Instruction Manual

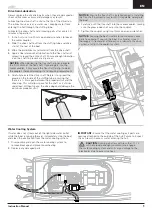

If water does not stream out of the right-side water outlet

while the boat is moving forward, immediately stop the boat

and clean the obstruction from the water-cooling system.

1.

Disassemble and clean the water cooling system to

remove blockage and prevent overheating.

2.

Replace any damaged parts.

IMPORTANT:

Ensure that the water cooling exit ports are

securely attached to the outside of the hull. Failure to inspect

this can result in excess water entering the hull.

CAUTION:

Running a battery with less than 11.1V

will not provide enough momentum to engage

the water-cooling system and will cause damage to the

electronics due to excessive heat.

Water Cooling System

9

EN

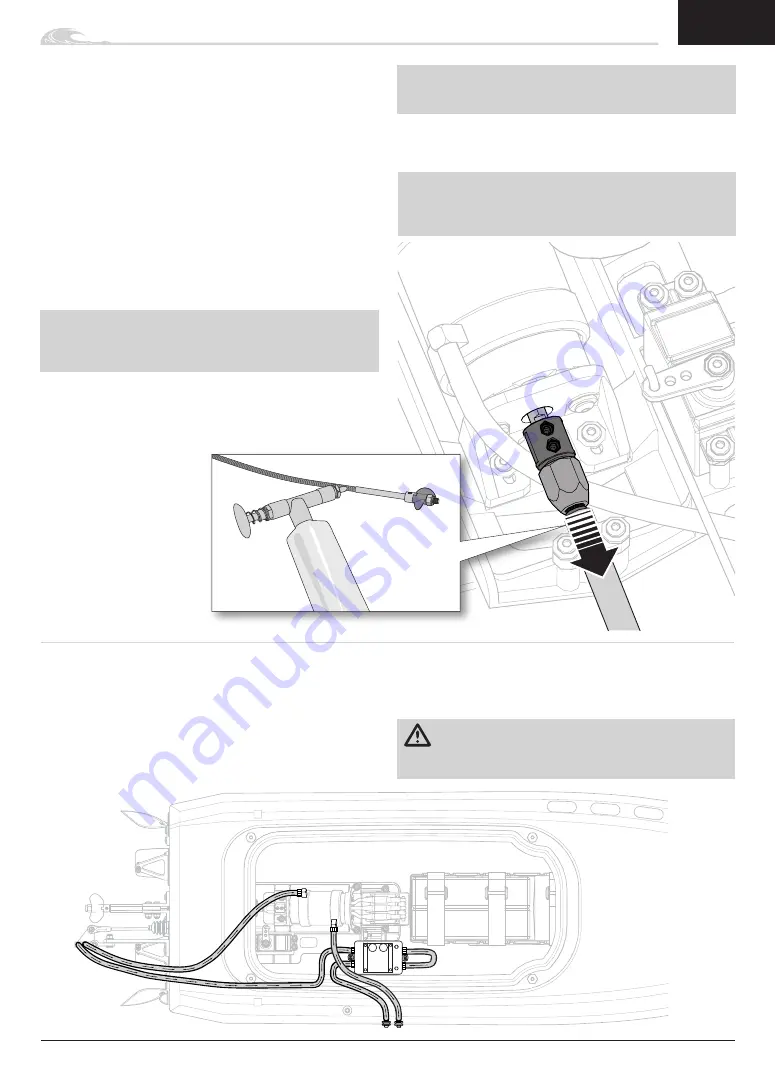

Always replace the drivetrain parts when they are damaged or

show visible wear or injury and damage may result.

Lubricating the drive shaft is vital to the life of the drivetrain.

The lubricant also acts as a water seal, keeping water from

entering the hull through the stuffing tube.

Lubricate the drive shaft and all moving parts after every 20

minutes of operation.

1.

In the hull, use two 10 mm open-end wrenches to loosen

the motor coupler.

2.

Slide the drive shaft out from the stuffing tube and drive

strut at the rear of the boat.

3.

Wipe the old lubricant and material from the drive shaft.

4.

Apply a liberal amount of lubrication to the flex shaft and

spread it around the entire shaft. Ensure enough lubrication

is on the shaft to prevent any dry areas.

NOTICE:

When lubricating the flex shaft, do not lubricate

the first 20mm of the flex shaft. If grease gets into the

motor coupler, it may cause the flex shaft to slip inside of

the coupler, thereby damaging it and requiring replacement.

5.

Carefully reinstall the drive shaft. Rotate it to spread the

grease on the inside of the stuffing tube, ensuring that

there is a 1–2mm gap between the propeller strut and the

drive dog. This will allow space for the shaft as it shrinks

under load. Without space, the drive dog could damage the

aluminum propeller strut.

NOTICE:

Ensure the flex shaft is installed correctly. Installing

the flex shaft incorrectly may result in irreparable damage to

the boat.

6.

Carefully push the flex shaft into the motor coupler, making

sure the grease does not carry into the coupler.

7.

Tighten the coupler using two 10mm open-end wrenches.

NOTICE:

Running the boat in saltwater could cause some

parts to corrode. If you run the boat in saltwater, rinse it

thoroughly in freshwater after each use, lubricate the drive

system, and flush the coolant system.

Drivetrain Lubrication