26

Chapter 5

Display and Operation

Subject to technical changes

Rev. 1.01.08

5.5

Messages & Displays

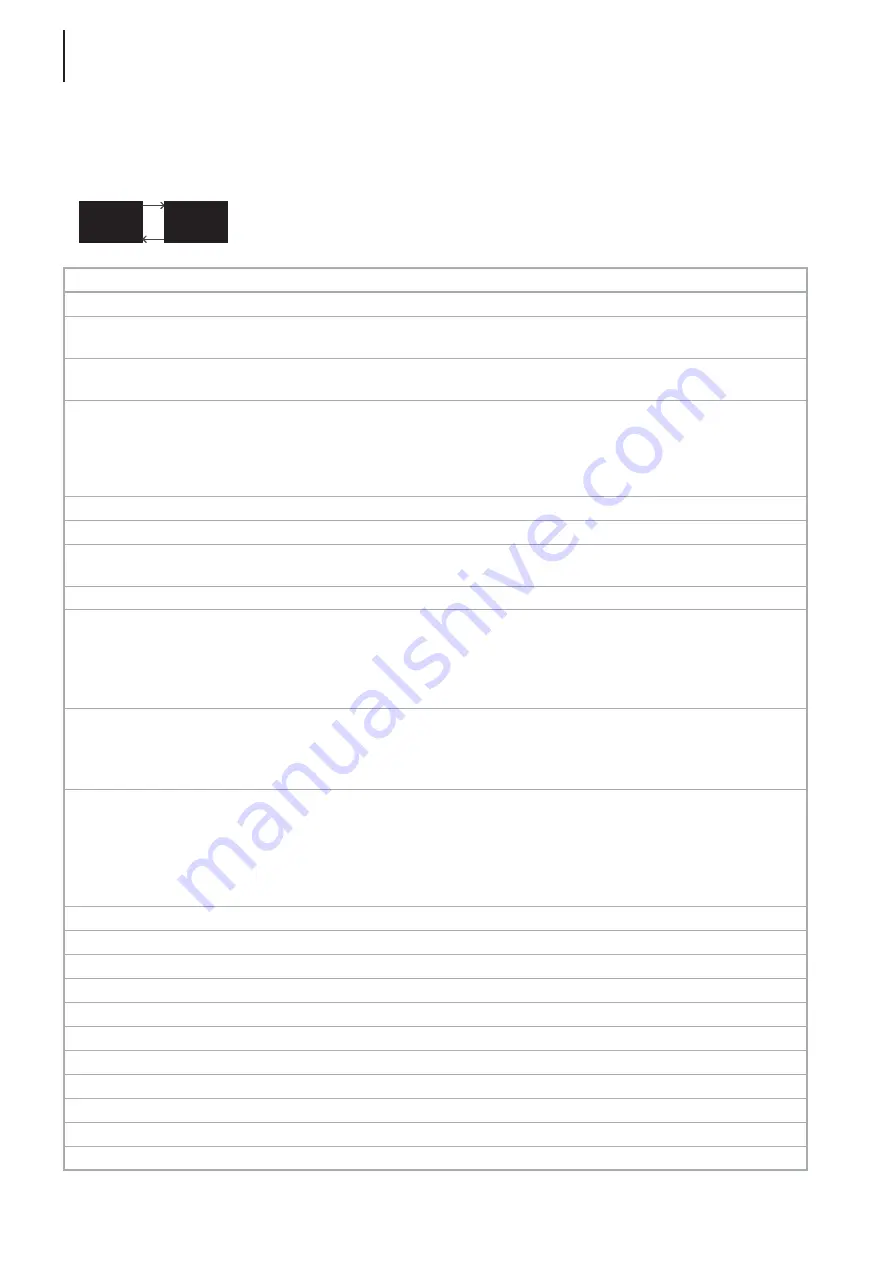

5.5.1 Status Messages

Status messages in case of alarm status or certain operating status will be al--

ternately displayed with the actual value as additional information.

Display

Meaning

Alarm

Status

Fault Correction

tCbr

Sensor break

x

Control thermocouple or wiring.

tCrC

Sensor incorrect polarity

x

Thermocouple wiring wrong. Correct

wiring.

IdE

Identification error

x

Cool zone down and then start identifi--

cation again.

drl

Temperature drift

x

Determination of heating control pa-

ra-meters can not start because the

zone was influenced by another zone

at identification. Start identification

again.

Id

Identification heating

x

IdC

Identification cooling

x

IdS

Start up phase automatic adaptation of

cooling

x

mAnU

Manual mode

x

AL

Measuring range exceeded (tempera--

ture alarm)

x

Control heating unit and power control--

ler (e.g. SSR).

Control if the sensor related with the

heating unit is connected with the con--

troller.

SSr

Current alarm heating off

x

Control power controller (e.g. SSR).

Control if the current transformer relat-

ed to the heating unit is connected with

the controller.

tCSC

Sensor alarm

x

Control thermocouple wiring.

Control parameter setting

Ó

[P023]tC.ti

- Testing Period for Manual Short Cir-

cuit Supervision of Sensor (page 30)

and

Ó

[P022]tC.AL - Autom. Short Cir-

cuit Supervision of Sensor (page 30).

rAmP

Ramp

x

SP4

Setpoint Value 4

x

SP3

Setpoint Value 3

x

SP2

Setpoint Value 2

x

Ar.

Automatic ramp slowest zone

x

Ar Automatic

ramp

x

ArE

Error automatic ramp

x

ArE.

Error automatic ramp slowest zone

x

Err1

Error in calibration data

x

Send controller to

H

otset Gmb

H

.

Err2

Error in attributes

x

Send controller to

H

otset Gmb

H

.

Err3

Error in channel data

x

Send controller to

H

otset Gmb

H

.

1999

100

tCbr

100

Summary of Contents for hotcontrol C248

Page 2: ......