91

5

T

ro

uble

shootin

g

If an Icon Is Display

ed on the Error Screen /

5-1

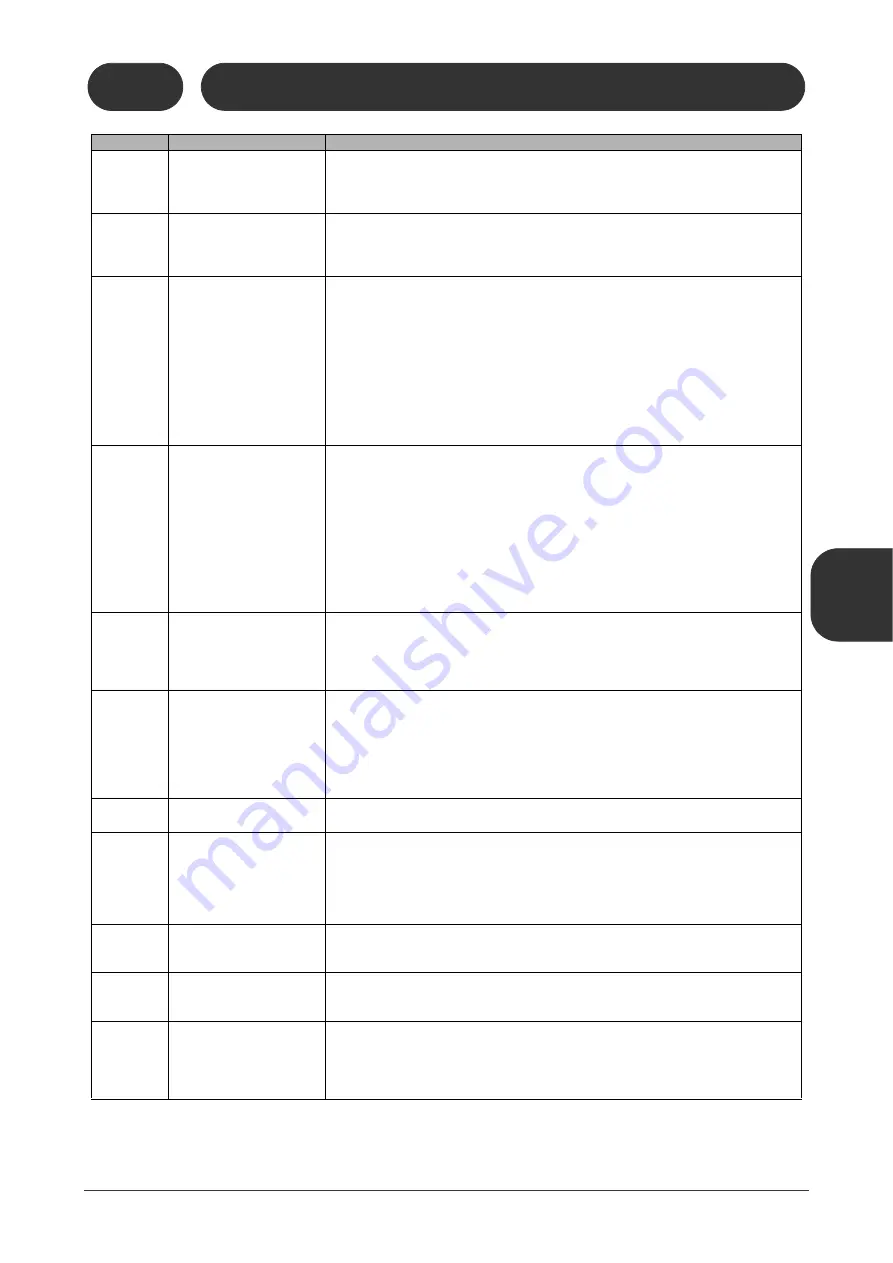

If an Icon Is Displayed on the Error Screen

100 to 199

SPF Section Jam

Cause and Solution

132

No Sheet at Jog Section

There were no sheets in the jog section when the stitching operation was done.

The sheets enter into the jog section before the stopper rises. Therefore, the sheets

may not stop at the correct position. Lower the production speed on the Binding-

Operation screen.

