12

II. MAINTENANCE AND CLEANING INSTRUCTIONS

IMPORTANT

1. This icemaker must be maintained individually, referring to the instruction manual

and labels provided with the icemaker.

2. To achieve optimum icemaker performance, the following parts need periodic

inspection and maintenance:

Extruding head (upper bearing)

Housing (lower bearing)

Mechanical

seal

These parts should be inspected after two years from installation or 10,000 hours of

operation, whichever comes first, and once a year thereafter. Their service life,

however, depends on water quality and environment. More frequent inspection and

maintenance are recommended in bad or severe water conditions.

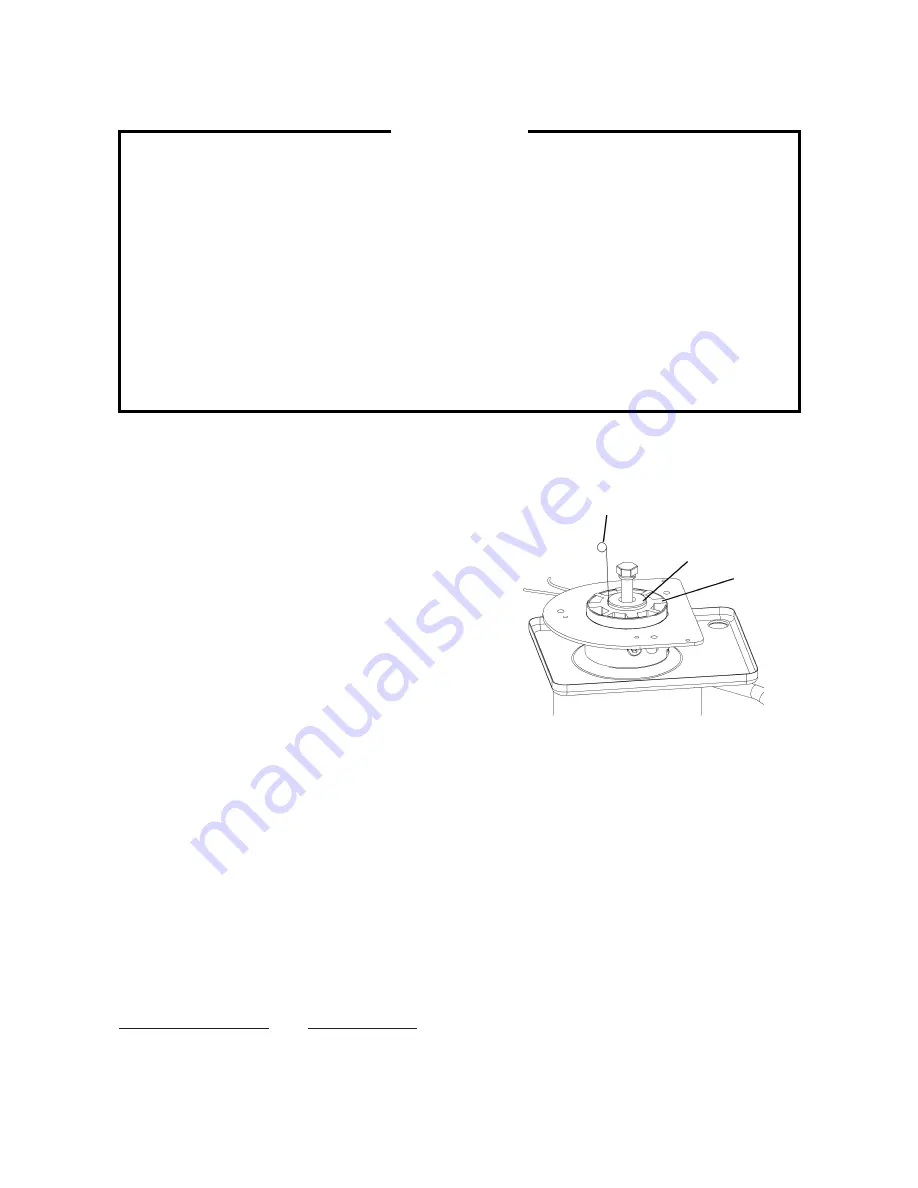

1. EXTRUDING HEAD (UPPER BEARING), HOUSING (LOWER BEARING)

These parts should be replaced if a diametrical gap

of more than 0.5 mm is found when at least three

spots are checked by changing the direction of the

auger on each bearing.

It depends on the water quality and conditions, but

normally the bearings should be checked for wear

after a total of 8,000 - 10,000 hour operation from

installation date.

Note: The clearance between the auger blades

and the evaporator interior is 0.4 - 0.5 mm. If

the bearings and rotating parts are worn out

to create a larger clearance, the evaporator

interior may be damaged. (The diameters

differ by 0.8 - 1.0 mm.)

If the auger surfaces against which the bearings contact are no longer smooth or

show any burrs or abrasions during the above inspection, replace the auger. The

sealing bolt must be tightened equally to torque of 784N

·

cm

±

10%.

2. MECHANICAL SEAL

The mechanical seal prevents water leaks from between the auger and the housing bearing

and gradually wears out to reduce its watertightness. Check the amount of water leakage

from the drain pipe located at the side of the gear case to determine the necessity of

replacement.

Total operation time

Water leakage

3,000 hours

0.1 mL/h

10,000 hours

0.5 mL/h

For reference only

(May differ from actual design)

Auger

0.5 mm Round Stock

or Pin Gauge

Extruding

Head

Summary of Contents for FM-300AKE-HC

Page 4: ...1 I SPECIFICATIONS 1 DIMENSIONS SPECIFICATIONS a FM 300AKE HC Auxiliary code D 0 or earlier ...

Page 5: ...2 b FM 300AKE HC Auxiliary code D 1 or later ...

Page 6: ...3 c FM 300AKE HCN Auxiliary code D 0 or earlier ...

Page 7: ...4 d FM 300AKE HCN Auxiliary code D 1 or later ...

Page 8: ...5 e FM 480AKE HC Auxiliary code D 0 or earlier ...

Page 9: ...6 f FM 480AKE HC Auxiliary code D 1 or later ...

Page 10: ...7 g FM 480AKE HCN Auxiliary code D 0 or earlier ...

Page 11: ...8 h FM 480AKE HCN Auxiliary code D 1 or later ...

Page 21: ...18 2 WIRING DIAGRAM a WIRING DIAGRAM FM 300AKE HC N Auxiliary code D 0 or earlier ...

Page 22: ...19 FM 300AKE HC N Auxiliary code D 1 or later ...

Page 23: ...20 FM 480AKE HC N Auxiliary code D 0 or earlier ...

Page 24: ...21 FM 480AKE HC N Auxiliary code D 1 or later ...

Page 33: ...30 b TIMING CHART ...