WT8840 TRADE WATER HEATER CONTROLS

34-00013EF—01

2

PLANNING THE INSTALLATION

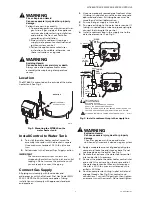

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow these warnings exactly:

1. Plan the installation as outlined below

2. Plan for frequent maintenance as

described in the Maintenance section.

3. Review the following conditions that can

apply to your specific installation and take

the precautionary steps provided.

Frequent Cycling

This control is designed for use on appliances that

typically cycle three to five times a day. In year-round

applications with greater cycling rates of 10,000

cycles annually, the control can wear out more quickly.

Perform a monthly checkout.

Water or Steam Cleaning

If a control gets submerged in water, replace it. If the

appliance is likely to be cleaned with water or steam,

protect (cover) the control and wiring from water or

steam flow. Mount the control high enough above the

bottom of the cabinet so it does not get wet during

normal cleaning procedures.

High Humidity or Dripping Water

Dripping water can cause the control to fail. Never

install an appliance where water can drip on the

control. In addition, high ambient humidity can cause

the control to corrode and fail. If the appliance is in a

humid atmosphere, make sure air circulation around

the control is adequate to prevent condensation. Also,

regularly check out the system.

Corrosive Chemicals

Corrosive chemicals can attack the control, eventually

causing a failure. If chemicals are used for routine

cleaning, avoid contact with the control. Where

chemicals are suspended in air, as in some industrial

or agricultural applications, protect the control with a

cover.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause the

control to malfunction. Where dust or grease can be a

problem, provide covers for the control to limit

contamination.

Heat

Excessively high temperature can damage the control.

Make sure the maximum ambient temperature at the

control does not exceed the rating of the control. If the

appliance operates at very high temperatures, use

insulation, shielding, and air circulation, as necessary,

to protect the control. Proper insulation or shielding

should be provided by the appliance manufacturer.

Verify proper air circulation is maintained when the

appliance is installed.

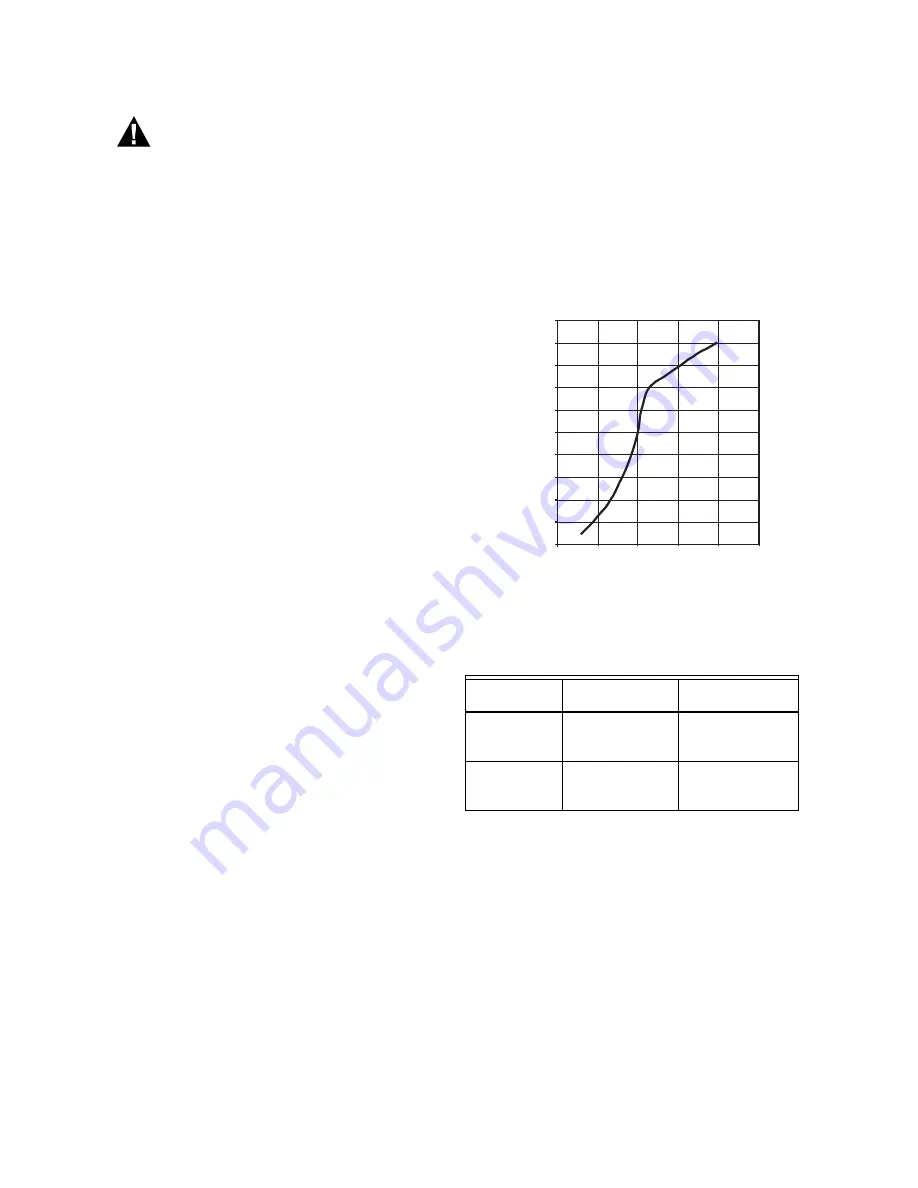

Flow Capacity & Pressure Drop

Fig. 1 shows the typical flow (kBTU/hr) vs pressure

drop (in. w.c.) curve for natural gas and LP gas. Actual

pressure drop depends on the internal configuration

of the valve. Table 1 shows the pressure drop at

various flows for the control.

Fig. 1. Typical capacity curve for WT8840 family

water heater control system.

Table 1. Gas capacity conversion for WT8840.

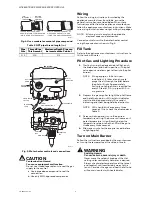

INSTALLATION

When Installing This Product…

1.

Read these instructions carefully. Failure to

follow them could damage the product or cause

a hazardous condition.

2.

Check the ratings given in the instructions and

on the product to make sure the product is

suitable for your application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

Gas Type

Flow (kBTU/hr)

Pressure Drop

(in. w.c.)

NG

30

50

75

1.43

1.47

1.54

LP

30

50

75

0.91

0.94

0.97

M36122

0.8

0.9

1.0

1.1

1.2

1.3

WT8840 CAPACITY DATA

0

10

20

30

40

50

60

70

80

90

100

PRESSURE DROP (IN WC)

FLOW

(KBTU/HR)