W8835A ENVIRAZONE PANEL

68-0258ES-1

10

Wire the reversing valve to the O/B equipment terminal. DIP

switch 9 configures this terminal to operate as an O (cool) or

B (heat) changeover terminal.

Thermostat Operation

Conventional Equipment

Conventional equipment of up to three stages of heat and two

stages of cool can be controlled by the W8835. The panel is

configured to control equipment stages using DIP switches 1,2

and 7.

Heat Pump Equipment

Heat pump equipment with up to two heat-cool compressor

stages and auxiliary heat can be controlled by the W8835. The

panel is configured to control equipment stages using DIP

switches 1,2, and 7.

Emergency Heat Control

Emergency heat is defined as using an auxiliary heat source

without using the heat pump. The thermostat system switch is

set to Em Heat to engage this function. When active, any zone

calling for heat uses Emergency Heat, not the compressor, on

a call for heat.

Manual and Automatic Changeover Operation

Each of the T8635L Thermostats can be set for manual or

automatic changeover. If one or more thermostats call for

cooling while one or more thermostats call for heating, the

panel attempts to satisfy the greatest demand first.

Then, based on the relative demand for heating and cooling,

the panel intelligently switches between heating and cooling.

The system attempts to satisfy both the heating and cooling

demands, and does not lock out one demand in favor of the

other.

Zone of Greatest Demand

The panel designates the zone that has the highest

requirement for heat or cool as the Zone of Greatest Demand.

It is then the only zone that can energize the equipment; all

other zones receive only damper control.

The equipment then cycles more regularly than other zone

control systems because the zone that requires conditioning

the most energizes the equipment and the other zones close

as they become satisfied. Also, more dampers are simul-

taneously open more often on calls for equipment, resulting in

less bypass damper usage and more efficient equipment

usage. All zones are satisfied; however, because if, at any

moment, another zone has a higher demand, it becomes the

Zone of Greatest Demand.

Discovery

Discovery is an automatic system configuration program where

the panel configures itself to operate with controls connected to

the EnviraCom bus. The panel enters Discovery when the

Discovery button on the panel is pressed.

Rebooting Microprocessor

To reset the microprocessor, press and release the Boot

button. The system reboots and enters the Purge mode.

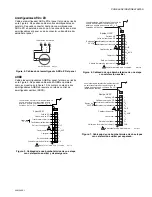

EnviraCom Furnace

For furnaces with EnviraCom communications built in,

configure the panel, as shown below. In this case, no

conventional equipment wiring is necessary because the

W8875 uses the 3-wire EnviraCom bus to control the HVAC

equipment.

Humidity, De-humidity and Ventilation Control

The panel can control humidity, de-humidity, and ventilation by

receiving messages from humidity, de-humidity, and ventilation

EnviraCom controls when they become available in the future.

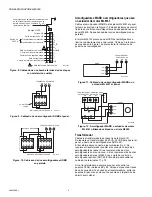

Discharge Air Temperature Sensor DATS

The C7835A1009 Discharge Air Temperature Sensor (not

included) is a supply-duct-mounted temperature sensor probe

used to control capacity and prevent over-heating or coil-icing.

The sensor is wired to the EnviraCom bus using three wires.

When a high or low limit is reached, the panel shuts off the

equipment and keeps the fan operating for a minimum of two

and one-half minutes. After this time, and any applicable

minimum-off times imposed by the thermostat, it re-energizes

the equipment when the discharge air has recovered by ten

degrees. When the high or low limit is exceeded, the Heat (red)

or Cool (green) LED on the DATS flashes.

When the DATS is in a limit condition, the Heat, Cool and

Purge LEDs on the W8835A panel continue to operate as if the

DATS were not turning the equipment off.

The high and low limit is set on the DATS. The high

temperature limit is set from 110 °F to 160°F with a small

screwdriver or using fingers and the low limit is set at 40°F or

48°F degrees with a jumper. The recommended high limit

setting for fossil fuel/ electric systems is 160°F (default factory

setting). For heat pump systems, the recommended setting is

120°F.

The recommended low limit is 40°F for most appliances. If

condensation due to high humidity is a concern, then set the

low limit to 48°F.

Compressor Stages

DIP 7

1 Stage

On

2 Stage

Off

Heat Pump Changeover

DIP 9

O (Cool)

On

B (Heat)

Off

Type of Equipment

DIP 3

Conventional

On

EnviraCom

Off