16

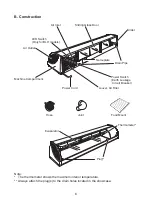

5. Center Frame (Except HNC-120 Type)

Remove the two flat head machine screws (black)

securing the center frame to the rear and the two

machine screws securing the center frame to the top

frame. Tilt the center frame and release it from the

joint.

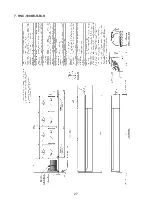

6. Holder - Evaporator Pipe

Remove the truss head tapping screw (4 x

30) from the bottom of the top frame. Take

off the center frame. Be careful with the

evaporator pipe. It will be released and hang

down. Remove the truss head tapping screw

(4 x 10) from the bottom of the top frame.

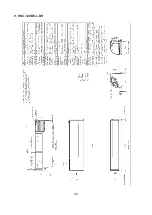

7. Refrigeration Assembly

IMPORTANT

Follow the instructions in “DANGER” and

“WARNING” for flammable refrigerant use

and “III. A. Refrigeration Circuit Service

Information”.

Remove the sliding door, side cover, top

cover, top frame and side frame. Take off the

compressor terminal cover and remove the

starter and motor protector. Uninsulate the

expansion valve and unbraze the outlet pipe

(see “C. Constant Pressure Expansion Valve”).

Unbraze the joint indicated. Remove the four

machine screws securing the refrigeration

assembly. The whole refrigeration assembly

can be pulled out.

Fig. 3

Fig. 4

Truss Head Tapping

Screw 4 x 30

Truss Head Tapping

Screw 4 x 10

Holder -

Evaporator Pipe

Evaporator Pipe

Fig. 5

Outlet Pipe

Joint

Expansion Valve

Summary of Contents for HNC-120BE-L-BH

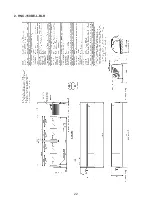

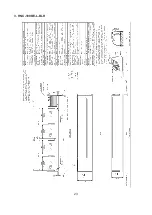

Page 22: ...21 VI Technical Information A Dimensions Specifications 1 HNC 120BE L BLH...

Page 23: ...22 2 HNC 150BE L BLH...

Page 24: ...23 3 HNC 180BE L BLH...

Page 25: ...24 4 HNC 210BE L BLH...

Page 26: ...25 5 HNC 120BE R BLH...

Page 27: ...26 6 HNC 150BE R BLH...

Page 28: ...27 7 HNC 180BE R BLH...

Page 29: ...28 8 HNC 210BE R BLH...

Page 30: ...29 9 HNC 120BE L BH...

Page 31: ...30 10 HNC 150BE L BH...

Page 32: ...31 11 HNC 180BE L BH...

Page 33: ...32 12 HNC 210BE L BH...

Page 34: ...33 13 HNC 120BE R BH...

Page 35: ...34 14 HNC 150BE R BH...

Page 36: ...35 15 HNC 180BE R BH...

Page 37: ...36 16 HNC 210BE R BH...