7

ENGLISH

3) Check that the refrigerant lines do not rub or touch lines or other surfaces, and that the fan blade turns freely.

4) Recommended parts and materials listed below will be required.

Cord

17 AWG (1.0 mm²) three-wire cord will be required for the fan motor wiring

between the icemaker and the condenser unit (L+N+

).

Copper tubing

Phosphorous deoxidized copper tubing. Two tubes of the same diameter will

be required for refrigerant lines. Mark them for a distinction between the gas

line and liquid line to prevent misconnection.

9.52 (OD) x 7.93 (ID) - gas

9.52 (OD) x 7.93 (ID) - liquid

Pipe insulation (for gas and liquid pipes)

To withstand temperatures up to 120°C.

Bolt

Four M8 hexagon bolts for securing the condenser unit.

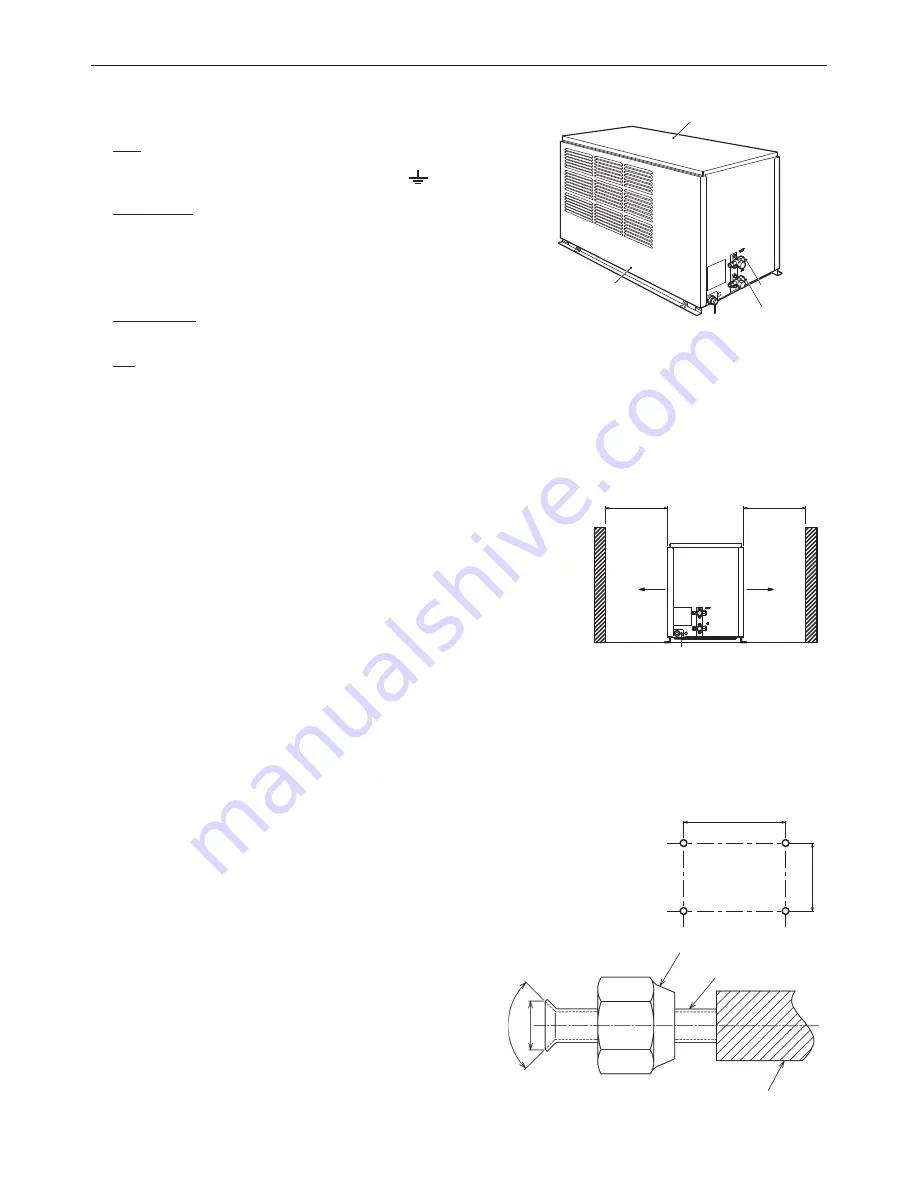

5) Do not remove the unit cover before finishing installation, to prevent damage to the air-cooled condenser.

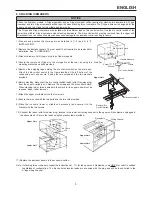

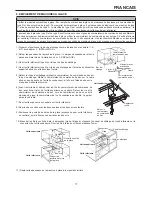

[b] LOCATION

The condenser is intended for outdoor use and must be positioned in a permanent well ventilated side under the following

guidelines:

* Select a firm and flat site.

* Should not be exposed to harsh or adverse weather conditions.

* Preferably a dry and well ventilated area with 60 cm clearance on both front and

rear for ease of maintenance and service should they be required.

* Normal condenser ambient temperature: +1°C to +40°C. Temperatures not within

this operating range may affect the production capacity of the icemaker.

* When the condenser unit is installed on a roof, a 50 cm height base is recommended to prevent heat reflection and to avoid

the possibility of the unit standing in water.

* The maximum line length is 10 m. For information on longer line installations, contact the nearest Hoshizaki Service office. (See

the instruction manual for contact details.)

* The condenser should not be installed more than 6 m above the height of the icemaker or more than 2 m below it.

Note: If the recommended guidelines of the installation are exceeded, the icemaker performance may be reduced.

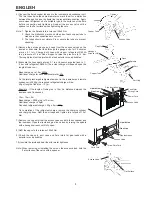

[c] INSTALLATION

1) This condenser unit is provided with four mounting holes. Secure the condenser unit with four

bolts.

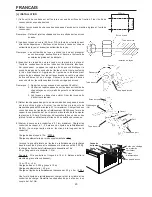

2) Remove the flare nut from each of the access valves on the icemaker and condenser unit.

Note: Remove and discard the copper caps on the flare nuts.

3) The two copper tubes (9.52 mm OD) to be provided on site should

be insulated separately. Place the flare nuts onto each end of the

tubes and flare the tube ends.

Note: The tube ends to be flared should be free from damage,

cracks and burrs and also clear of grease or scraps.

Unit Cover

Top Panel

Liquid Line

Gas Line

Air

Air

Min. 60cm clearance

500mm

380mm

Flare Nut

Copper Tube

Pipe Insulation

90°±0.5

13.2-14 DIA