11

ENGLISH

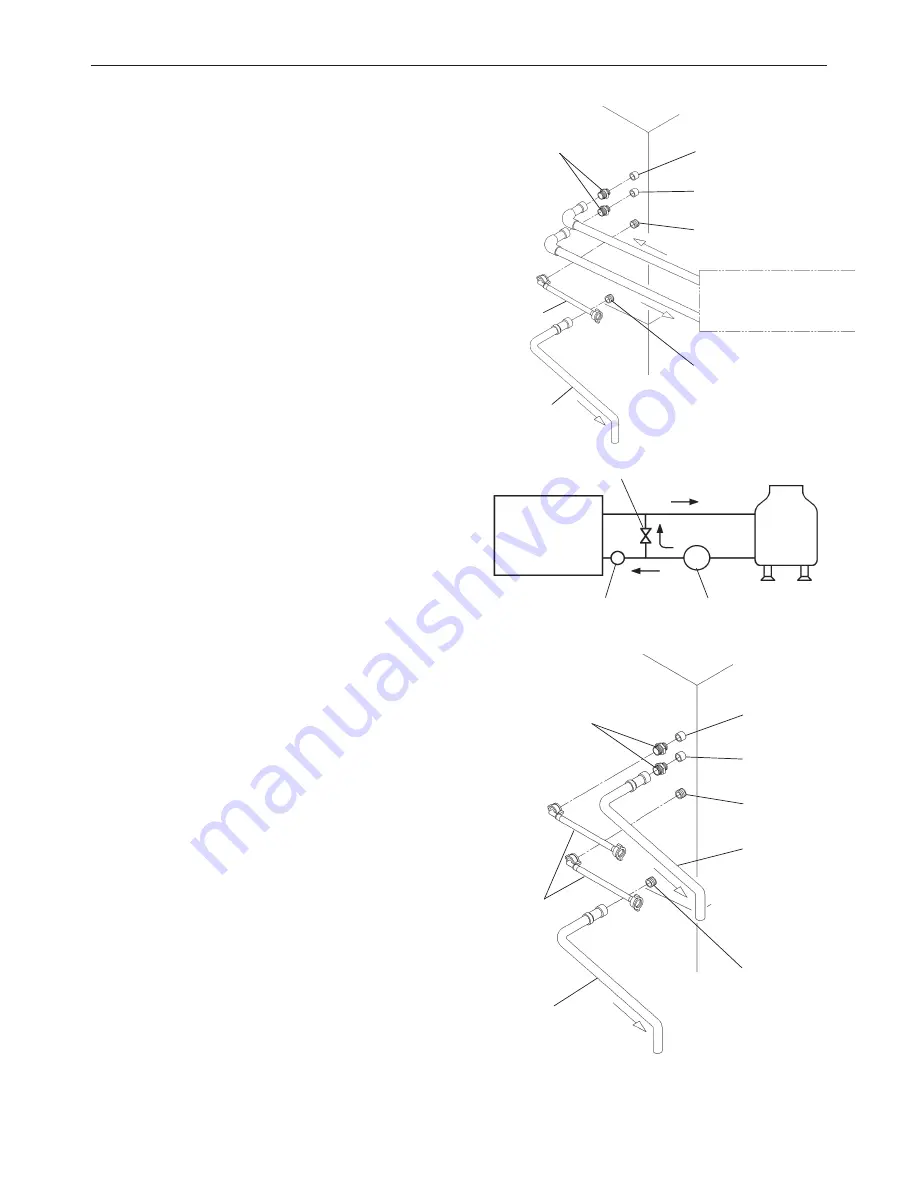

[a] Standard connections according to WRAS regulations in

U.K.

* When selecting a cooling tower, refer to the following peak values

of heat flow in the condenser:

Model IM-240AW:

5235 W

* Pipes between the cooling tower and the icemaker should be

at least 20 mm DIA to reduce pressure loss, even though the

icemaker fittings are 13 mm DIA.

* Pressure loss in the water circuit inside the unit will be 5 to 6 m

when the cooling water flows at the ratio of 4 to 5 lit/min.

* Select a circulating pump referring to the above values of heat

flow.

* Do not use a cascade pump, or the water regulator will vary the

flow and stop it during the defrost cycle.

[Icemaker Connections]

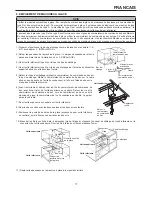

1) Attach the angled end of flexible inlet hose (accessory) to the

G3/4 fitting on the rear of the icemaker as indicated, ensuring

rubber sealing washer is correctly positioned. Hand tighten

sufficiently to provide leak free joint.

2) Attach the other end of inlet hose to the water tap, noting washer

is correctly positioned before hand tightening as above.

Note: If filtration or treatment is used, ensure icemaker section

only is on treated water supply, not the condenser.

3) Attach grey flexible outlet hose (accessory) to the R3/4 fitting on

the rear of the icemaker as indicated, confirming fitment of rubber

washer before finally hand tightening the joint. The hose can be

cut to length as necessary to suit position of main drain.

4) By means of a suitable spanner or wrench, tighten the 1/2-

3/4 nipples (accessory) into the Rc1/2 fittings on the rear of the

icemaker as indicated. P.T.F.E. tape and/or a suitable sealing

compound should be used to obtain a leak free joint.

Note: Jointing compounds should be approved and suitable for

potable water use.

5) Connect the condenser cooling circuit to the free end of 1/2-3/4

nipples as indicated using a suitable rigid type pipe.

[b] Connections according to regulations other than WRAS by

utilising accessory hoses

1) Follow the instructions from 1) to 4) in [a] above.

2) For condenser connections, use supplied accessory hoses and

make the same connections as 1) to 3) in [a] above to the free

end of 1/2-3/4 nipples as indicated.

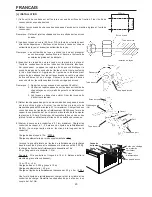

10. START-UP PROCEDURE

1) Open the water tap.

2) Connect the power supply and energise.

3) The display indicates “on”.

Icemaker

Cooling

Tower

Flow Control Valve

Strainer

Pump

P

Potable Water

Inlet G3/4

Inlet Hose

Drain Outlet R3/4

Outlet Hose

Cooling Water

Inlet Rc1/2

Cooling Water

Outlet Rc1/2

1/2-3/4 Nipple

Condenser Cooling Circuit

Icemaker

Bin

Water-Cooled Model [a]

Potable Water

Inlet G3/4

Inlet Hose

Outlet Hose

Drain Outlet R3/4

Cooling Water

Inlet Rc1/2

Cooling Water

Outlet Rc1/2

1/2-3/4 Nipple

Icemaker

Bin

Outlet Hose

Water-Cooled Model [b]