Summary of Contents for FM-300AKE-HC

Page 4: ...1 I SPECIFICATIONS 1 DIMENSIONS SPECIFICATIONS a FM 300AKE HC Auxiliary code D 0 or earlier ...

Page 5: ...2 b FM 300AKE HC Auxiliary code D 1 or later ...

Page 6: ...3 c FM 300AKE HCN Auxiliary code D 0 or earlier ...

Page 7: ...4 d FM 300AKE HCN Auxiliary code D 1 or later ...

Page 8: ...5 e FM 480AKE HC Auxiliary code D 0 or earlier ...

Page 9: ...6 f FM 480AKE HC Auxiliary code D 1 or later ...

Page 10: ...7 g FM 480AKE HCN Auxiliary code D 0 or earlier ...

Page 11: ...8 h FM 480AKE HCN Auxiliary code D 1 or later ...

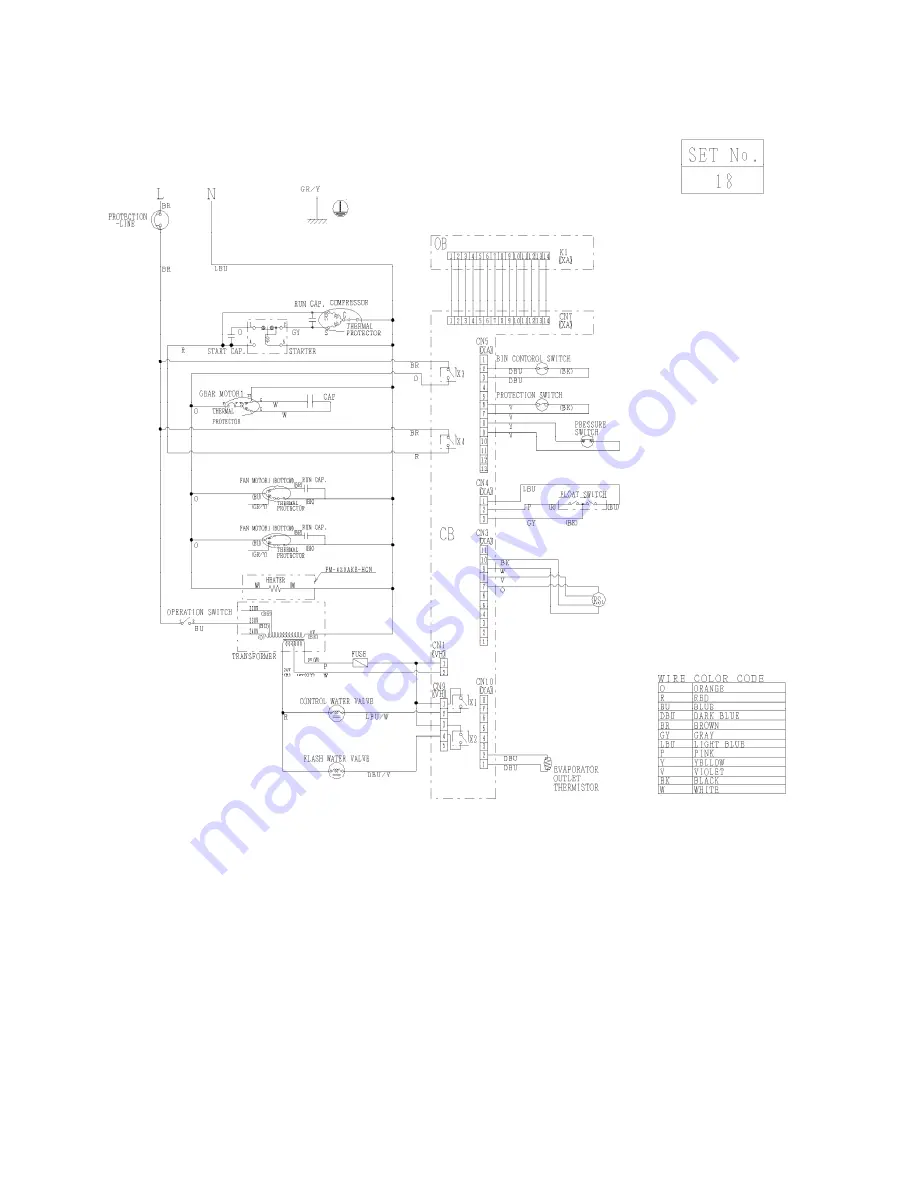

Page 21: ...18 2 WIRING DIAGRAM a WIRING DIAGRAM FM 300AKE HC N Auxiliary code D 0 or earlier ...

Page 22: ...19 FM 300AKE HC N Auxiliary code D 1 or later ...

Page 23: ...20 FM 480AKE HC N Auxiliary code D 0 or earlier ...

Page 24: ...21 FM 480AKE HC N Auxiliary code D 1 or later ...

Page 33: ...30 b TIMING CHART ...