133

Jog Section Top and

Bottom Guide Step-out

There was too much load on the top and bottom guide, or transport pusher, and one

of the parts moved.

Check that only the specified guides and stoppers are attached when you do the

changeover.

134

Stitch Section Front Wire

Feeding Error

There is a problem with the wire feed.

This error is displayed if the preset number of stitching operations has been com-

pleted, or if the wire guide has been detected continuously (wire is tangled), or if the

wire guide has not been detected at all (wire has run out). Check if the wire is strained

from the wire coil to the wire guide.

Check if the wire has run out, or the wire has jammed inside the stitcher head,

Check if a booklet with no stitches has been delivered to the downstream device. If

the problem occurs again although the wire is OK, change the wire feeding detection

setting. (Refer to Section 3-5, step 4.)

On the Administrator Mode screen, set the number of times the machine can miss a

stitch before this error is detected. (Refer to page 31.)

135

Stitch Section Rear Wire

Feeding Error

There is a problem with the wire feed.

This error is displayed if the preset number of stitching operations has been com-

pleted, or if the wire guide has been detected continuously (wire is tangled), or if the

wire guide has not been detected at all (wire has run out.) Check if the wire is strained

from the wire coil to the wire guide.

Check if the wire has run out, or the wire has jammed inside the stitcher head.

Check if a booklet with no stitches has been delivered to the downstream device. If

the problem occurs again although the wire is OK, change the wire feeding detection

setting. (Refer to Section 3-5, step 4.)

On the Administrator Mode screen, set the number of times the machine can miss a

stitch before this error is detected. (Refer to page 31.)

136

Jog Section Transport

Belt Step-out

There was too much load on the transport pusher, and the position of the transport

pusher has changed.

If there are jammed sheets, remove the sheets. If the transport pusher is discon-

nected, attach the transport pusher. Increase the stitch delay time in Binding-Status

Setting Screen. ( Refer to Section 1-3-8.)

137

Jog Section Transport

Error

Some sheets remain in the jog section. Remove the sheets. The possible causes are

following.

- This error may be displayed when operating in high production speed, and the trans-

port belt moves to one side.

- The tail edge of the sheets may stay in the exit of the infeed section, and the sheets

are not transported completely. Adjust the angle of the sheet holder. (Refer to Section

4-2.)

138

Jog Section Delivery

Error

Sheet jams in the transport way between the jog section and the fold section.

Remove the sheets.

150

Fold Section Jog Error

This error may be displayed if the distance between the jog pushers is too tight in

relation to the sheet size. If the sheets are not jogged in the stitch section, increase

the jogging frequency using the Binding-Status Setting screen. (Refer to page 25.)

If the problem occurs again, increase the distance between the fold knife position and

the jog pusher using the Binding-Fine Adjust-Fold Section screen. (Refer to Section

1-3-7.)

151

Fold Section Exit Jam

A booklet is jammed in the exit of the fold section. Remove the jammed booklet.

If a sheet is not jammed, the sensor may be dirty. See Section 6-5-3 and clean the

sensor.

155

Fold Section Jam

A booklet is jammed in the fold section. Remove the jammed booklet. Check if the

buckle gap is too narrow. (Refer to Section 3-3-3.) If a sheet is not jammed, the sen-

sor may be dirty. See Section 6-5-3 and clean the sensor.

156

Delivery Error from Fold

Section

A sheet is jammed in the horizontal transport section (if you are not doing folding) or

in the fold section (if you are doing folding). Remove the sheets. If it is difficult to

remove them, remove the sheet guides first. (Refer to Section 5-2.)

When folding thin booklets, raise the fold knife. Also check if the booklet thickness

has been entered correctly.

Summary of Contents for Bookletmaker FC-200A

Page 84: ...This page is intentionally left blank...

Page 94: ...This page is intentionally left blank...

Page 146: ...This page is intentionally left blank...

Page 202: ...This page is intentionally left blank...

Page 217: ...This page is intentionally left blank...

Page 218: ...Manufacturer Phone 81 75 934 6700 Fax 81 75 934 6708 www horizon co jp...