2

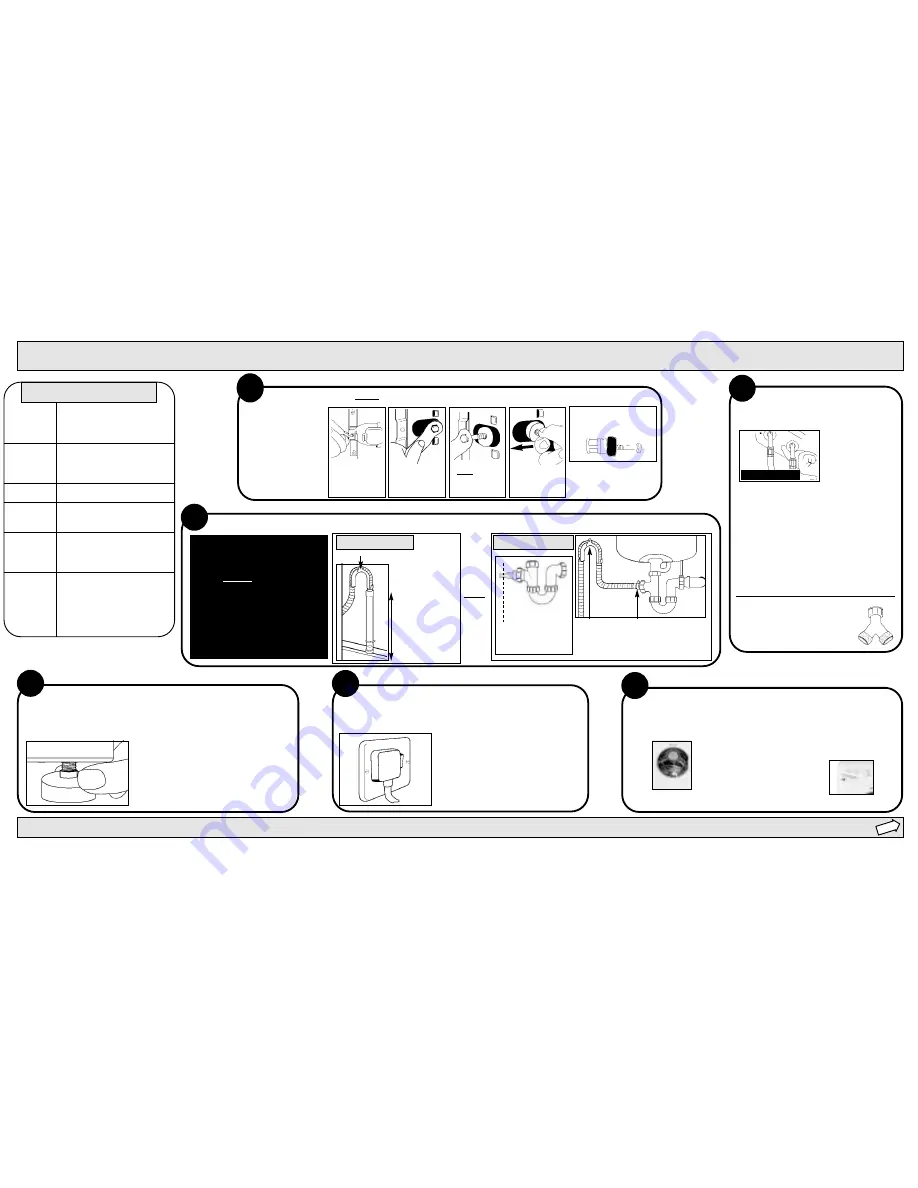

CONNECT TO THE WATER

SUPPLY...

Installation

ii

i

3

DRAINAGE SYSTEM... we recommend one of the following:

4

LEVEL?...

NOTE: ALTHOUGH YOU MAY NEED TO

MOVE THE HOOKED END SUPPORT

ALONG THE GREY DRAINAGE HOSE,

DO NOT REMOVE IT.

