MAN0508-03

08 JUN 2005

PAGE 3

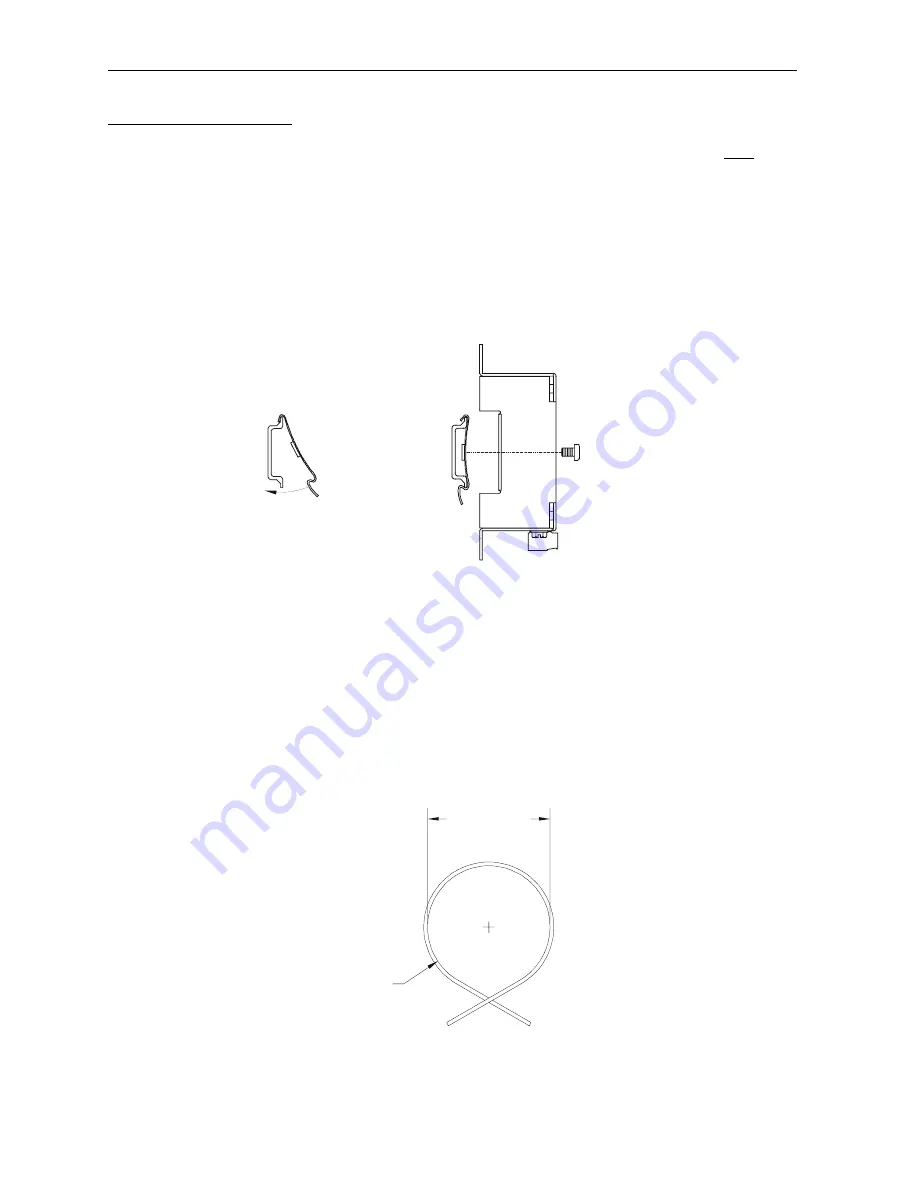

b. DIN-Rail

Mounting

1.

Read the Installation Chapter in the hardware manual of the controller you are using prior to

mounting the FOX104 / FOX404. Observe requirements for the panel layout design and

adequate clearances. A checklist is provided for your convenience in the hardware manual. (See

the

Additional References

section in this document.)

2.

Determine length of DIN-Rail needed. (Refer to Figure 2.)

3.

Noting the proper location, attach two (2) DIN-Rail mounting clips (included with FOX unit) to the

DIN-Rail by hooking the clips over the top of the Rail and rocking down and snapping over the

bottom of the Rail. (Refer to Figure 3.)

4.

Adjust clips as necessary by sliding them along the DIN-Rail to align with the holes in the tabs of

the FOX unit. Using the provided screws, mount the Fox unit to the clips. Tighten screws as

necessary to hold the unit securely. (Refer to Figure 3.)

Figure 3 – (Left) DIN-Rail and Mounting Clips, and (Right) FOX104 / FOX404 DIN-Rail Mounting

2.4

Fiber Optic Cable Installation

Important considerations for installing the FOX include the following guidelines:

a.

To ensure reliable communication between the FOX base and OCS/RCS module, high quality

cables need to be installed. See Table 2 for fiber cable part numbers.

b.

The maximum fiber optic cable distance is 10 meters between drops.

c.

During installment of the fiber optic cable, all direction changes need to adhere to a

Minimum

Bend Radius

of one inch (25.44mm).

Figure 3 – Fiber Optic Cable Bend Radius

1.00” (25.4mm) Min.

Bend Radius

001FOX011

2.00” (50.8mm)

Min. Diameter

001FOX012

Close-up of mounting clips

being hooked on to DIN-rail.

DIN-Rail

Mounting

Clips

FOX104 /

FOX404