Maintenance location

Work instructions

Interval

Hydraulics

WARNING

Lower all hydraulically lifted parts (e.g. wings, packer, undercarriage,

etc.) to the ground before performing any work on the hydraulic system.

Depressurise the hydraulics on the tractor and implement side!

Hydraulic system and components

Check all hydraulic components and hoses for function,

leak tightness, fastening and chafing

40 h

hydraulic hoses

Check the hydraulic hoses regularly for damage (cracks, chafing, etc.).

Replace damaged and faulty hoses immediately.

Hydraulic hoses must be replaced after 6 years. For this purpose pay

attention to the manufacturing date on the crimp sleeve (year/month)

and the hose (quarter/year):

Crimp sleeve

Hose

Depending on the conditions of use (e.g. weather influences) or in case of

higher strains on the machine the hoses may need to be replaced earlier.

Have the hydraulic system checked by an expert at least once every year.

In addition follow the country specific regulations and directives.

NOTES:

•

The maintenance interval designates maintenance on each working day before working with the machine.

•

Follow additional maintenance notes in the respective chapters.

Lubrication points

(Lubrication grease: DIN 51825 KP/2K-40) - Number of lubrication points in brackets

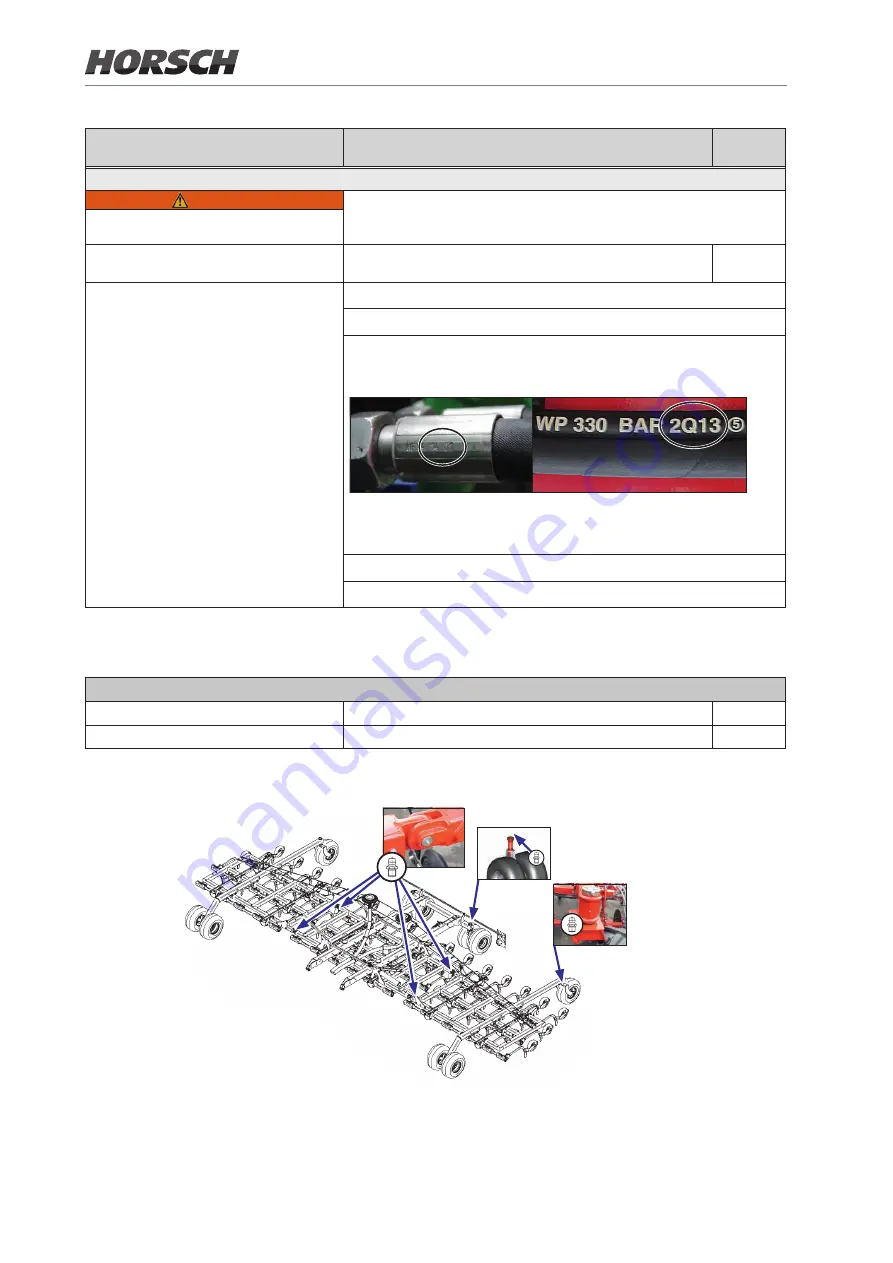

Fig.1 Locking bolt

lubricate (4)

40 h

Fig. 2/3 Undercarriage pivot bearing

lubricate (4)

Daily

Fig. 2 (2x)

Fig. 3 (2x)

Fig.1

Lubrication points with the addition "2x" can be found on either side of the machine.

44