8

LONGHORN 12V INSTRUCTION MANUAL

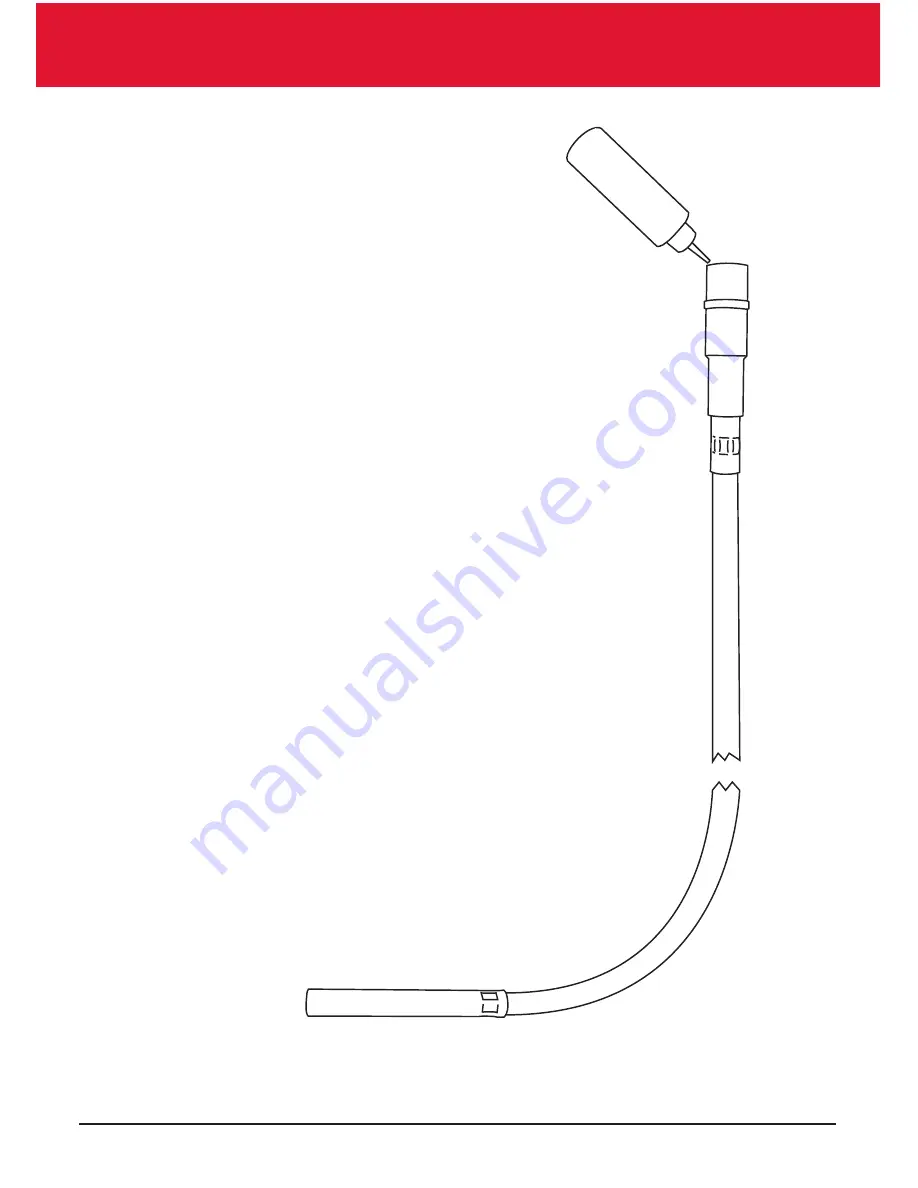

FLEXI DRIVE LUBRICATION

Oiling the driveshaft

Frequency:

after every 4 hours of use

Directions

• Remove the handpiece and the driveshaft

• Add oil into the top of the driveshaft

• Re-fit driveshaft to the machine

Greasing the driveshaft

Frequency:

After every 40 hours of use or annually

Directions

• Remove the handpiece and the driveshaft

• Unscrew the top EasyDrive male fitting

• Unscrew the bottom bayonet fitting

• Pull the inner drive from the top of the outer drive

• Grease inner whilst feeding back into the outer

• Re-fit the bayonet end

• Re-fit the EasyDrive male fitting

• Attach driveshaft to the machine

SAE 30

LONGHORN

OIL