WHICHEVER DRAINAGE METHOD

YOU USE, MAKE SURE THAT THE

HOOKED END SUPPORT IS FIXED

LEVEL TO, OR ABOVE THE ‘PLUMBING

INDICATOR LINE’*

(*see Getting to Know your Appliance)

PLEASE USE THE NEW HOSES SUPPLIED, FITTED

TO THE MACHINE.

If you have no hot water supply...

Old hoses may

cause leaks due to

worn out washers

or may split due to

water pressure

.

YOUR MACHINE WILL BE NOISY IF THE TWO FRONT FEET ARE NOT

ADJUSTED SO THE MACHINE STANDS FIRM AND LEVEL.

Check both hot

and cold water

supplies are

running freely...

A cold fill adaptor is available from

your local Hotpoint authorised

Service Centre or by calling the

Genuine Parts & Accessories Hotline

(see KEY CONTACTS).

Connect fill hoses to the

water supply taps:

Red or Grey Hose end to

Hot and Blue Hose end

to Cold.

TURN BOTH TAPS ON...

iv

iii

Check the hoses

at least once a

year. Replace any

that show signs of

cracking, they

might burst due

to water pressure.

Water pressure at the tap

must be in the range...

Max. 1Mpa (10 bar) and

Min. 0.05Mpa (0.5 bar)

- Move your machine into final location.

Take care not to trap or kink the hoses.

- Turn one

or

both front feet clockwise until

the machine stands firm and level.

The spring on each foot will stop them

coming loose.

If it is placed on a fitted carpet, adjust the feet

to ensure that there is adequate ventilation

beneath the washing machine.

1

REMOVE TWO TRANSIT FIXINGS...

Follow these instructions to remove the TWO transit fixings.

IMPORTANT:

Situated, one either

side of the rear panel,

both transit bolts

(complete with

spacers) MUST be

removed before use...

Failure to do so may

cause damage to

your machine!

DO NOT REMOVE!

STANDPIPE METHOD

UNDER SINK METHOD

TECHNICAL DETAILS

OR

Attach the GREY

drainage hose to the

under sink drainage

unit securely, using a

hose clip.

Fix the hooked

end support at

a minimum

800mm from

the floor.

cut off the blocked

end of the under sink

drainage unit.

6

READY...

TO CHECK ALL PARTS OF THE INSTALLATION AND TO THOROUGHLY

CLEAN THE INSIDE OF YOUR MACHINE:

RUN PROGRAMME ‘B’ (

refer to ‘Programme Selection’, STEP 4

).

5

CONNECT TO THE POWER SUPPLY...

PLUG YOUR MACHINE INTO AN ELECTRICAL SOCKET WHICH IS

EASILY ACCESSIBLE.

SWITCH ON

NOTE: Hotpoint recommend extension

leads are not used.

NOTE: The mains cable must only be

replaced by an authorised serviceman.

WITHOUT ANY LAUNDRY

WITHOUT ANY DETERGENT

and

THIS WILL TAKE APPROXIMATELY 2hours 20minutes TO COMPLETE

.............................

Standpipe height:

minimum 500mm

from the floor.

Insert drainage hose

approximately 100mm

into the standpipe.

✗

✗

It is important the transit

bolt and spacer come out

intact (see pic).

For safety, replace both

plastic covers over the

holes left by removing

the two bolts.

Use a crosshead

screwdriver to

remove the

plastic cover.

Unscrew the

bolt using a

13mm spanner.

STOP when 3

threads can be

seen.

Hold, slide

across and pull

to remove.

800mm

from floor

Hooked End Support

STEP 2

The inclination of the machine, measured on the top, must not exceed 2˚.

Models

Dimensions

Capacity

Electric

Connections

Spin Speed

Control

programmes

according to

IEC456

directive

WF645,WF640,

WF630,

and WF620

59.5cm wide

85cm high

60cm deep

from 1 to 6kg

voltage 220/230 Volts 50Hz

maximum absorbed power 1700W

up to 1400rpm - WF645 & WF640

up to 1300rpm - WF630

up to 1200rpm - WF620

programme D

temperature 60˚C

run with a 6kg load