Chapter 2 - Planning

2.7.3

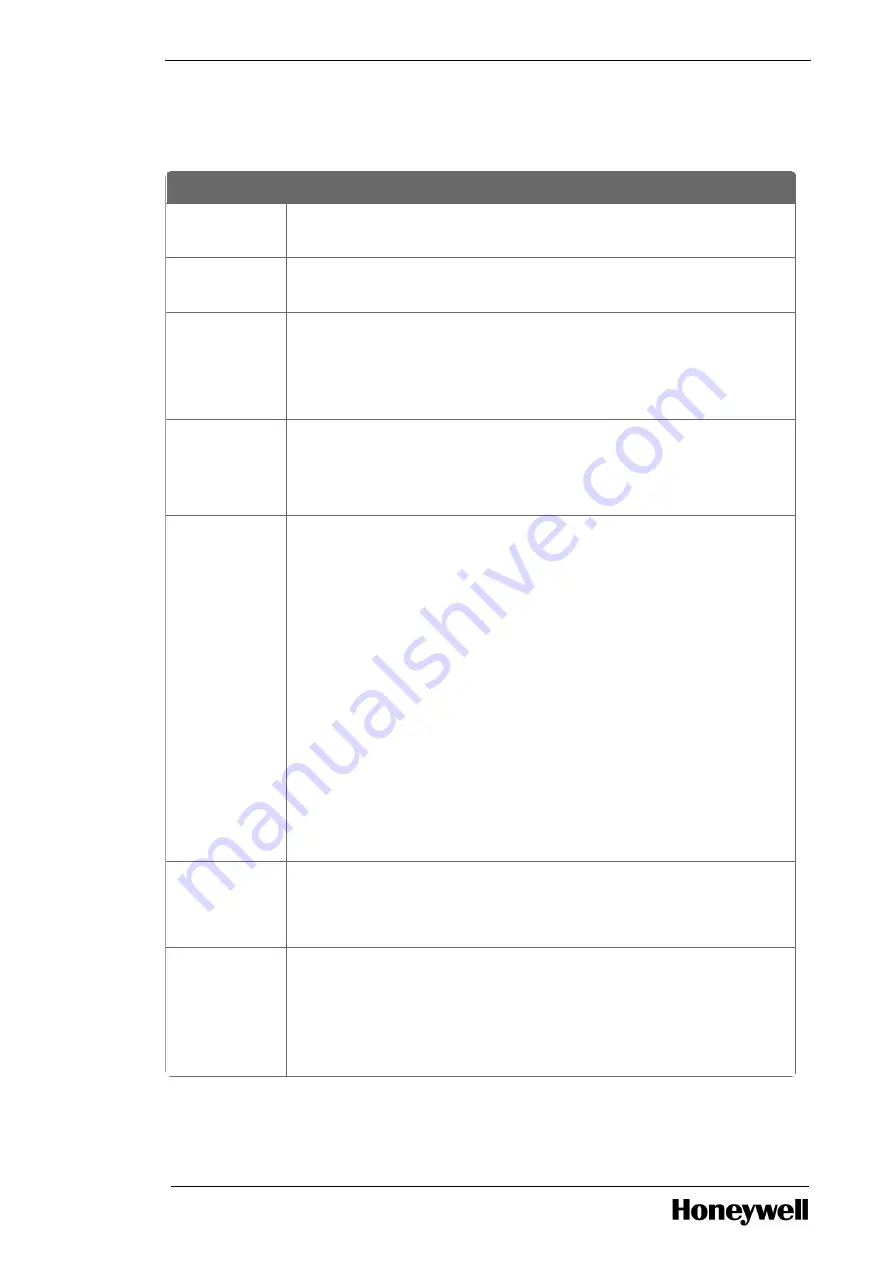

Environmental specifications for cabinets and consoles

The following table lists the allowable operating environmental limitations for cabinets and consoles.

Environmental Specifications

Operating

temperature

5°C to 35 °C (40 °F to 95 °F)

Storage

temperature

-40 °C to 60 °C (-40 °F to 140 °F)

Humidity

Operating: 10% to 85% RH, non-condensing, 35° C maximum wet

bulb

Non-operating: 10% to 90% RH, non-condensing, 35° C maximum wet

bulb

Maximum

altitude

Operating (with Rotational Hard drives): 3,048 m (10,000 feet)

Non-operating: 12,192 m (40,000 feet)

Maximum operating temperature is reduced as altitude increases.

Airborne

contaminant

level

< 300 angstroms/month Copper Reactivity Level

< 3 mm

3

/m

3

parts per billion H

2

S Gas concentration

< 10 mm

3

/m

3

parts per billion S0

2

, S0

3

Gas concentration

< 1 mm

3

/m

3

parts per billion CI

2

Gas concentration

< 50 mm

3

/m

3

parts per billion NO

X

Gas concentration

< 1 mm

3

/m

3

parts per billion HF Gas concentration

< 500 mm

3

/m

3

parts per billion NH

3

Gas concentration

< 2 mm

3

/m

3

parts per billion O

3

Gas concentration

Severity level G1 mild environment limits per ANSI/ISA-S71.04-1985

Standard**

Maximum

vibration

Operating: Operating random: 0.5g (rms), 5-300 Hz, up to 0.0025g²/Hz

Storage: Non-operating random: 2.0g (rms), 5-500 Hz, up to 0.0150

g²/Hz

Site Induced

Shock

For Cabinets: 6g , 11 msec half-sine pulses, 3 positive, 3 negative per

IEC 60068-2-27 10g, 11 msec half-sine pulses, 3 positive, 3 negative

per IEC 60068-2-27

For Consoles: 10g, 11 msec half-sine pulses, 3 positive, 3 negative per

IEC 60068-2-27

*ANSI/ISA-S71.01-1985 Environmental Conditions for Process Measurement and Control Systems:

Temperature and Humidity.

- 25 -