28

f)

Refrigerant Pressures, HM, and TXV Diagnosis: If evaporator is still not cooling,

check refrigerant pressures. See "VIII.B. Performance Data."

Next, check HM operation. If refrigeration pressures are above HM setpoint and

HM is bypassing, replace HM. Check TXV for proper operation. Remove TXV bulb

and hold it in your hand, refrigerant low-side pressure should rise, place TXV bulb in

ice water, refrigerant low-side pressure should drop. A 10 to 15 pound pressure swing

between warm and cold conditions indicate a good TXV. If a 10 to 15 pound swing is

not present, replace TXV.

g)

WRV Diagnosis: WRV is factory set and generally no adjustment is required.

If WRV fails to open in freeze, check for proper refrigerant pressures. See "VIII.B.

Performance Data." If refrigerant pressures are correct and WRV does not open,

adjust or replace as needed. See "IV.C. Water Regulating Valve Adjustment

(water-cooled models)."

h)

Freeze Termination Diagnosis: After 5 min. in freeze, disconnect CB K5 FS

connector. 15 sec. later appliance should switch out of the freeze cycle (15 second

delay after FS opens before terminating the freeze cycle). If appliance remains in

freeze longer than 15 sec. after FS removed, replace CB. If appliance switches with

FS removed but would previously not switch out of freeze with FS connected (long

freeze - 3 beep alarm), see "II.E. Float Switch Check and Cleaning."

Note: Normal freeze cycle will last 20 to 40 min. depending on model and conditions.

Cycle times and pressures should follow performance data provided in this

manual. See "VIII.B. Performance Data."

i)

Short Freeze Cycle Diagnosis: Confirm water tank fills and overflows during 1 min.

fill and harvest cycles. If not, check water supply filters, shut-off valve, WV screen.

If water tank empties before 5 min. timer terminates and freeze cycle is short, check

that CV is not leaking by (water flowing down the potable drain). If CV is leaking by,

remove and clean CV, replace rubber seat and spring if necessary. If water tank is

full, see "II.E. Float Switch Check and Cleaning." for erratic operating FS.

7)

Pump-Out Cycle – LEDs 1, 3, and 2 are on (10/20 second pump-out). Timing of the

first pump-out is determined by S4 dip switch 5 & 6. See the table below.

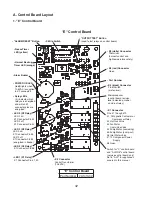

"G" Control Board Settings

S4 Dip Switch Setting

Pump-Out

Frequency

"G" Control Board

No. 5

No. 6

OFF

OFF

Every cycle

After 2nd freeze cycle

ON

OFF

Every 2 cycles

After 3rd freeze cycle

OFF

ON

Every 5 cycles

After 6th freeze cycle

ON

ON

Every 10 cycles

After 11th freeze cycle

Comp and FMR continue, HGV energizes. If S4 dip switch 3 & 4 are set to 3 off

and 4 on, LED 4 turns on and WV and X11 relay energize, energizing X10 relay.

NOTICE!

S4 dip switch 3 & 4 must not be set to 3 off and 4 on. Otherwise, PM

will rotate in freeze cycle direction instead of pump-out direction. FM and LLV

de-energize. PM stops for 2 sec., then reverses for 10/20 sec. depending on pump-out

timer (S4 dip switch 3 & 4) setting. When the pump-out timer terminates, pump-out