3

2

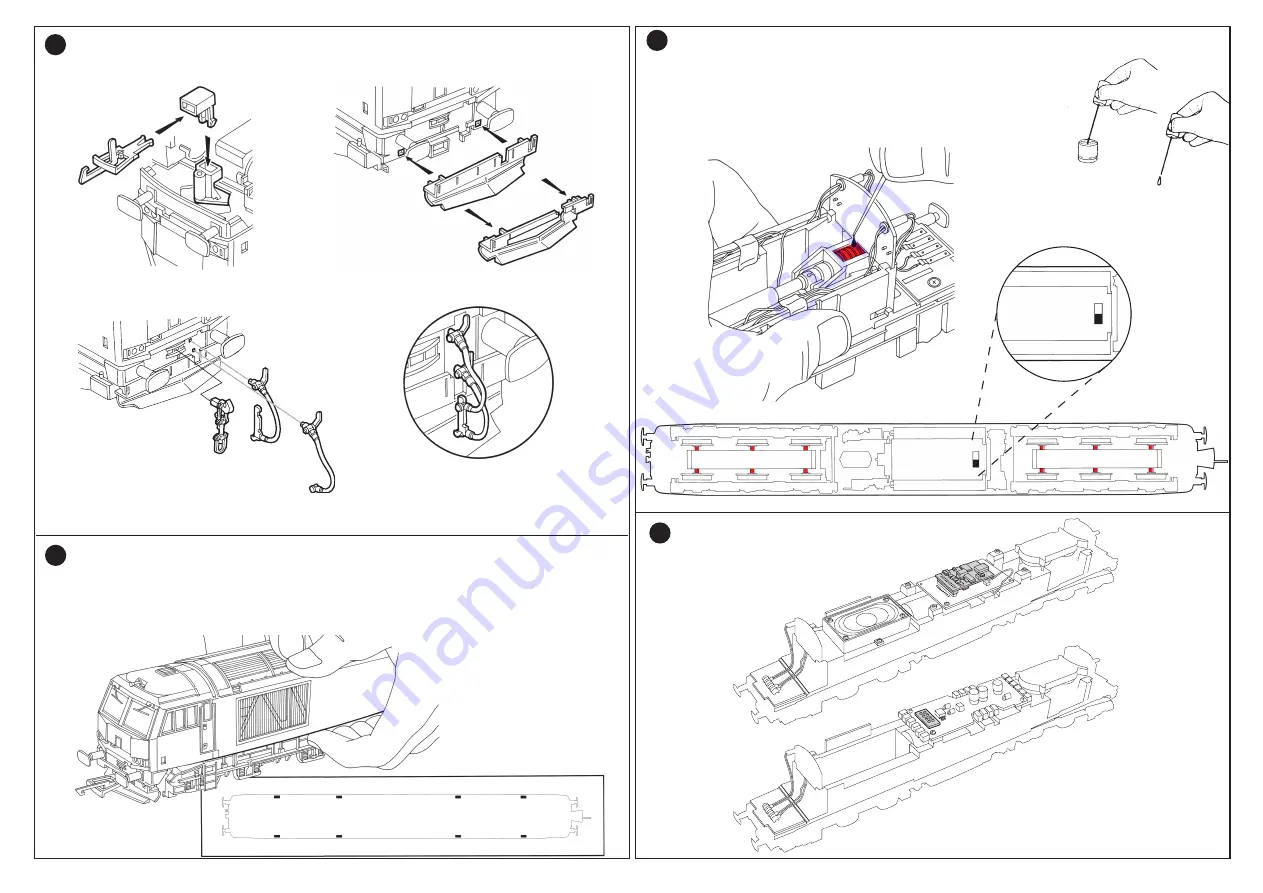

Fig.3a

Fig.6

Lubrication

IMPORTANT – Only apply small single drops of light machine oil to the places

indicated in red in Figs.6 and 7. This is best achieved by making a simple oil

‘dropper’ as illustrated in Fig.5. Insert a straightened paper clip into a cork and

use a bottle cap as a container for the oil. A small drop of oil can then be picked

up by the dropper and applied in exactly the right place. Immediately wipe off

any excess oil, especially from the locomotive body. Only lubricate moving parts.

Fig.5

Fig.7

Accessories

To fit alternative snow plough

Remove coupling pocket, (Fig.1), then remove pre-fitted snow plough and fit alternative as shown, (Fig.2).

To fit vacuum hoses and articulated coupling, locate as shown in Fig.3 and Fig.3a

Fig.1

Fig.2

Fig.4a

Fig.3

Note:

When fitting the alternative snow plough, vacuum hoses and articulated coupling, the coupling pocket, (Fig.1),

must be removed.

N

D

N

D

Switch for day-time and

night-time lighting.

Sound / DCC Ready

Location of Sound/DCC Decoder (Fig.4) and

DCC Ready socket (Fig.5)

4

Fig.4

Fig.5

1

3

Body Removal

Due to the weight of the chassis, this should only be carried out on a flat, stable surface.

Position hands centrally either side of the body as shown in Fig.4. Unclip the sides from the chassis by easing the

sides outwards, (the body clip positions are shown in Fig.4a), and carefully lift the body clear. Ensure that both

ends of the body are kept equally level when lifting, as pulling the body up from one end only may cause damage.

Fig.4

2