219

SmartStacker User's Manual

If an Error Code Is Displayed on SmartStacker

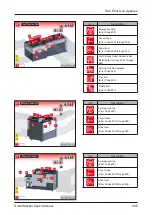

Code

Description and Causes

Solutions

345

Sheet delay in upper transport section

The B332 was activated while the B322 was

turned on. (Sheets were delayed in the upper

transport section. At the merging point, the order

of sheets may change.)

Check if the sheet thickness on the size setting

screen is correct.

If it is wrong;

In case of Near line or Inline

It should be corrected in the DFE.

In case of Offline

It can be corrected on the size setting screen.

Check if the trim is not jammed.

Also, check that the distance between the

stopper and the tail guide at the Merge Conveyor

is not too short.

350

Sheet has not arrived at lower transport section

sheet pass sensor

The B332 was not turned on within the specified

time.

Remove the sheet which is jammed. Also,

check if there is something to interrupt the

transportation of sheets. If this error code

appeared even though the sheet is not jammed,

check the B330 sensor is not dirty. (See page

372 for the cleaning instruction.)

If the same error occurs, check the distance

between stopper and the tail guide at the Merge

Conveyor is not short for the sheet. Also, check

if the sheet is not cut diagonally. If the sheet is

cut diagonally, see page 356 and adjust each

mechanism.

351

Sheet remains at lower transport section sheet

pass sensor

The B332 has remained on for longer than the

specified time.

Remove the sheet which is jammed. If this error

code appeared even though the sheet is not

jammed, check the B332 sensor is not dirty. (See

page 372 for the cleaning instruction.)

352

Too many sheets at lower transport section

The number of sheets between B330 and B332

exceeded the specified number.

Remove the sheet which is jammed. Also, check

the B330 sensor is not dirty. (See page 372 for

the cleaning instruction.)

353

Too many sheets passed lower transport section

sheet pass sensor

The number of the sheets detected by B332

exceeded the number of the sheets detected by

B330.

Remove the sheet which is jammed. Also, check

the B332 sensor is not dirty. (See page 372 for

the cleaning instruction.)

Summary of Contents for SmartStacker

Page 106: ...This page is intentionally left blank ...

Page 110: ...110 SmartStacker User s Manual Daily Safety Check Lift the cover pressing the hooks Hooks ...

Page 146: ...This page is intentionally left blank ...

Page 170: ...This page is intentionally left blank ...

Page 206: ...This page is intentionally left blank ...

Page 207: ...6 This chapter explains some possible problems and suggests some solutions 6 Troubleshooting ...

Page 367: ...367 SmartStacker User s Manual If a Jam Occurs B2 Stacker Option 10606650901C1 Feeder Option ...

Page 368: ...This page is intentionally left blank ...

Page 376: ...376 SmartStacker User s Manual SmartStacker Merge Conveyor Merge Stacker B2 Stacker Optional ...

Page 379: ...379 SmartStacker User s Manual SmartStacker B2 Stacker Optional Vacuum Belt ...

Page 381: ...381 SmartStacker User s Manual SmartStacker Merge Conveyor ...

Page 390: ...This page is intentionally left blank ...

Page 391: ...6 8 This chapter lists the specifications for this machine 8 Appendix ...

Page 411: ...This page is intentionally left blank ...

Page 412: ...Manufacturer Phone 81 75 934 6700 Fax 81 75 934 6708 www horizon co jp ...