-

6

-

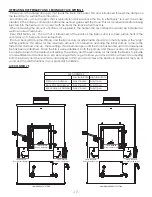

Furnace Installation

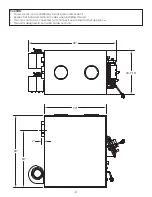

Dimension

Inch

mm

A

Backwall to Furnace

28

712

B

Sidewall to Furnace

16

407

C

Sidewall to Flue

25

635

D

Backwall to Flue

18

458

E

Supply Duct (first 6 feet)

6

153

F

Supply Duct (after first 6 feet)

1

26

G

Minimum Duct height

8

204

H

Top of Door to Ceiling

48

1220

J

Minimum Ceiling Height

77

1956

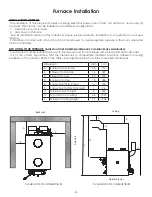

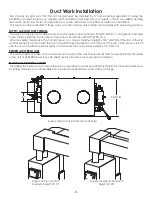

INSTALLATION OPTIONS

The installation of this furnace includes supplying electrical power, return (fresh air) ductwork, and supply air

ductwork. This furnace may be installed in two different configurations.

1. Stand alone wood furnace

2. Add-on wood furnace

See kit installation section in this manual to ensure proper assembly, installation and operation of your new

furnace.

If installing in an area with a fan it should not be allowed to create negative pressure in the room where the

furnace is installed.

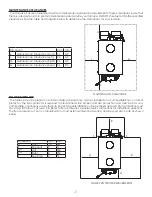

LOCATING YOUR FURNACE

(INSURE THAT THE REQUIRED MAINTENANCE CLEARANCES ARE MAINTAINED)

Your furnace must be installed as shown in this manual and in compliance with all local and national codes.

It is of the utmost importance that the clearances to combustible materials be strictly adhered to during

installation of the furnace. Refer to the table and diagrams below for minimum required clearances.

Back wall

Side w

all

Side w

all

Ceiling

Floor Protector

C

B

A

M

L

N

K

E

F

G

H

J

D

Q

O

R

P

S

S

Back wall

Side w

all

Side w

all

Ceiling

Floor Protector

C

B

A

M

L

N

K

E

F

G

H

J

D

Q

O

R

P

S

S

CLEARANCE TO COMBUSTIBLES

CLEARANCE TO COMBUSTIBLES

Summary of Contents for HB1440E

Page 9: ... 9 CENTRAL INSTALLATION Air Filter Replacement ...

Page 27: ...Notes ...