19

1. Icemaker

Icemaker Water

Supply Inlet

Minimum Icemaker

Water Supply Line Size

Icemaker Drain

Outlet

Minimum Icemaker

Drain Line Size

Condensation

Drain Outlet

1/2" Female Pipe

Thread (FPT)

1/4" Nominal ID

Copper Water Tubing or

Equivalent

3/4" Female Pipe

Thread (FPT)

3/4" Nominal

ID Hard Pipe or

Equivalent

3/8" OD Hard

Tube

• An icemaker water supply line shut-off valve and drain valve must be installed.

• Be sure there is sufficient extra water supply line and drain line for the appliance to be

pulled out for service.

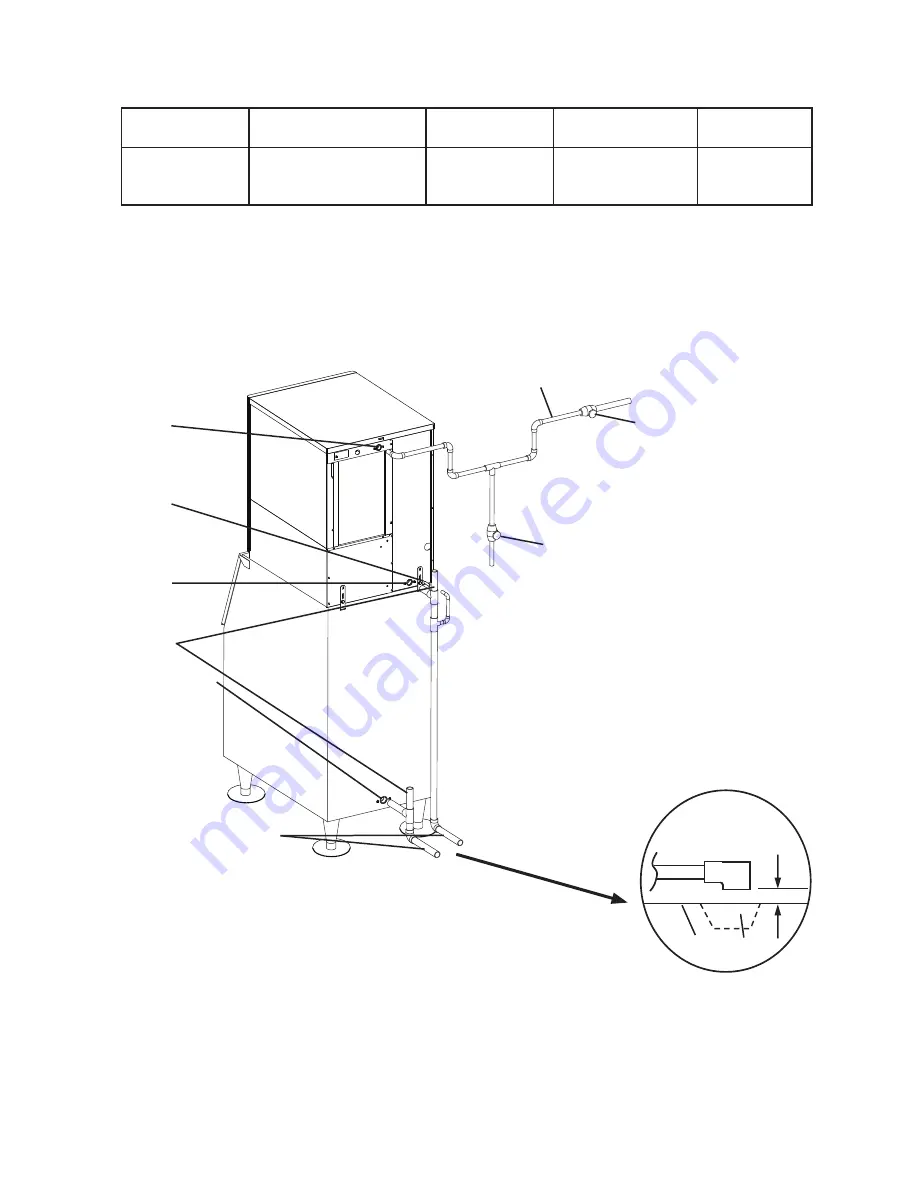

Fig. 7

Icemaker

Icemaker

Water Supply

Inlet

1/2" FPT

Bin Drain Outlet

3/4" FPT

2-inch (5-cm) air gap

Floor Drain

Icemaker

Drain Outlet

3/4" FPT

Ice

Storage

Bin

Icemaker

Condensation

Drain Outlet

3/8" OD Hard Tube

Model Shown:

KM-515MAJ

Vent Tube

Minimum 3/4" Nominal ID

Hard Pipe or Equivalent

Air-Cooled and Remote Models

Drain Valve

Shut-Off Valve

Separate piping to approved

drain. Leave a 2-inch (5-cm)

vertical air gap between the

end of each pipe and the

drain.

Be sure there is sufficient

extra water supply line and

drain line for the appliance

to be pulled out for service.

Minimum 1/4" Nominal ID Copper

Water Tubing or Equivalent