50

6) Displaying Ongoing Error

Keep pressing the Option Button in the ICE or STOP mode.

The Display Window will show the compressor operating hours ([b] - 3).

Press and release the Stop Button to display the error record ([b] - 5).

The most recent errors will be displayed in reverse order of occurrence.

When “– –“ appears, press and release the Stop Button.

The Display Window will show the ongoing error.

Release the Option Button to return to the original mode.

7) Resetting Error Record

Before resetting the errors, record them on the Inspection Record attached to the Front

Panel.

With the Operation Switch in the OFF position, keep pressing the Stop + Option Buttons

together, and turn ON the Operation Switch.

Release the Buttons when the Display Window shows the ICE mode.

The error record has been reset. Do NOT use this command unless necessary.

8) Displaying Gear Motor Errors

Keep pressing the Option Button in the ICE or STOP mode.

The Display Window will show the compressor operating hours ([b] - 3).

Press and release the Stop Button to display the error record ([b] - 5).

The most recent errors will be displayed in reverse order of occurrence.

When “– –“ appears, press and release the Stop Button ([b] - 6).

Press and release the Stop Button to indicate numerals and/or letters six times.

When “– –“ appears, release the Option Button to return to the original mode.

The numerals and/or letters are indicated in hexadecimal notation.

The numerals 0 - 9 are used as 0 - 9, A as 10, b as 11, C as 12, d as 13, E as 14, and F as

15.

In other words, they need conversion to decimal notation by calculating “1st numeral or

letter x 16 + 2nd numeral or letter”.

The converted number presents the frequency of occurrence.

(Example)

