- 9 -

Clean, inspect and lubricate all cases

before resizing.

Using a case lube pad or Hornady

®

One Shot

®

Case Lube,

it is easy to lubricate the body portion of the bottle neck

cases. A minimum of lubricant should be used on the

neck portion since trapped lubricant may cause the

shoulder to buckle. Too little or no lubricant may easily

result in a stuck case.

Place a lubricated case in the shell holder

and pull the operating handle.

If using the manual prime system, you will need to insert

a primer before inserting a case into the shell holder. The

case can then be sized/de-primed, and re-primed on the

downward stroke of the ram.

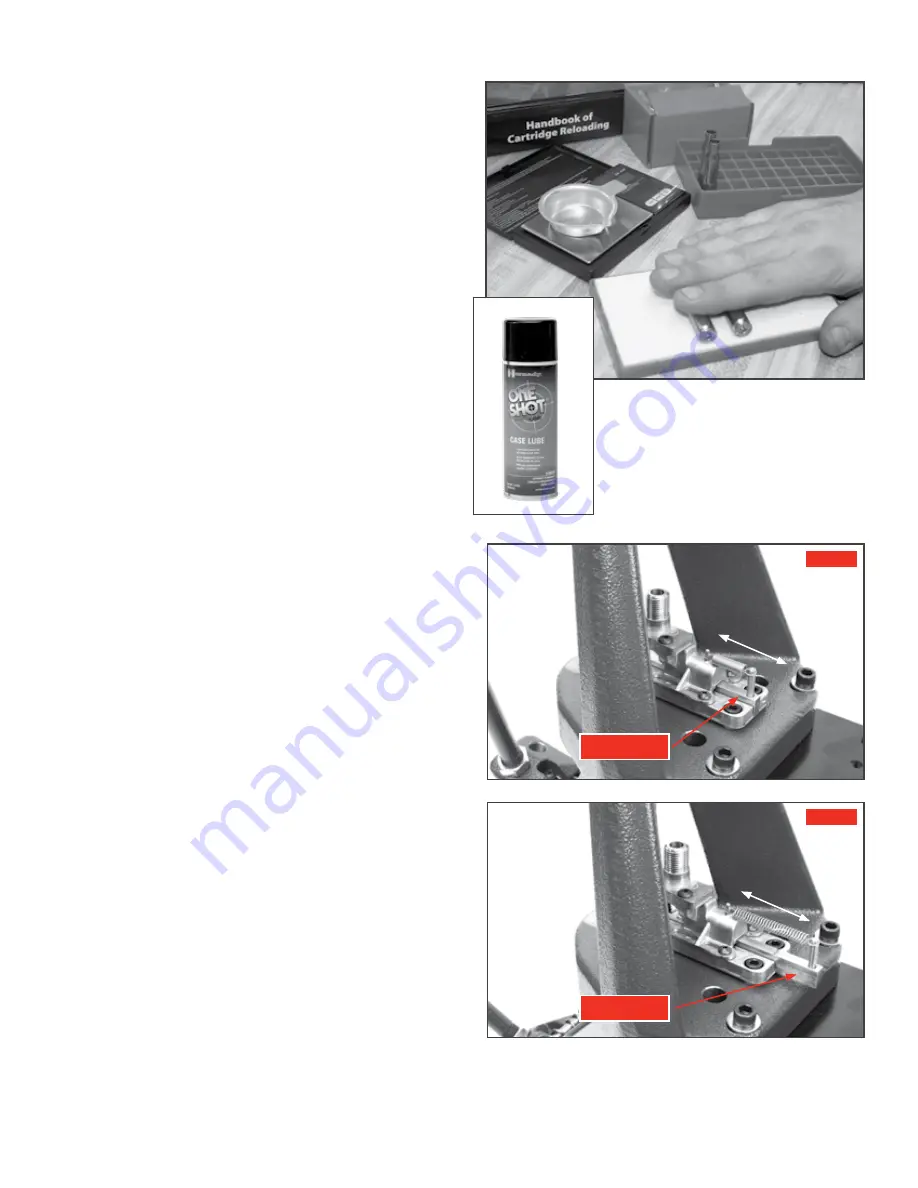

If using the auto prime system, you should see the priming

shuttle start to move as the ram moves upwards (Figures 14

and 15). If there is tension and the shuttle does not move,

check to make sure there are no obstructions, and the

shuttle is lightly lubricated.

As the ram moves upwards and the shuttle moves to

the rear, it should release a primer from the tube and

into the priming cup. The spent primer being removed

from the case should also fall into the primer catch tray.

Adjustments to the decap pin in the size die may be

necessary to “time” the dropping of the spent primer – see

below. Ideally, the spent primer will be ejected from the

case at the very top of the ram’s stroke.

Setting Decap Timing

Primers falling too soon, missing the tray – Move decap pin

up by threading it counter-clockwise.

Primers not falling (timing too slow) – Move decap pin

down by threading it clockwise.

Check case for length and do case prep work.

After the case has been sized and de-primed, the case may

be removed from the press for case prep. First, measure

for overall length. If needed, trim the case, and chamfer/

deburr the mouth. This is also the ideal time to ream the

primer pocket if it has a military crimp.

Priming Shuttle

Priming Shuttle

Figure 14

Figure 15