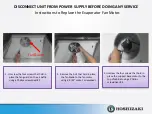

DISCONNECT UNIT FROM POWER SUPPLY BEFORE DOING ANY SERVICE

Instruction to Replace Starting Relay, Overload Protector and Starting Capacitor.

12. Remove the four bolts that

hold in place the electrical

box using a ¼” socket

screwdriver.

13. Insert a flat screwdriver in

the slot of the plastic

electrical box to remove

it from the compressor.

Use the flat screwdriver

as a pry bar to push the

box downward.

14. To remove the overload

protector use a slotted

screwdriver as a pry bar to

pull out it from the

compressor shell.

15. To install the new overload

protector reverse the

previous steps

Summary of Contents for RM-45-SD

Page 1: ...SERVICE MANUAL FOR MODEL RM 45 SD ...

Page 35: ......