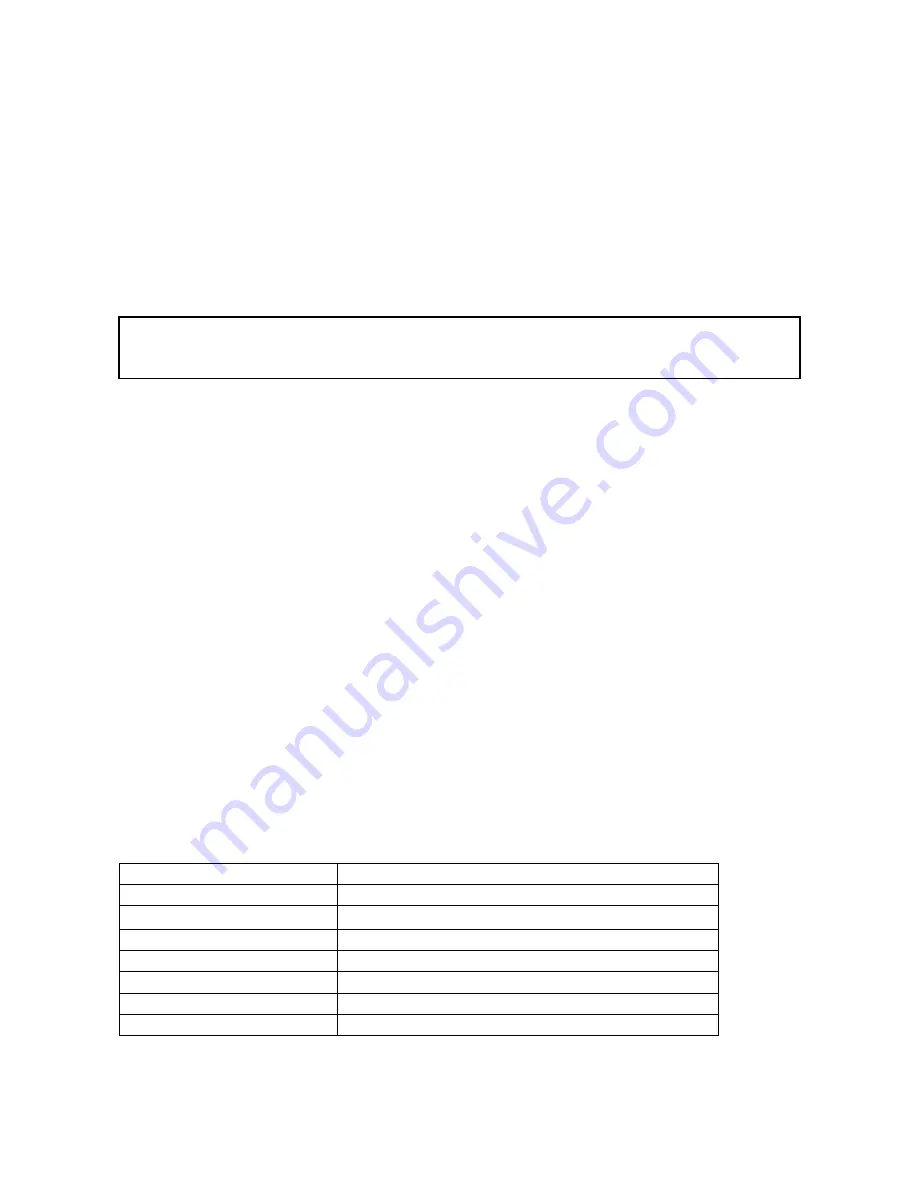

Seven Segment Display

Frequency of Occurrence in Decimal Notation

00

0 x 16 + 0 = 0 time

08

0 x 16 + 8 = 8 times

10

1 x 16 + 0 = 16 times

36

3 x 16 + 6 = 54 times

A1

10 x 16 + 1 = 161 times

C0

12 x 16 + 0 = 192 times

FF

15 x 16 + 15 = 255 times

The numerals and/or letters will appear in the following order:

Summary of Contents for FM-300AFE-HC

Page 7: ...3 2 DIMENSIONS CONNECTIONS a FM 481AGE HC FM 481AGE HCN ...

Page 8: ...4 b FM 300AFE HC FM 300AFE HCN ...

Page 9: ...5 3 SPECIFICATIONS a FM 481AGE HC ...

Page 10: ...6 b FM 481AGE HCN ...

Page 11: ...7 c FM 300AFE HC ...

Page 12: ...8 d FM 300AFE HCN ...

Page 14: ...10 Drier Ice Chute Pressure Switch ...

Page 23: ...19 b FM 300AFE HC FM 300AFE HCN Pressure Switch Cut out 22 6 1 5 0 bar Cut in 15 7 1 5 bar ...

Page 24: ...20 2 WIRING DIAGRAM a WIRING DIAGRAM FM 481AGE HC FM 481AGE HCN ...

Page 25: ...21 FM 300AFE HC FM 300AFE HCN ...

Page 26: ...22 b CONTROL BOX LAYOUT FM 481AGE HC FM 481AGE HCN ...

Page 27: ...23 FM 300AFE HC FM 300AFE HCN ...

Page 35: ...31 FM 300AFE HC FM 300AFE HCN ...

Page 36: ...32 ...

Page 37: ...33 c SEQUENCE FM 481AGE HC FM 481AGE HCN 1 Startup Water Supply ...

Page 39: ...35 FM 481AGE HC FM 481AGE HCN 3 Startup Ice production starts ...

Page 40: ...36 FM 481AGE HC FM 481AGE HCN 4 Normal Operation Bin Control ...

Page 41: ...37 FM 481AGE HC FM 481AGE HCN 5 Shutdown Compressor stops 5 min ...

Page 42: ...38 FM 481AGE HC FM 481AGE HCN 6 Shutdown Drain ...

Page 43: ...39 FM 300AFE HC FM 300AFE HCN 1 Startup Water Supply ...

Page 45: ...41 FM 300AFE HC FM 300AFE HCN 3 Startup Ice production starts ...

Page 46: ...42 FM 300AFE HC FM 300AFE HCN 4 Normal Operation Bin Control ...

Page 47: ...43 FM 300AFE HC FM 300AFE HCN 5 Shutdown Compressor stops 5 min ...

Page 48: ...44 FM 300AFE HC FM 300AFE HCN 6 Shutdown Drain ...