Section 3: Aileron/Flap Servo Installation

13

Required Parts

• Assembled wing

• 12" Servo extension (2)

(2 additional 24" for quad-flap configuration

wing)

• Standard size servos with mounting hardware (2)

(4 for quad-flap configuration)

Note

: The flap servo must be reversed if using a

Y-harness for flaps.

Required Tools and Adhesives

• Hobby knife

• Needle-nose pliers

• Drill

• Drill Bit: 1/16"

• Masking tape

• Pencil

• String with weight on end

• Phillips screwdriver (medium)

Step 1

Locate the servo openings in the bottom of each of the

wing halves. Use a sharp hobby knife to trim away the

covering over the openings. If you’re building the

conventional wing, you will only cut out the openings

that are closest to the wing root for the aileron servos.

If you build the quad-flap wing, trim away the covering

on all four servo openings in the wing. Use care not to

cut away too much of the covering.

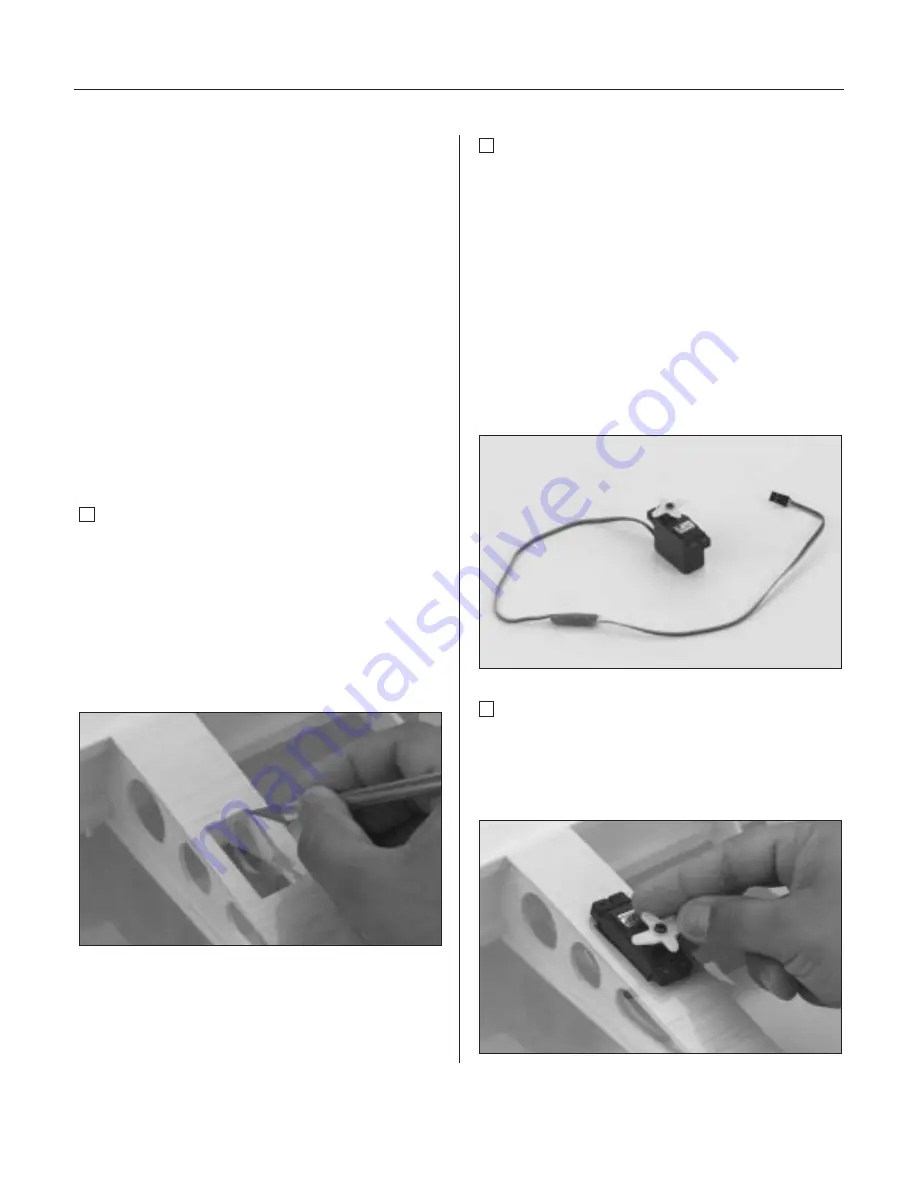

Step 2

Install the recommended servo hardware supplied with

your radio system onto your servos, (grommets and

eyelets). Install 12" servo extensions on the flap servo

lead and 24" extensions on the aileron servo leads.

Secure the connectors with either masking tape or a

commercial connector that prevents the servo lead

connections from becoming disconnected.

Hint

: It’s always a good idea to tape or secure

the servo connectors and servo extension

together to prevent the wires from becoming

unplugged inside the wing.

Step 3

Trial fit the servo into the servo opening. Depending upon

the type of servo installed, some trimming may be

required. Note that the servo is orientated so the servo

output shaft is closer to the trailing edge of the wing.