WATER TERMINOlOGY

The following chemical terms are used in this Water Quality and Maintenance section. understanding their meaning will help you to better

understand the water maintenance process.

Bromamines:

compounds formed when bromine combines with nitrogen from body oils, urine, perspiration, etc. unlike chloramines, bromamines

have no pungent odor and are effective sanitizers.

Bromine:

A halogen sanitizer (in the same chemical family as chlorine). Bromine is commonly used in stick, tablet, or granular form. see the dos

and DON’Ts of Spa Water Maintenance for additional information.

Calcium Hardness:

The amount of dissolved calcium in the spa water. This should be approximately 50-150 ppm. High levels of calcium can

cause cloudy water and scaling. Low levels can cause harm to the spa equipment.

Chloramines:

compounds formed when chlorine combines with nitrogen from body oils, urine, perspiration, etc. chloramines can cause eye

irritation as well as having a strong odor. unlike bromamines, chloramines are weaker, slower sanitizers.

Chlorine:

An efficient sanitizing chemical for spas. Watkins Manufacturing corporation recommends the use of sodium dichlor-type granulated

chlorine. This type is preferred because it is totally soluble and nearly pH neutral.

Chlorine (or Bromine) Residual:

The amount of chlorine or bromine remaining after chlorine or bromine demand has been satisfied. The residual

is, therefore, the amount of sanitizer which is chemically available to kill bacteria, viruses and algae.

Corrosion

: The gradual wearing away of metal spa parts, usually caused by chemical action. Generally, corrosion is caused by low pH or by water

with levels of TA, cH, pH or sanitizer which are outside the recommended ranges.

DpD:

The preferred reagent used in test kits to measure the Free Available chlorine.

Halogen:

Any one of these five elements: fluorine, chlorine, bromine, iodine and astatine.

mpS:

Monopersulfate is the non-chlorine oxidizer used with the

FReSHWateR

ag+

silver ion purification system.

oxidizer:

The use of an oxidizing chemical is to prevent the buildup of contaminants, maximize sanitizer efficiency, minimize combined chlorine,

and improve water clarity.

pathogen:

A microorganism such as bacterium that cause disease.

pH:

The measure of the spa water’s acidity and alkalinity. The recommended pH for the spa water is 7.2 to 7.6. Below 7.0 (considered neutral), the

spa water is too acidic and can damage the heating system. Above 7.8, the water is too alkaline and can result in cloudy water and scale formation

on the shell and heater.

ppm:

The abbreviation of “parts per million”, the standard measurement of chemical concentration in water. Identical to mg/l (milligrams per liter).

Reagent:

A chemical material in liquid, powder, or tablet form for use in chemical testing.

Sanitizer:

sanitizers are added and maintained at recommended residuals to protect bathers against pathogenic organisms which can cause

disease and infection in spa water.

Scale:

Rough calcium-bearing deposits that can coat spa surfaces, heaters, plumbing lines and clog filters. Generally, scaling is caused by mineral

content combined with high pH. Additionally, scale forms more readily at higher water temperatures.

Shock treatment:

Also known as “super-chlorination” when chorine is used. shock treatment is a process of adding significant doses of a quick

dissolving sanitizer (sodium dichlor is recommended) to oxidize non-filterable organic waste and to remove chloramines and bromamines.

total alkalinity:

The amount of bicarbonates, carbonates, and hydroxides present in spa water. Proper total alkalinity is important for pH control.

If the TA is too high, the pH is difficult to adjust. If the TA is too low, the pH will be difficult to hold at the proper level. The desired range of TA in spa

water is 40 to 120 ppm.

MAINTENANCE ANd SPA CARE

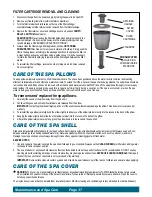

FIlTER MAINTENANCE

At least once a week, check and clean the skimmer basket and weir to ensure proper filter flow. Remove leaves, foreign matter, and debris. It

is very important to keep your spa filter cartridge clean and free of particles to ensure proper water flow. A clean filter permits the hydrotherapy

system to function properly and also allows more efficient filter cycles. depending on how frequently your spa is used, we recommend cleaning

the spa filter cartridge every four weeks. If this is not done, the filter may clog and restrict water flow, which causes improper filtration and poor jet

performance.

WaRNING:

The frequency and duration of use, and the number of occupants all contribute to determining the appropriate time between filter

cleanings. More use means that more frequent filter cleanings will be required.

page 36

Maintenance and Spa Care

Summary of Contents for 2014 REL

Page 1: ...2014 Owner s Manual...

Page 47: ......