3

2

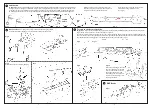

Fig. 2

Fig. 1

Fig. 3

Lubrication

IMPORTANT – Only apply small single drops of light machine oil to the places indicated in red. This is best achieved by

making a simple oil “dropper” as illustrated in Fig.1. Insert a straightened paper clip into a cork and use a bottle cap as

a container for the oil. A small drop of oil can then be picked up by the dropper and applied in exactly the right place.

Immediately wipe off any excess oil, especially from the locomotive and tender bodies. Only lubricate moving parts.

Apply one drop of oil to each of the valve gear

and connecting rod pivot points indicated in red

in Fig.2, on both sides of the locomotive.

Apply one drop of oil to the gear and each

of the axle bearings indicated in red.

(See Fig.3).

Accessories

The chain guard, vacpipes and articulated coupling cannot

be fitted if the front coupling is to be used when running the locomotive.

Fig.8

Fig.7

DCC Ready

Fig.10

Fig.4

To remove the locomotive body

Important: If your model is fitted with a speedometer cable, detach this first from the left hand rear driving wheel

(Fig.7). Keep screw and spacer safe until the body is replaced.

Turn the locomotive upside down and remove the screw beneath the bogie. (Fig.8). Turn the locomotive right way up

and ease the front end of the chassis downward from the body. When the front of the chassis is clear of the body, pull

the chassis forward to disengage the rear chassis lugs from the rear of the body. (Fig.9).

Fig.5

Alternative pony truck wheels (flanged).

Fig.6

Fig.9

When re-assembling, make sure

the rear chassis lugs are located

into the slots inside the rear of

the body as shown in Fig.10.

Ease body back into place and

replace the chassis fixing screw

and bogie assembly.

Fig.11

1

2

3

4