HONEYWELL MODEL 700/800 SIGNAL PROCESSOR AND VIEWING HEAD

23

66-2069EP—04

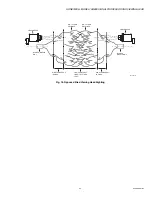

Fig. 14. Viewing Head Mounting Example.

Fig. 15. Viewing Head Mounting Example.

Mounting Examples

Purge air should be provided via the purge air connection to

reduce conducted heat and to keep the sight pipe and viewing

head lens free of dirt and debris. Refer to “Purge Air” on

page 10 for requirements. For electrical isolation reasons, the

purge air line should be installed using and insulating material,

such as a rubber hose, in between the purge air line and the

viewing head. Note that an extension pipe may be required to

locate the viewing head further from the burner front plate to

avoid high temperatures. Additionally, an Ultem replacement

insulating mounting block is available for all models, which is

rated for 320F (160C) continuous service. Also available are

cooling jackets which are used with vortex coolers. The

Honeywell Ultem R-518-13 nipple or R-518-PT13/R-518-

PT13L locking coupler adapter and R-518-CL13-HTG locking

coupler can also be used for heat insulation reasons. Refer to

the Accessories section of this document for accessory part

numbers.

1 (25) NPT NIPPLE TOE

700-1 SWIVEL MOUNT

BURNER FRONT PLATE

M34537A

1/4 (6) NPT PURGE

CONNECTION

S70X VIEWING HEAD

QUICK DISCONNECT

CABLE CONNECTION

(SUPPLIED)

M34538A

1/4 (6) NPT PURGE

CONNECTION

S70X VIEWING HEAD

QUICK DISCONNECT

CABLE CONNECTION

(SUPPLIED)

BURNER FRONT PLATE

OR WINDOWBOX

1/2 (13) NPTM PIPE

FLANGE

(OPTIONAL)