8

EN

Settings for Control Horns

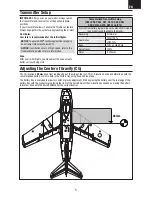

The following illustration shows the factory settings for

linkages on the control horns. After the initial fl ights, adjust

the linkage positions for the desired control response.

Aileron Elevator

Rudder

Before the fi rst fl ights, or in the event of an accident, make

sure the fl ight control surfaces are centered.

Adjust the

linkages mechanically if the control surfaces are not centered. Use

of the transmitter sub-trims may not correctly center the aircraft

control surfaces due to the mechanical limits of linear servos.

1. Ensure SAFE Select is OFF.

2. Make sure the control surfaces are neutral when

the transmitter controls and trims are centered. The

transmitter sub-trim must always be set to zero.

3. When needed, use a pair of pliers to carefully bend the metal linkage (see illustration).

4. Make the U-shape narrower to make the connector shorter. Make the U-shape wider to make the linkage longer.

Centering Controls After First Flights

For best performance with AS3X, it is important that excessive trim is not used.

Do not trim the aircraft while SAFE

Select is active. Always trim the aircraft in AS3X mode. If the model requires excessive transmitter trim (4 or more clicks

of trim per channel), return the transmitter trim to zero and adjust the linkages mechanically so that the control surfaces

are in the fl ight trimmed position.

Control Centering

Control Direction Test

Properly bind your aircraft and transmitter before

doing these tests. Make sure tail linkages move freely

and that paint or decals are not interfering with them.

Switch on the transmitter and connect the battery.

Use the transmitter to operate the aileron and

elevator controls. View the aircraft from the rear when

checking the control directions.

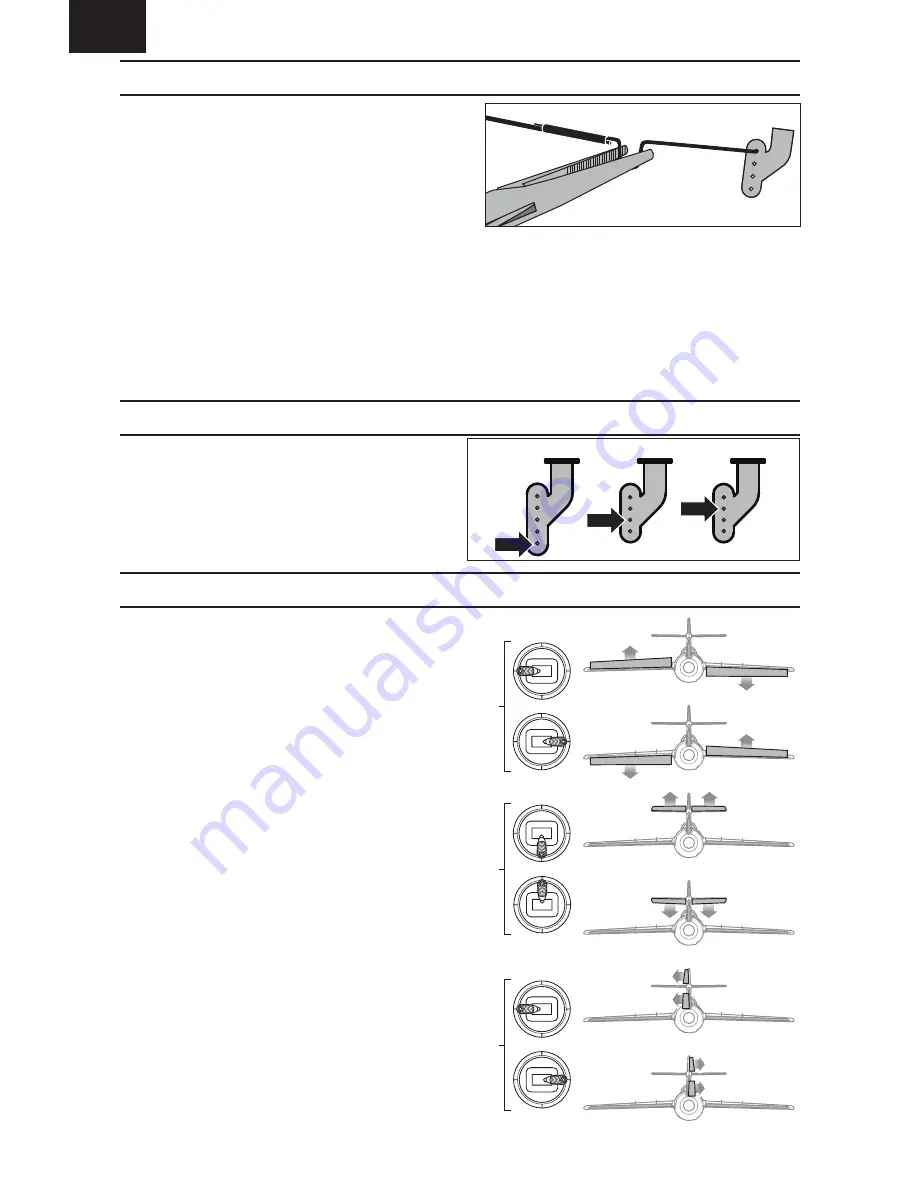

Ailerons

1. Move the aileron stick to the left. The right aileron

should move down and the left aileron up, which

will cause the aircraft to bank left in fl ight.

2. Move the aileron stick to the right. The right

aileron should move up and the left aileron

down, which will cause the aircraft to bank right

in fl ight.

Elevators

3. Pull the elevator stick back. The elevators should

move up, which will cause the aircraft to pitch

up in fl ight.

4. Push the elevator stick forward. The elevators

should move down, which will cause the aircraft

to pitch down in fl ight.

Rudder

5. Move the rudder stick to the left. The rudder

should move to the left, which will cause the

aircraft to yaw left in fl ight.

6. Move the rudder stick to the right. The rudder

should move to the right, which will cause the

aircraft to yaw right in fl ight.

Aileron stick

Elevator stick

Rudder stick