2

GB

Installation

Levelling your appliance correctly will provide it with sta-

bility and avoid any vibrations, noise and shifting during

operation. If it is placed on a fitted or loose carpet, adjust

the feet in such a way as to allow enough room for ventila-

tion beneath the washing machine.

Electric and water connections

Connecting the water inlet hose

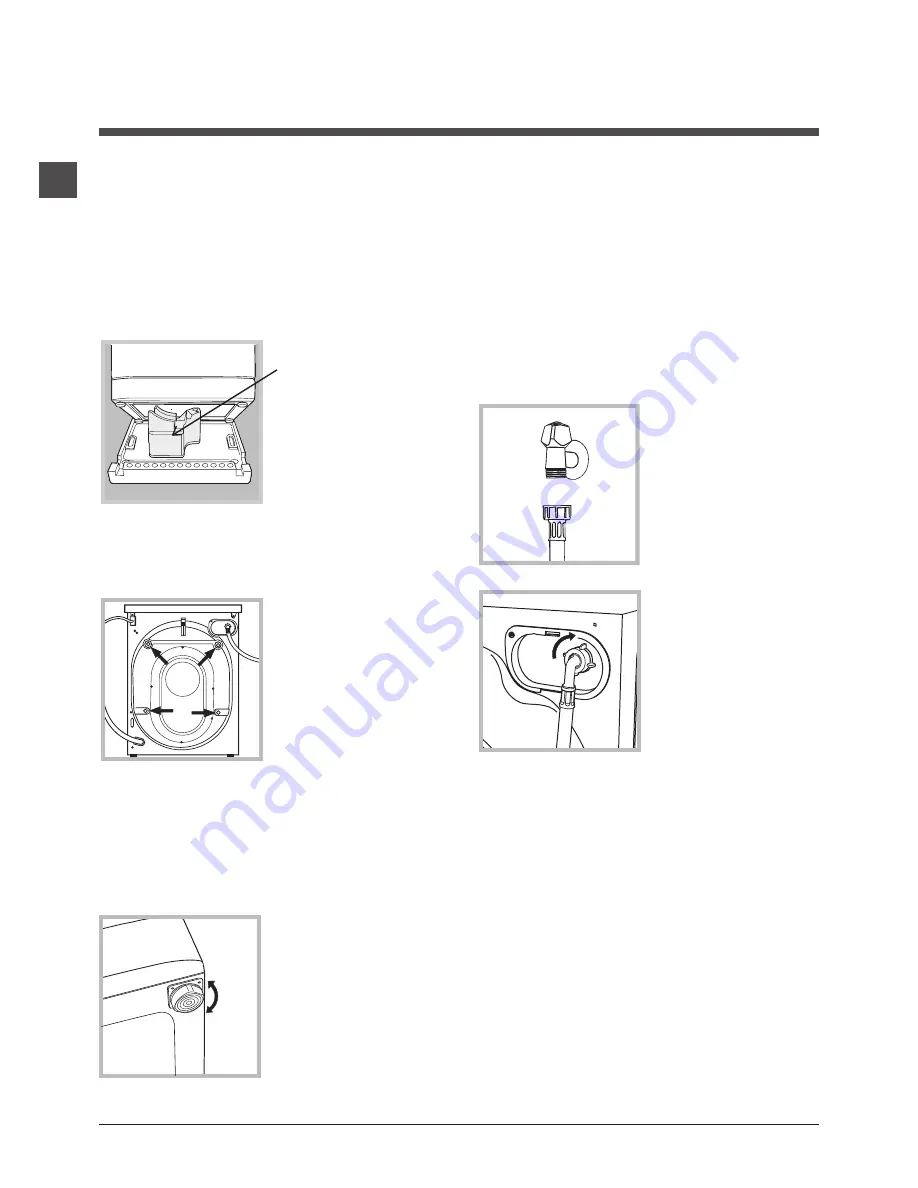

1. Connect the supply pipe

by screwing it to a cold

water tap using a 3/4 gas

threaded connection

(see

figure).

Before performing the con-

nection, allow the water to

run freely until it is perfectly

clear.

2. Connect the other end of

the water inlet hose to the

washing machine,

screwing it onto the applian-

ce’s cold water inlet, situated

on the top right-hand side

on the rear of the appliance

(

see figure).

3. Make sure there are no kinks or bends in the hose.

!

The water pressure at the tap must be within the values

indicated in the Technical details table

(on the page 5).

!

If the water inlet hose is not long enough, contact a spe-

cialist store or an authorised serviceman.

!

Ensure that the supply taps are allowing water through.

Old taps may seize in the closed position and thus pre-

vent water reaching the machine.

!

Never use second-hand or old inlet hoses; use the pro-

ducts supplied with the machine.

!

Keep this instruction manual in a safe place for future

reference. Should the appliance be sold, transferred or

moved, make sure the instruction manual accompanies

the washing machine to inform the new owner as to its

operation and features.

!

Read these instructions carefully: they contain vital infor-

mation on installation, use and safety.

Unpacking and levelling

Unpacking

!

This is a separate part of

the polystyrene base and

should be removed with

the base.

!

IMPORTANT check

when unpacking your

machine.

1. Unpack the washing machine.

2. Check whether the washing machine has been dama-

ged during transport. If this is the case, do not install it and

contact your retailer.

3. Remove the 4 protective

screws and the rubber bush

with the respective spacer,

situated on the rear of the

appliance (see also the

installation leaflet).

4. Seal the gaps using the plastic plugs provided.

5. Keep all the parts: you will need them again if the wa-

shing machine needs to be moved to another location.

!

Packaging materials are not children’s toys.

Levelling

Your machine may make a considerable amount of noise if

the two front feet have not been adjusted correctly.

1. Install the washing machine

on a flat sturdy floor, without

resting it up against walls,

cabinets or anything else.

2. If the floor is not perfectly level, compensate for any

unevenness by tightening or loosening the adjustable front

feet

(see figure);

the angle of inclination, measured accor-

ding to the worktop, must not exceed 2°.