3

GB

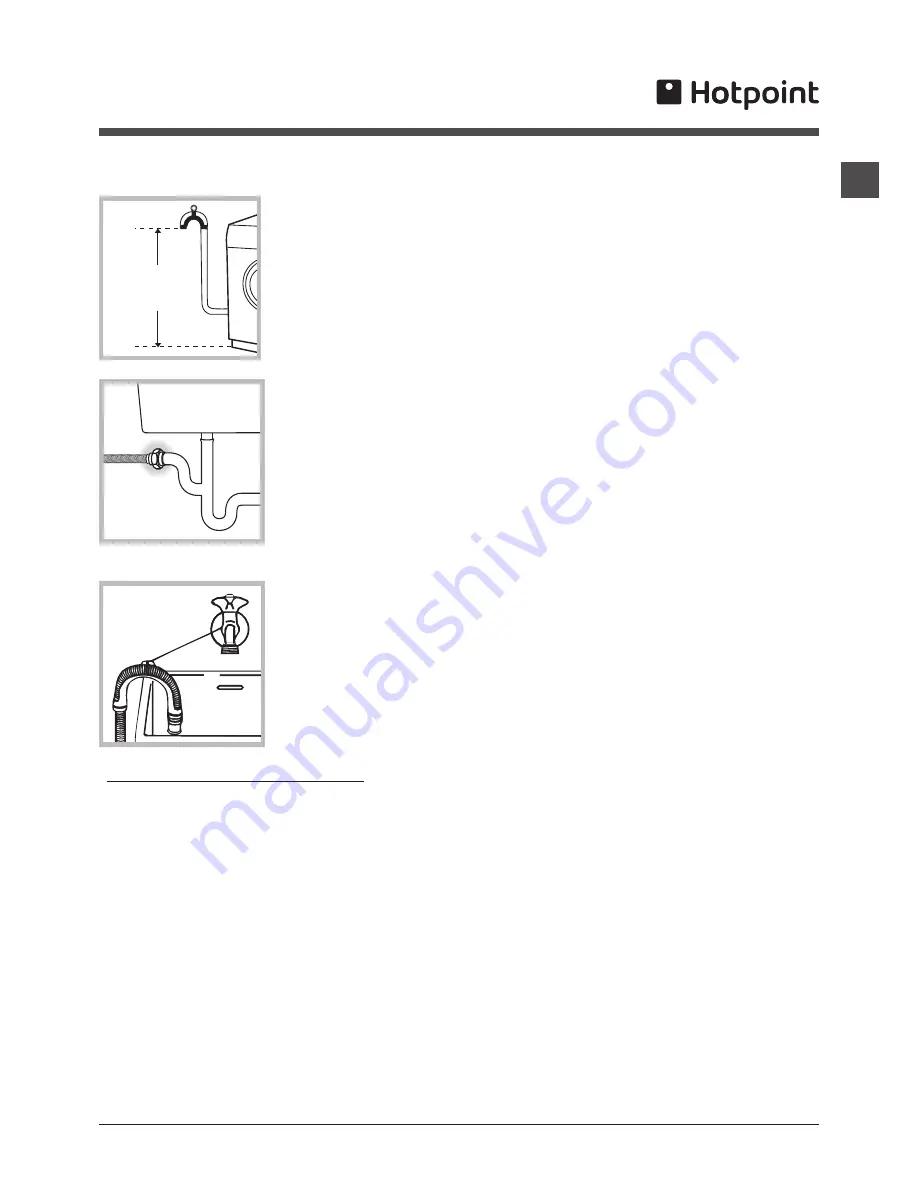

Connecting the drain hose

Connect the drain hose,

without bending it, to a

draining duct or a wall drain

situated between 65 and

100 cm from the floor;

The drain hose may be

connected to an under-

sink trap. Before connec-

ting the drain hose from

the machine ensure that

any blanks or removable

ends have been taken off

the spigot.

If it is placed over the edge

of a basin or sink be sure

the free end of the hose

should not be underwater.

!

We advise against the use of hose extensions; in case of

absolute need, the extension must have the same diameter

as the original hose and must not exceed 150 cm in length.

Ensure that if the drain hose is pushed into a standpipe, that

the end does not go down more than 15cms (6 inches). If

the hose is pushed down too far, this may cause the machi-

ne to self -syphon ie. continuously empty as it is filling.

Electric connection

Before plugging the appliance into the mains socket, make

sure that:

•

the socket is earthed and in compliance with the appli-

cable law;

•

the socket is able to sustain the appliance’s maximum

power load indicated on the Technical Data Plate fixed

on the machine

;

• the supply voltage is included within the values indica-

ted on the Technical Data Plate fixed on the machine.

• the socket is compatible with the washing machine’s

plug. If this is not the case, replace the socket or the

plug.

Your appliance is now supplied with a 13 amp fused plug

it can be plugged into a 13 amp socket for immediate use.

Before using the appliance please read the instructions

below.

WARNING - THIS APPLIANCE MUST BE EARTHED.

THE FOLLOWING OPERATIONS SHOULD BE CARRIED

OUT BY A QUALIFIED ELECTRICIAN.

Replacing the fuse:

When replacing a faulty fuse, a 13 amp ASTA approved

fuse to BS 1362 should always be used, and the fuse

cover re-fitted. If the fuse cover is lost, the plug must not

be used until a replacement is obtained.

Replacement fuse covers:

If a replacement fuse cover is fitted, it must be of the

correct colour as indicated by the coloured marking or the

colour that is embossed in words on the base of the plug.

Replacements can be obtained directly from your nearest

Service Depot.

Removing the plug:

If your appliance has a non-rewireable moulded plug and

you should wish to re-route the mains cable through parti-

tions, units etc., please ensure that either:

the plug is replaced by a fused 13 ampere rewireable plug

bearing the BSI mark of approval.

or:

the mains cable is wired directly into a 13 amp cable out-

let, controlled by a switch, (in compliance with BS 5733)

which is accessible without moving the appliance.

Disposing of the plug:

Ensure that before disposing of the plug itself, you make

the pins unusable so that it cannot be accidentally inserted

into a socket.

Instructions for connecting cable to an alternative plug:

Important: the wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow

Earth

Blue

Neutral

Brown

Live

65 - 100 cm

Where it connects to

the waste water pipe

cut end off spigot or

remove the blanking cap