3. Operation Procedures

69

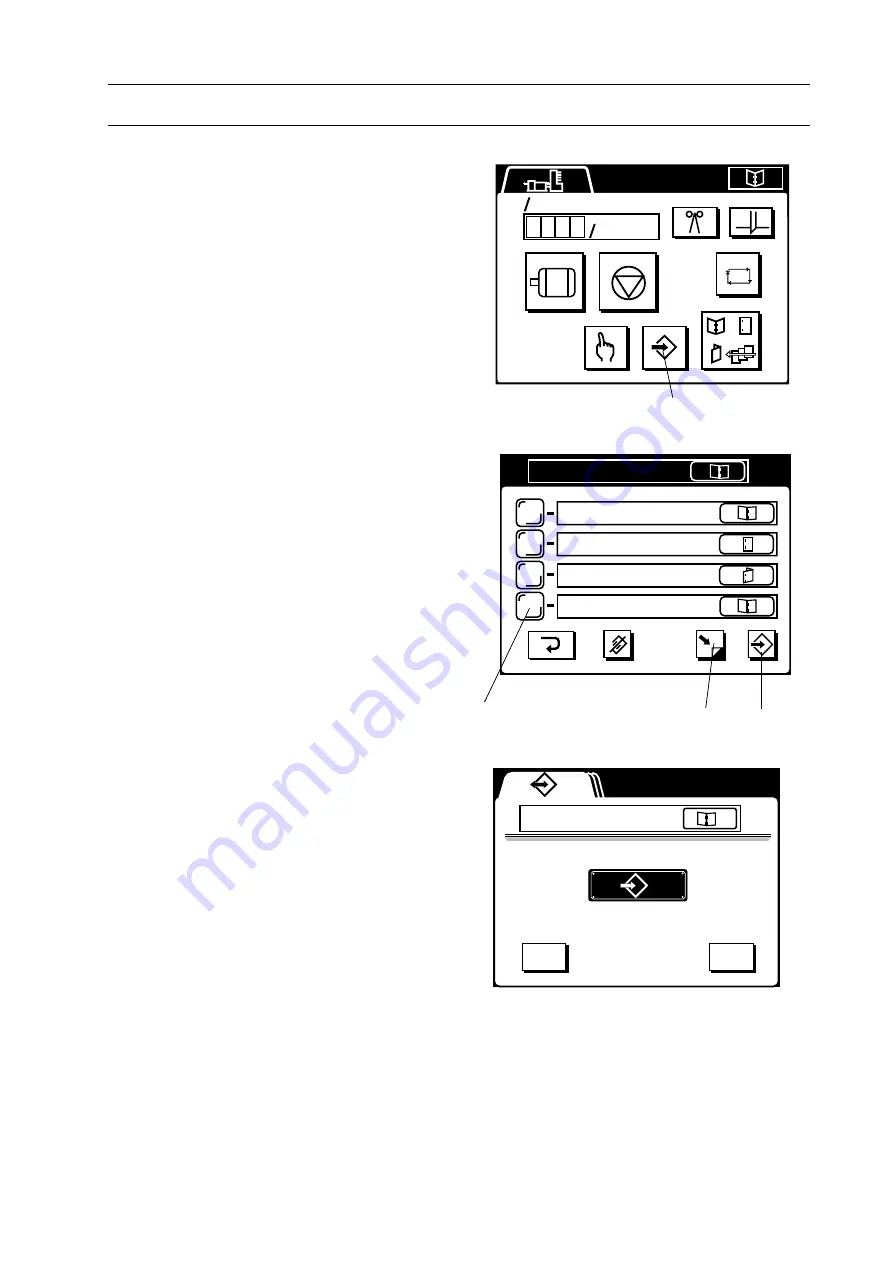

3-3 Job Memory

3-3-1 Write

Memory No.

This section shows how to memorize job

patterns.

1.

Press "Memory" icon on the binding

mode page.

2.

Select a memory No. to memorize the

job pattern.

NOTE

- SPF-20A has 12 memories. To indicate

memory No. 5 to 12, press "Next Page" icon.

3.

Press "Write" icon.

- The sheet size, the operation mode and

the date is memorized into the selected

memory No.

4.

Press "Yes" icon to confirm memory

write. When you cancel memory write,

press "No" icon.

Next Page

Memory

Write

60 min.

60 min.

X

X

X

X

X

1

2 9 7 . 0

2 9 7 . 0

4 2 0 . 0

2 9 7 . 0

2 1 0 . 0

2 9 7 . 0

4 2 0 . 0

2 1 0 . 0

2 9 7 . 0

4 2 0 . 0

2

3

4

X

OK?

NO

YES

2 9 7 . 0

4 2 0 . 0