24

Before attempting to load the header wagon, ensure the wagon is either attached to the tow vehicle or the wheels have

been secured with wheel chocks to prevent unwanted movement during the loading process. To start using the header

wagon, two basic adjustments should be made for the initial setup:

• Universal Header Supports

•

Top Rail System

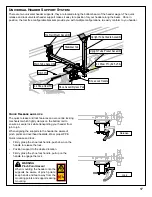

Universal Header Supports

To prevent potential injury, avoid working around the

wagon with the header positioned above it. To ensure

safe working conditions, move the header away from the

wagon when making adjustments.

Determine the type of header that you have and configure

the universal header supports to best fit your header.

(page 17)

• Header support width

• Cradle height

Configure header

supports

Position header

support

Adjust the position of the header support along the wagon

bottom rail to align upright tube cradle under the header

tube frame

Ensure the frame of the header will sit firmly on the cradle

assembly.

Position the header evenly from front to back on the

wagon, do not position the header beyond the front of the

top rail to ensure there is adequate clearance between the

tow vehicle and header. If extra clearance is required the

tongue may be extended up to 91.5 cm (3.0’).

Initial Setup

!

WARNING

Pinch Hazard

Keep hands away from mounting

points and supports while loading the

header. Potential pinch hazard exist

between the wagon and header

SL00003

!

CAUTION

Operational Hazard

Chock wheels when

loading or unloading the

wagon to prevent unwanted

movement

SNL00002

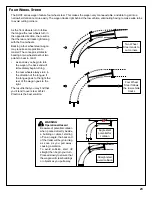

Top Rail Setup

Review your swather and header owner manual, determine where the front main cross beam is located (generally along

the nylon pads behind the cutter bar on a grain header.)

Remember to detach any power connections (hydraulic, PTO etc) and release any safety latches, bracket or pins between

the header and feeder house

Take measurements, and adjust the top rail on the wagon to align with the front main beam on the header.

Ensure the header main cross beam is aligned with the wagon top rail, or damage could result from insufficient support on

the header.

Adjust the height of the top rail so that the header beam will make contact with the wagon before the heal of the header.

This will simplify removing and loading header.

Summary of Contents for Contour SHCF36

Page 2: ...2 Notes ...