35

Misfeeding or jamming may occur if one of the feed rollers are stained. This can prevent the sheets from being transported smoothly.

Frequency: Once every 3 months

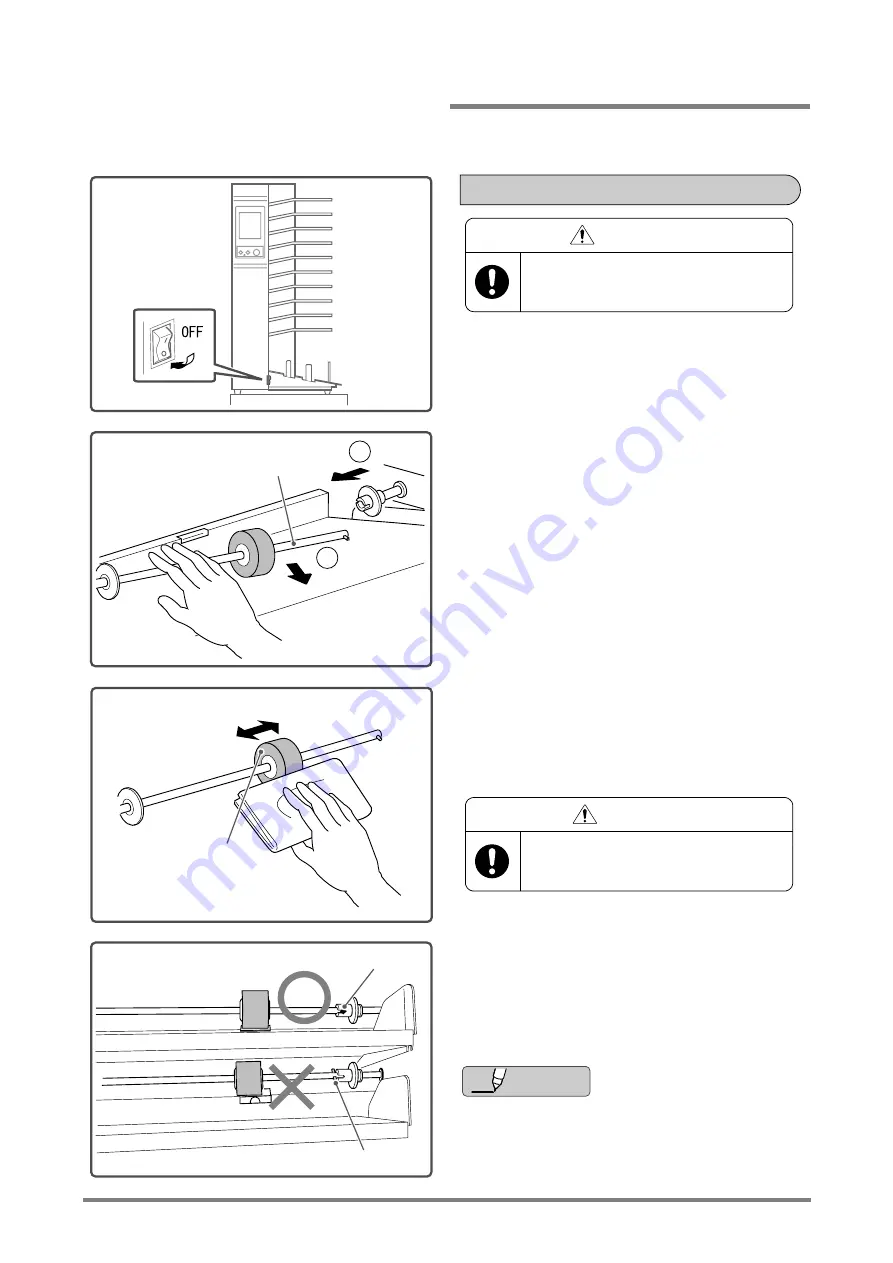

Turn off the power switch

• Turn off the main power switch for the QC-S300 and

unplug the power cord.

Remove the roller shaft.

• Pull the shaft and feed roller toward the near side of

the machine.

• Pull out the right end of the shaft.

Clean the feed roller.

• Clean the surface of the roller using a cloth with rub-

ber cleaner (XPF-111).

Install the roller shaft.

• When re-assembling, insert the projection on the

roller shaft into the U-shaped cutout on the fixed

end of the shaft.

• If double feeding or jamming occurs often even if

the feed roller has been cleaned, the roller may

be worn. Replace the roller with a new one.

2109640201A1

Cleaning a Feed Roller

WARNING

Turn off the main power switch and unplug

the power cord whenever a feed roller is

cleaned or replaced.

Roller Shaft

1

2

2109640201B1

2109640201C1

Feed Roller

CAUTION

When using rubber cleaner, wear rubber

gloves or clean your hands after the

cleaning operation.

2109640201D1

U-shaped Cutout

Projection

Additional

Information

Maintenance: Feed Rollers