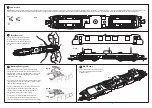

Lubrication

1

Fig.1

IMPORTANT – Only apply small single drops of light machine oil to the places indicated in red in Fig.2. This is best achieved by making a simple oil ‘dropper’ as illustrated in Fig.1. Insert a straightened paper clip into a cork and use a bottle

cap as a container for the oil. A small drop of oil can then be picked up by the dropper and applied in exactly the right place. Immediately wipe off any excess oil, especially from the locomotive body. Only lubricate moving parts.

2

3

Fig.2

Fig.3

Fig.4

Body

Removal

2

Unclip the body sides from the chassis

(Fig.3), making sure all the lugs are free

from the holes in the body as indicated in

red in Fig.4. The body will lift off easily

(Fig.4).

Some Hornby locomotives are fitted with operating

pantographs for use with the Hornby Overhead Power

Supply System. In these locomotives, power can be either

obtained from the overhead catenary wire or from the

track in the normal way.

To operate a locomotive from the overhead supply, raise

the pantograph and slide the roof power selector switch

towards the pantograph (Fig 5a).

To run a locomotive with an operating pantograph on a

layout without an overhead supply system, slide the

selector switch away from the pantograph and leave

pantograph in its lowered position (Fig 5b).

It is important to follow carefully, the instructions

sup-plied with the Overhead Power Supply System

products, particularly with regard to catenary wire height.

Working Pantographs

3

Fig. 5a

DCC

Ready

If your locomotive is not pre-fitted with

a decoder, please see Fig.6 for location

of DCC socket.

4

Fig.6

Fig. 5b