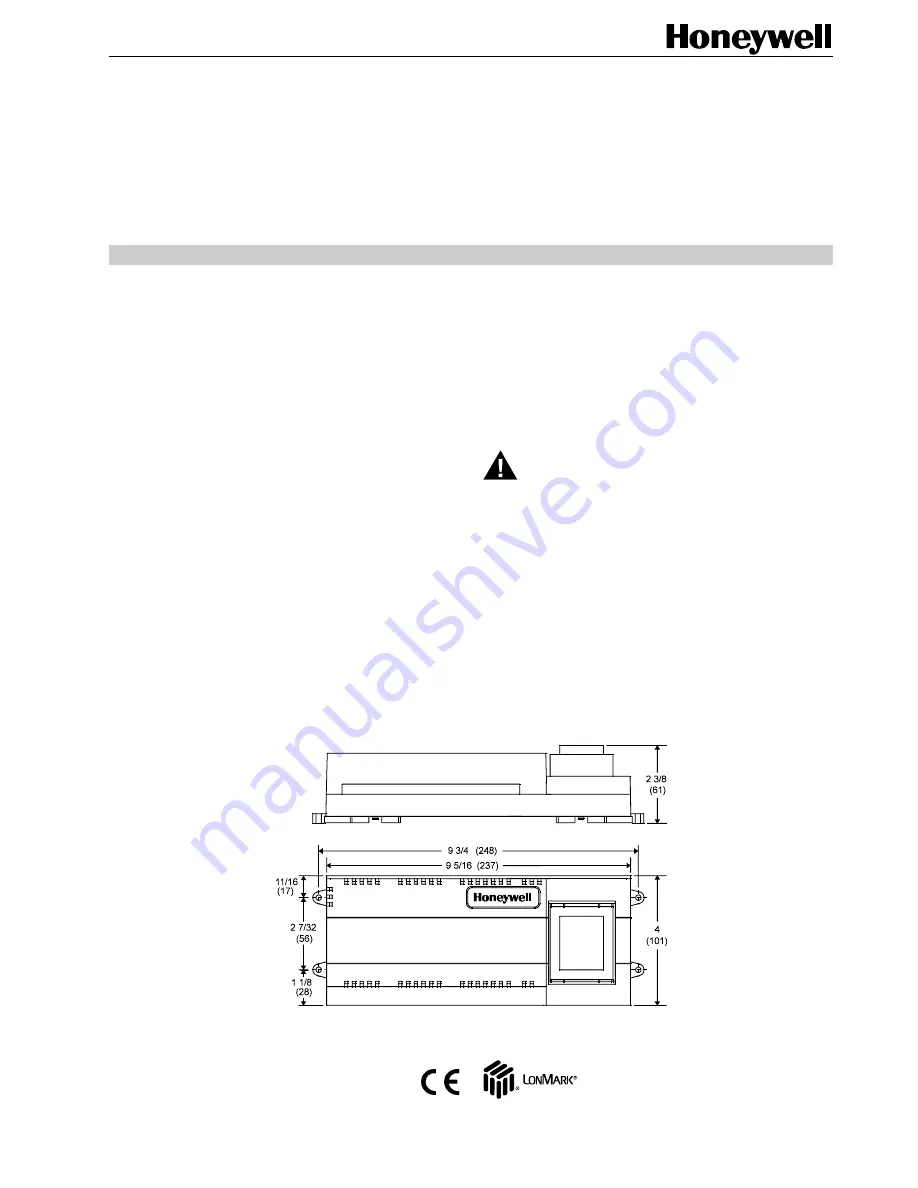

Mount the Fan Coil Unit controllers in locations that allow

clearance for wiring. The controllers can be mounted on a

panel with screws or by snapping onto standard EN 50 022

DIN rail, 1-3/8 by 9/32 in. (35 mm by 7.5 mm). See Fig. 1 for

mounting dimensions. See Fig. 2 for DIN rail mounting. The

type and length of screw required for screw mounting

depends upon the panel material used to mount the con-

troller.

The controller can be mounted either vertically or horizontally.

However, if thermal actuators are connected to the controller

outputs, it is recommended that the controller be mounted so

that the transformer is not located beneath the electronics.

WARNING

ELECTRICAL SHOCK HAZARD.

Source power at terminal block can cause personal

injury or death. W7752 FCU Controllers must be

mounted inside their respective fan coil unit boxes to

prevent access by unauthorized personnel.

To reduce the risk of fire or electric shock, install in a

controlled environment relatively free of contaminants.

Wiring

All wiring must comply with applicable electrical codes and

ordinances. Refer to job or manufacturers’ drawings for

details.

Fig. 1. Excel 10 Fan Coil Unit Controller outside and mounting dimensions in in. (mm)

BEFORE INSTALLATION