10

LONGHORN 12V INSTRUCTION MANUAL

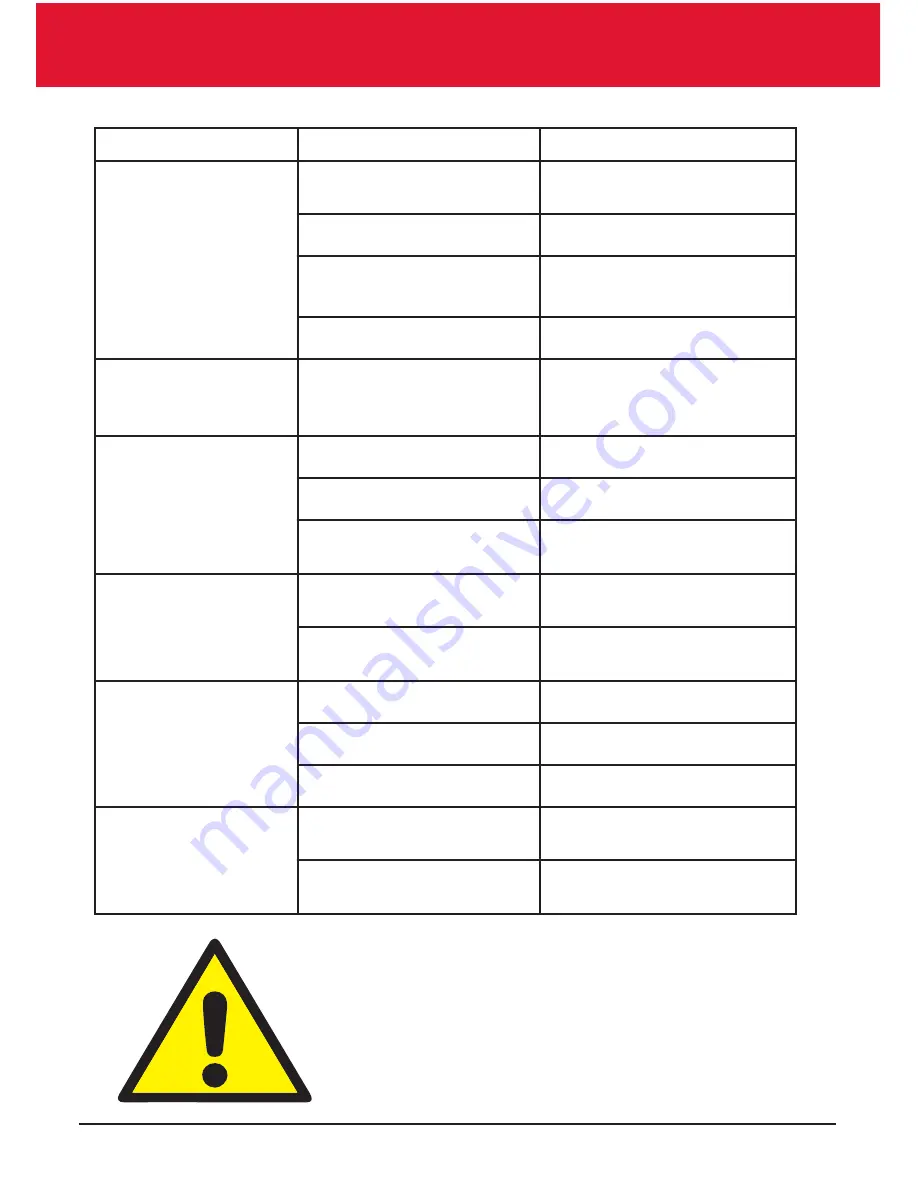

TROUBLESHOOTING

Problem

Cause

Solution

Motor does not

start

Poor battery lead

connections

Check connections and

condition of wires / clips

Faulty switch

Have switch replaced

Damaged relay

Have relay replaced

Burnt out motor

Have motor replaced

Motor struggles

to start or runs

slowly

Worn brushes

Have brushes replaced

Motor is noisy

Faulty bearings

Have bearings replaced

Damaged cooling fan

Have cooling fan replaced

Debris in the cooling fan Remove debris or have

machine serviced

Flexi drive is noisy

Lack of lubrication

Oil or grease the inner

drive

Damaged/worn inner

drive

Replace inner drive

Solid drive is

noisy / vibrates

Lack of lubrication

Oil or grease the guts

Damaged/worn guts

Replace affected gut

Dry spot on eye spindle

Have solid drive serviced

Cannot connect

handpiece

Worn or broken

bayonet/worm end

Replace bayonet/worm

end

Faulty/worn spring in

bayonet end

Replace bayonet spring

and/or bayonet end

Electrical work and servicing should only be

carried out by suitably qualified personnel.