9

B. Service Diagnosis

PROBLEM

POSSIBLE CAUSE

REMEDEY

[1] Showcase will not

start.

1. Power switch (earth leakage circuit

breaker) in OFF position.

1. Turn ON.

2. Unplugged.

2. Plug in.

3. Supply voltage too low.

3. Plug into a properly earthed,

independent wall outlet of 220 -

240V ± 6%.

4. No power supply to the wall outlet.

(Breaker or fuse blown.)

4. Correct.

5. Electrical circuit open or bad

contacts.

5. Correct.

6. Motor protector tripped.

6. Allow to cool. If fan motor does not

energize, replace fan motor.

[2] Poor cooling

performance

1. Gas leaks.

1. Repair the leaks and recharge.

2. Fan motor defective.

2. Replace.

3. Condenser and/or air filter clogged.

3. Clean.

4. Condenser air inlet blocked.

4 - 9. Instruct the user on

characteristics and proper use

of the showcase.

See "II.A.

Operating Instructions."

5. Exposed to direct sunlight or high

wattage lamps shining on the case.

6. Located next to a high heat

producing equipment.

7. Doors opened too frequently or left

open.

8. Packed with foods, or warm or hot

foods inside.

9. Ambient temperature exceeding

30°C.

10. Frost formed.

10. See (*) below for characteristics

and proper use of the showcase.

[3] Dry foods

1. Foods have been stored from the

previous day.

1 - 2. Instruct the user on

characteristics and proper use

of the showcase.

2. Foods have been stored for a long

time.

[4] Condensation

formed.

1. [Exterior] Relative humidity

exceeding 60%.

1. Wipe off excessive frost with a soft

cloth.

* During operation, moisture inside the showcase causes frost to build up on the

evaporator pipe inside. Frost has an insulating effect on the evaporator pipe and

reduces refrigeration performance. Every time the door is opened, warm and humid

air comes in and raises the interior temperature to accelerate frost formation. Opening

of the doors should be kept to a minimum to maintain proper operating temperatures.

Do not leave the doors open continuously. Since frost on the evaporator pipe reduces

refrigeration performance, the showcase cannot be used continuously. After business

hours, return sushi materials to a refrigerator and turn off the showcase. Leave the

showcase off for at least 1 to 2 hours to defrost. Failure to defrost the showcase will

result in improper operating temperatures. In some conditions, frost may build up in a

short time and reduce cooling performance. In these conditions, defrost the showcase

as needed during the day. While defrosting the showcase, move sushi materials to a

refrigerator to prevent deterioration.

Summary of Contents for HNC-120BE-L-BH

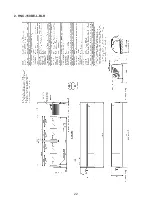

Page 22: ...21 VI Technical Information A Dimensions Specifications 1 HNC 120BE L BLH...

Page 23: ...22 2 HNC 150BE L BLH...

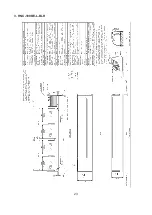

Page 24: ...23 3 HNC 180BE L BLH...

Page 25: ...24 4 HNC 210BE L BLH...

Page 26: ...25 5 HNC 120BE R BLH...

Page 27: ...26 6 HNC 150BE R BLH...

Page 28: ...27 7 HNC 180BE R BLH...

Page 29: ...28 8 HNC 210BE R BLH...

Page 30: ...29 9 HNC 120BE L BH...

Page 31: ...30 10 HNC 150BE L BH...

Page 32: ...31 11 HNC 180BE L BH...

Page 33: ...32 12 HNC 210BE L BH...

Page 34: ...33 13 HNC 120BE R BH...

Page 35: ...34 14 HNC 150BE R BH...

Page 36: ...35 15 HNC 180BE R BH...

Page 37: ...36 16 HNC 210BE R BH...