4

Maintenance

Note

Do not use organic solvents (such as acetone or

tetrahydrofuran) as cleaning solutions. Using such chemicals

may damage the body of the electrode or cause a decline in

performance.

To maintain electrode performance, replace the internal

solution approximately every one or two months.

(Refer to “ Preparation ” (page 2).)

Dirt on the responsive glass membrane or liquid junction

by the test solution may cause a decline in electrode

response and sensitivity or measurement error. If the

electrode is very dirty and cannot be washed clean

using pure water (or deionized water), perform cleaning.

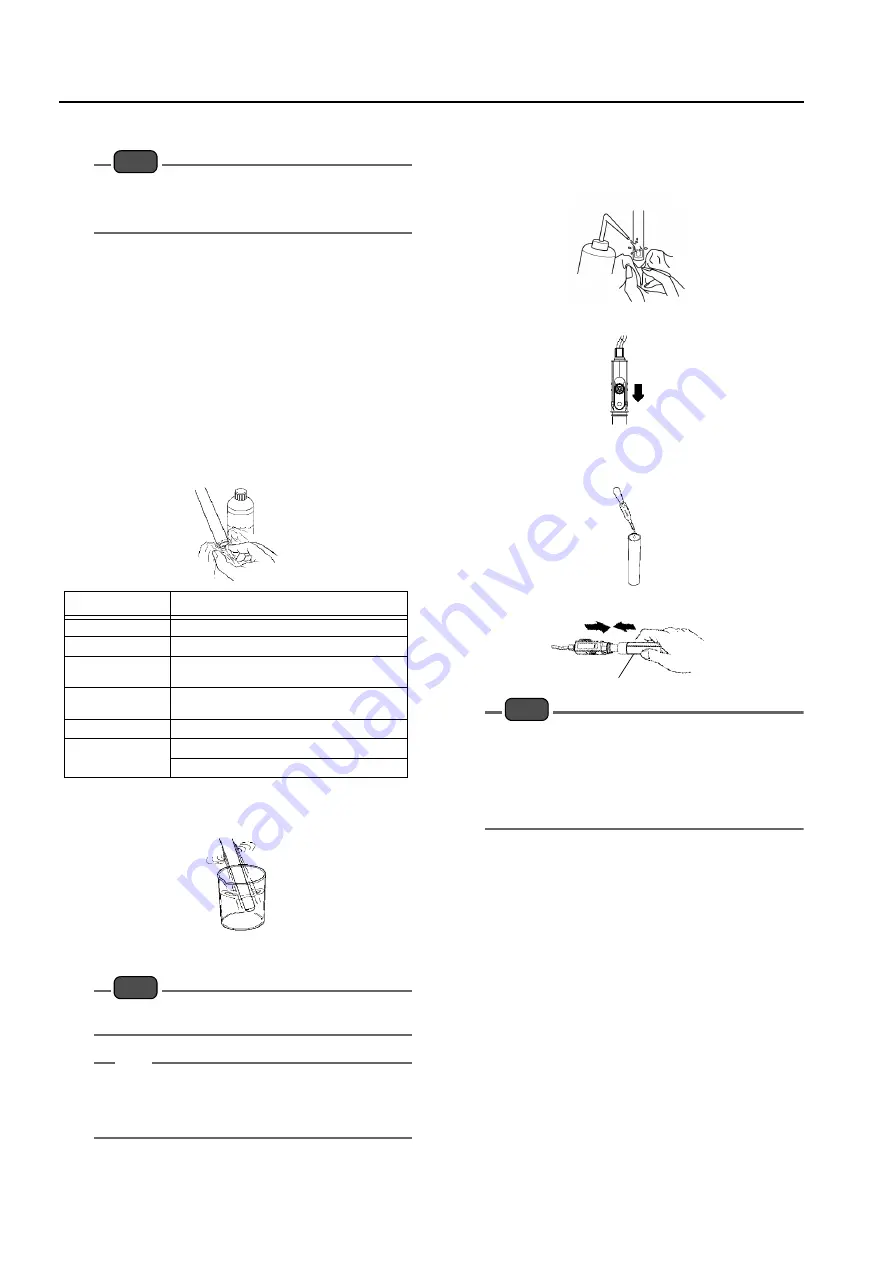

Cleaning of electrode

1. Open the internal solution filler port.

2. Immerse the responsive glass membrane and liquid

junction in the cleaning solution for approximately one

hour until contamination is removed. The responsive

glass membrane can also be cleaned by wiping it with

cotton gauze containing the cleaning solution (exclude

model 230).

3. Rinse the electrode with pure water (or deionized water)

completely.

4. Replace the internal solution.

(Refer to “ Preparation ” (page 2).)

Note

Be sure to perform calibration prior to measurement after

cleaning the electrode.

Tip

Applying pressure on the internal solution until it exudes from

the liquid junction is effective in stabilizing the pH response.

Excessive pressurization will damage the electrode. Stop

applying pressure on the internal solution as soon as it begins

to exude.

Type of dirt

Cleaning solution

General

Diluted neutral cleaning solution

Oil

Alcohol, or diluted neutral cleaning solution

Inorganic substance

Electrode cleaning solution (model 220) or

hydrochloric acid approximately 1 mol/L

Protein

Cleaning solution including protein-removing

enzyme (model 250)

Liquid junction

Electrode cleaning solution (model 220)

Altered of glass,

Slow-response

Electrode cleaning solution (model 220)

Electrode cleaning solution (model 230)

Storage

1. Wash the electrode well with pure water (or deionized

water) to remove sample completely and wipe it with

filter paper or tissue paper.

2. Close the internal solution filler port.

3. Wash the inside of the protective cap with pure water (or

deionized water), then add enough pure water (or

deionized water) to soak the sponge.

4. Attach the protective cap.

Note

Do not dry the responsive glass membrane and liquid

junction. If they are dry, replace the internal solution and

immerse them in pure water (or deionized water) for 24

hours or longer. After these procedures, perform

calibration. If calibration cannot be performed correctly,

replace the electrode.

Avoid storing the electrode in hot and humid locations.

Store the electrode indoors, out of direct sunlight.

For accurate measurement

For accurate measurement, refer to the items below.

Stir the sample solution with stirrer in measurement

(calibration).

In reference to the instruction of the pH meter, perform

temperature compensation manually or automatically.

Temperature of the standard solution and the sample

solution should be the same.

Immerse the responsive glass membrane and the liquid

junction in the sample solution completely. Make sure

that the surface of the internal solution inside the

electrode is higher than the surface of the sample

solution.

Rinse the electrode with the sample solution before

measurement.

Perform calibration before measurement.

If measurement is performed everyday, perform

calibration once or more a day.

Cleaning the electrode with the electrode cleaning

solution (model 230) before measurement enables

quicker measurement of low conductivity water. For the

cleaning method, refer to the instruction manual of the

electrode cleaning solution (model 230).

Protective cap