Instruction Manual

Microprocessor Temperature Regulator HT MC11

Page 17 of 22

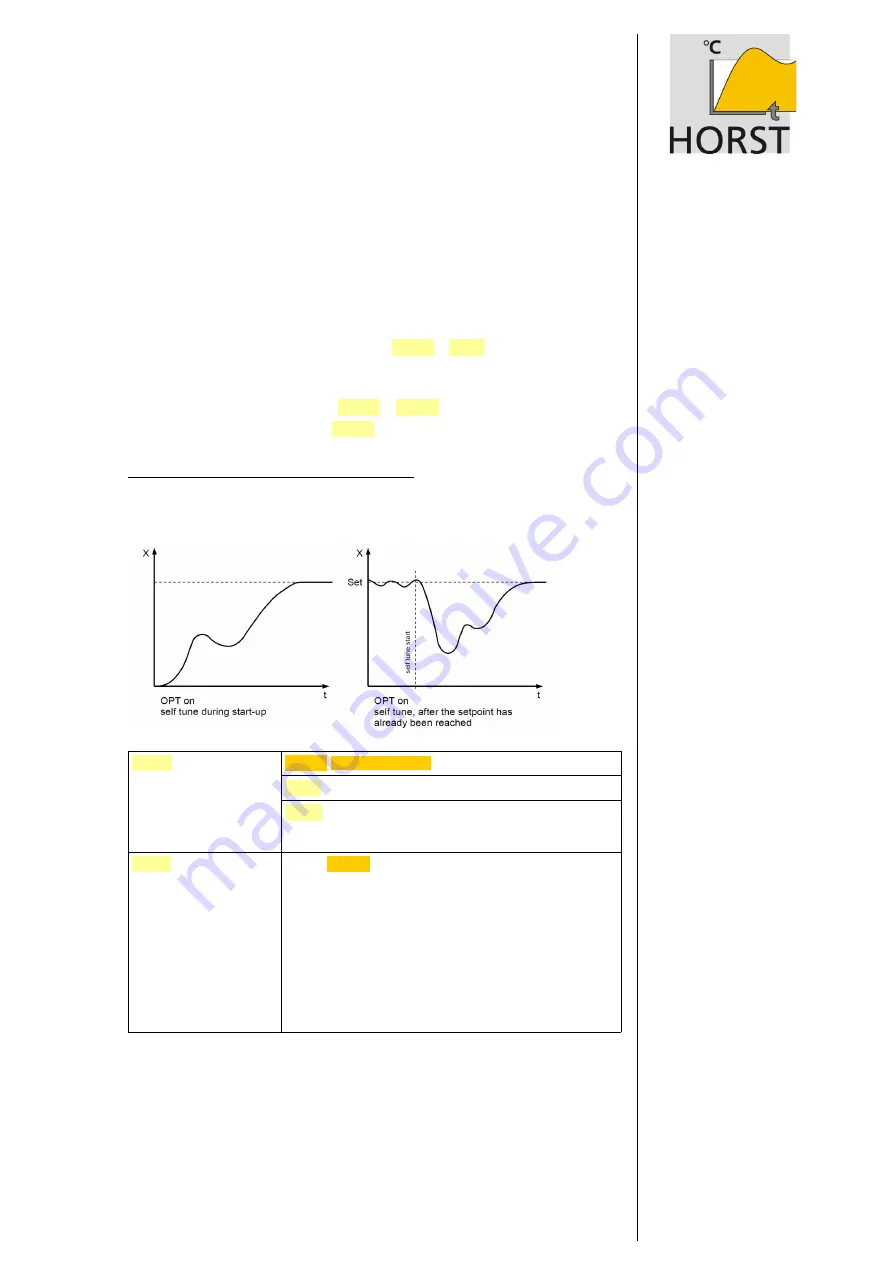

Autotune:

The tuning algorithm determines characteristic values within the controlled process

and calculates valid feedback parameters (P, D, I) and cycle time (= 0.3 x D) for a PD/I-

controller.

The autotune mode is activated during start-up shortly before the setpoint is reached.

If autotune is activated after the setpoint has already been reached, the temperature

will first fall approx. 5 % below the measuring range in order to determine optimal

control system parameters.

Autotune can be initiated any time by setting

OPt

=

on

.

After finishing calculation of feedback parameters, the controller leads the process

value to the setpoint value.

Autotune can be stopped by setting

OPt

=

OFF

.

During autotune the display shows

OPt

alternating with the setpoint value.

Preconditions for starting the autotune algorithm:

•

Setpoint value must be higher than 5 % of measuring range

•

Sensor must not have a failure

•

Softstart function must not be active

OPt

autotune

OFF

autotune not active

on

autotune active (one time)

Auto

Autotune starts each time the controller is turned on if

the difference between setpoint and actual process

value is more than 7 % of the measuring range.

OFSt

process value Offset

-999

OFF

1000

Parameter for correction of input signal:

•

correction of a gradient between measuring point and sensor

tip

•

line resistance balancing of 2-line RTD (Pt100) sensors

•

correction of control deviation when using P or PD action

Example: if the offset value is set to +5 °C, the real temperature

measured by the sensor (when process is balanced) is 5 °C less

than the setpoint and the displayed actual process value.

Ensure that the corrected temperature process value is within

the selected measuring range.

Version 1080/1.03 02/2018

471 11 400

Horst GmbH

Bitzenheimer Weg 10

D-64653 Lorsch

Telefon: +49 (0) 6251 9626 0

Telefax: +49 (0) 6251 9626 96