EN

11

* Failsafe

If the receiver loses transmitter communication, the failsafe will activate. When activated, failsafe moves the throttle channel to its preset

failsafe position (low throttle) that was set during binding. All other channels move collectively and actively to place the aircraft in a slow descending left turn.

Binding

General Binding Tips

• The included receiver has been specifi cally programmed

for operation of this aircraft. Refer to the receiver manual

for correct setup if the receiver is replaced.

• Keep away from large metal objects while binding.

• Do not point the transmitter’s antenna directly at the receiver while binding.

• The orange LED on the receiver will fl ash rapidly

when the receiver enters bind mode.

• Once bound, the receiver will retain its bind settings

for that transmitter until you re-bind.

• If the receiver loses transmitter communication, the failsafe will

activate. Failsafe moves the throttle channel to low throttle. Pitch

and roll channels move to actively level the aircraft in fl ight.

• If problems occur, refer to the troubleshooting guide or if needed,

contact the appropriate Horizon Product Support offi ce.

General Binding Tips

The BNF Basic version of this airplane includes SAFE Select technology, enabling you to choose the level of fl ight protection. SAFE mode includes angle limits and

automatic self leveling. AS3X mode provides the pilot with a direct response to the control sticks. SAFE Select is enabled or disabled during the bind process.

With SAFE Select disabled the aircraft is always in AS3X mode. With SAFE Select enabled the aircraft will be in SAFE Select mode all the time, or you can assign a

switch to toggle between SAFE Select and AS3X modes.

Thanks to SAFE Select technology, this aircraft can be confi gured for full-time SAFE mode, full-time AS3X mode, or mode selection can be assigned to a switch.

IMPORTANT:

Before binding, read the transmitter setup section in this manual and complete the transmitter setup table to ensure your transmitter is properly

programmed for this aircraft.

IMPORTANT:

Move the transmitter fl ight controls (rudder, elevators, and ailerons) and the throttle trim to neutral. Move the throttle to low before and during

binding.

This process defi nes the failsafe settings.

You can use either the bind button on the receiver case or the conventional bind plug to complete the binding and SAFE Select process.

Note:

When using the auxiliary BEC from an ESC installed in the bind port of the receiver, unplug it to use bind plug.

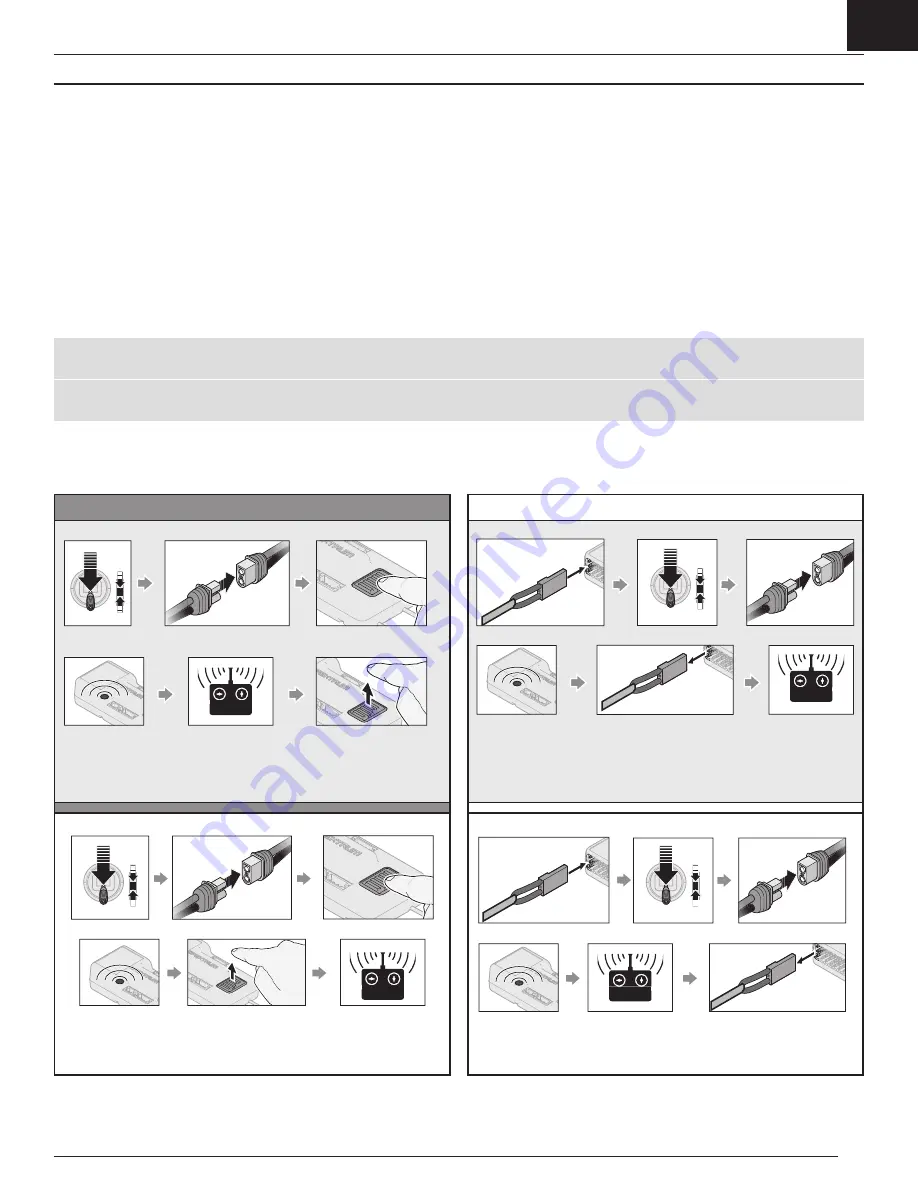

Using Bind Button

Using Bind Plug

SAFE Select Enabled

SAFE Select Enabled:

The control surfaces cycle back and forth

twice

with

a slight pause at neutral position every time the receiver is powered on.

Press and hold Bind

Button

Connect Power

Lower Throttle

Release Bind Button

Orange Flashing LED

Bind TX to RX

SAFE Select Enabled

SAFE Select Enabled:

The control surfaces cycle back and forth

twice

with a

slight pause at neutral position every time the receiver is powered on.

Install Bind Plug

Remove Bind Plug

Lower Throttle

Connect Power

Bind TX to RX

Orange Flashing LED

BIND

BIND

SAFE Select Disabled

SAFE Select Disabled:

The control surfaces cycle back and forth

once

every time the receiver is powered on.

Press Bind Button

Lower Throttle

Connect Power

Bind TX to RX

Release Bind Button

Orange Flashing LED

SAFE Select Disabled:

The control surfaces cycle back and forth

once

every time the receiver is powered on.

SAFE Select Disabled

Install Bind Plug

Connect Power

Lower Throttle

Remove Bind Plug

Bind TX to RX

Orange Flashing LED

BIND

BIND